Pre-expanded beads of flame-retardant polyolefin resin and molded object thereof by in-mold foaming

A technology of polyolefin resin and pre-expansion, which is applied in the field of in-mold foam molding products and flame-retardant polyolefin resin pre-expanded particles, which can solve the problem of foaming moldability and mechanical strength decline, pre-expansion Particle fusion and bonding obstacles, no record of application, etc., to achieve good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1

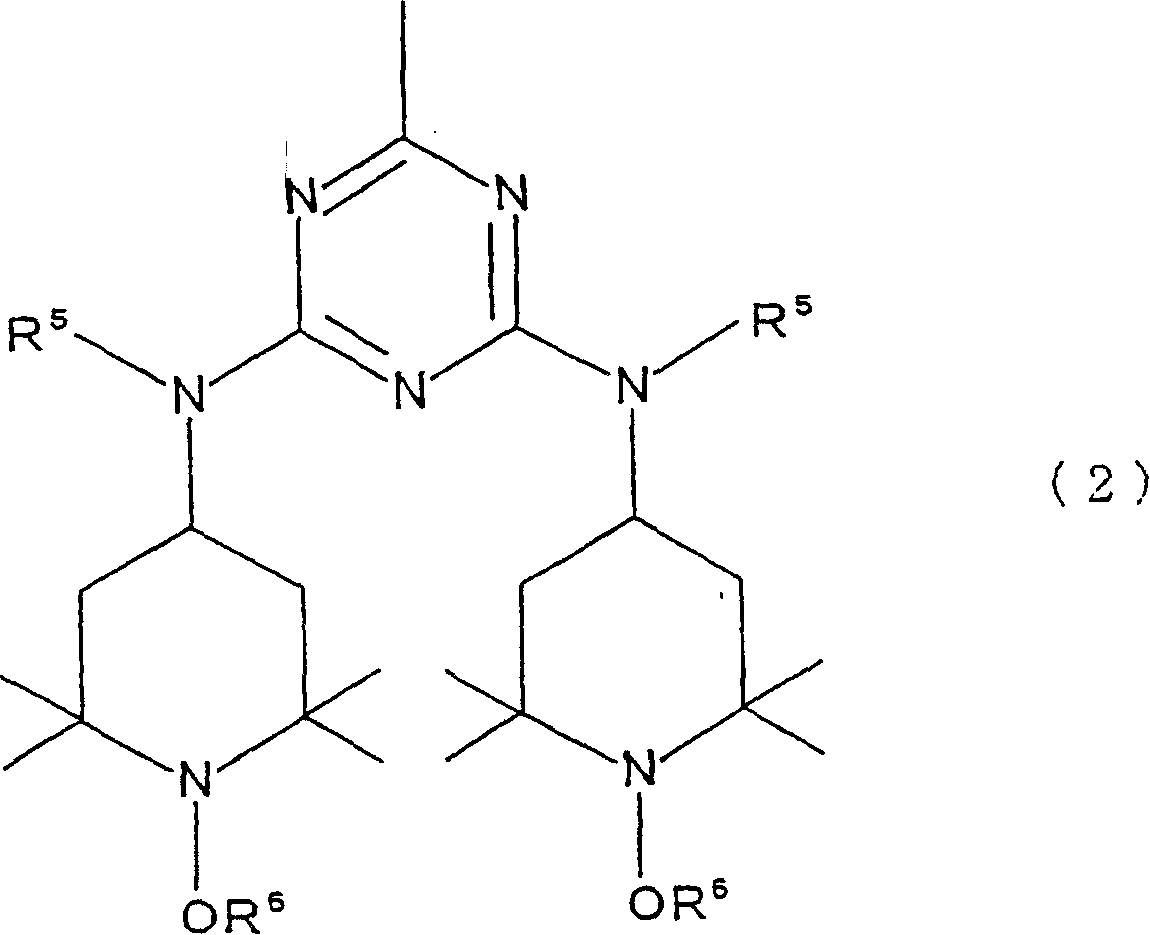

[0115] With ethylene-propylene random copolymer (ethylene content rate is 2.5% by weight), MI=6.0g / 10 minutes) 100 parts, and by chemical formula (3):

[0116] wxya 2 CH 2 CH 2 NRCH 2 CH 2 NHCH 2 CH 2 CH 2 NHR (3)

[0117] (In the formula, R represents by the following formula:

[0118]

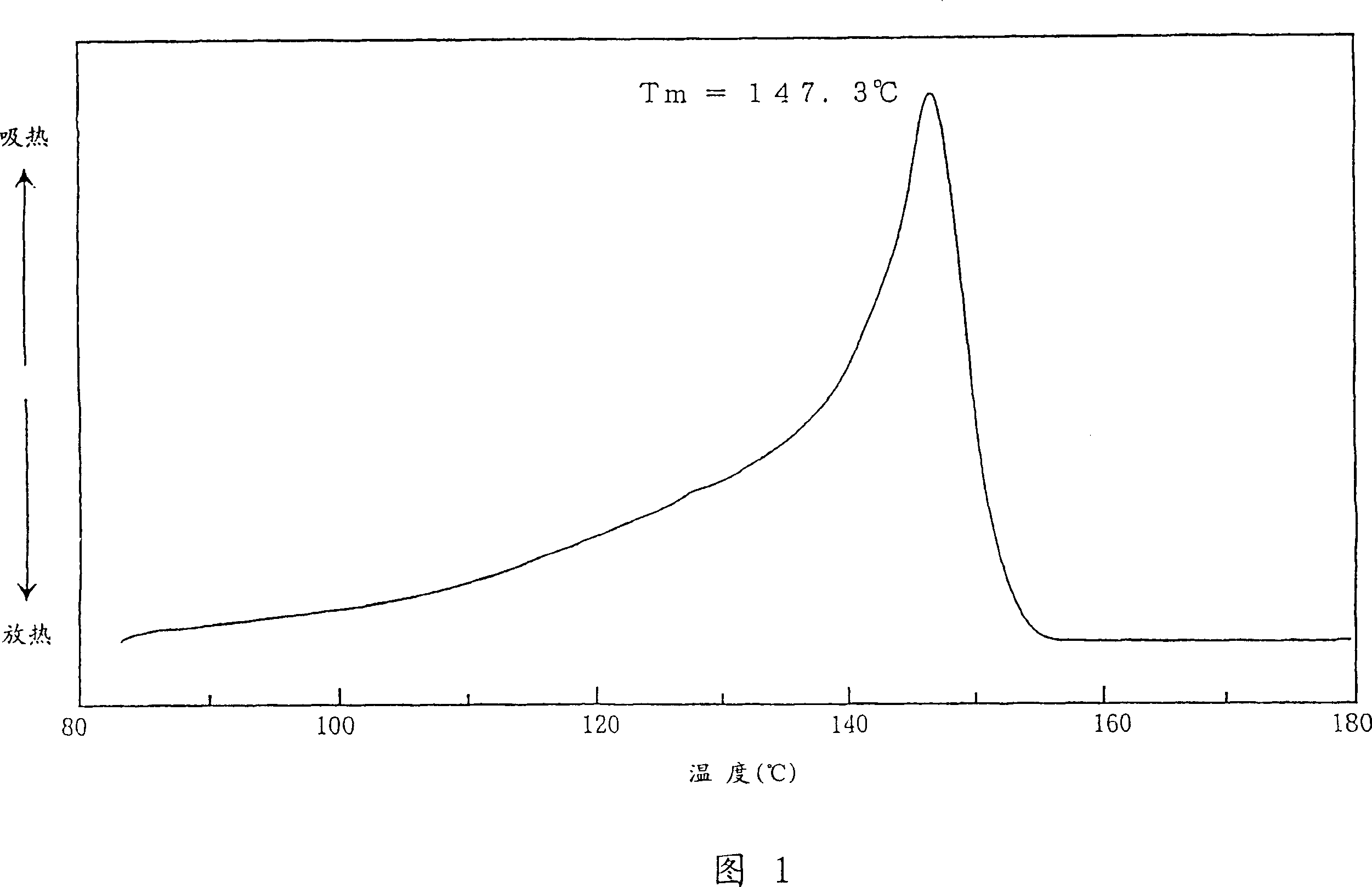

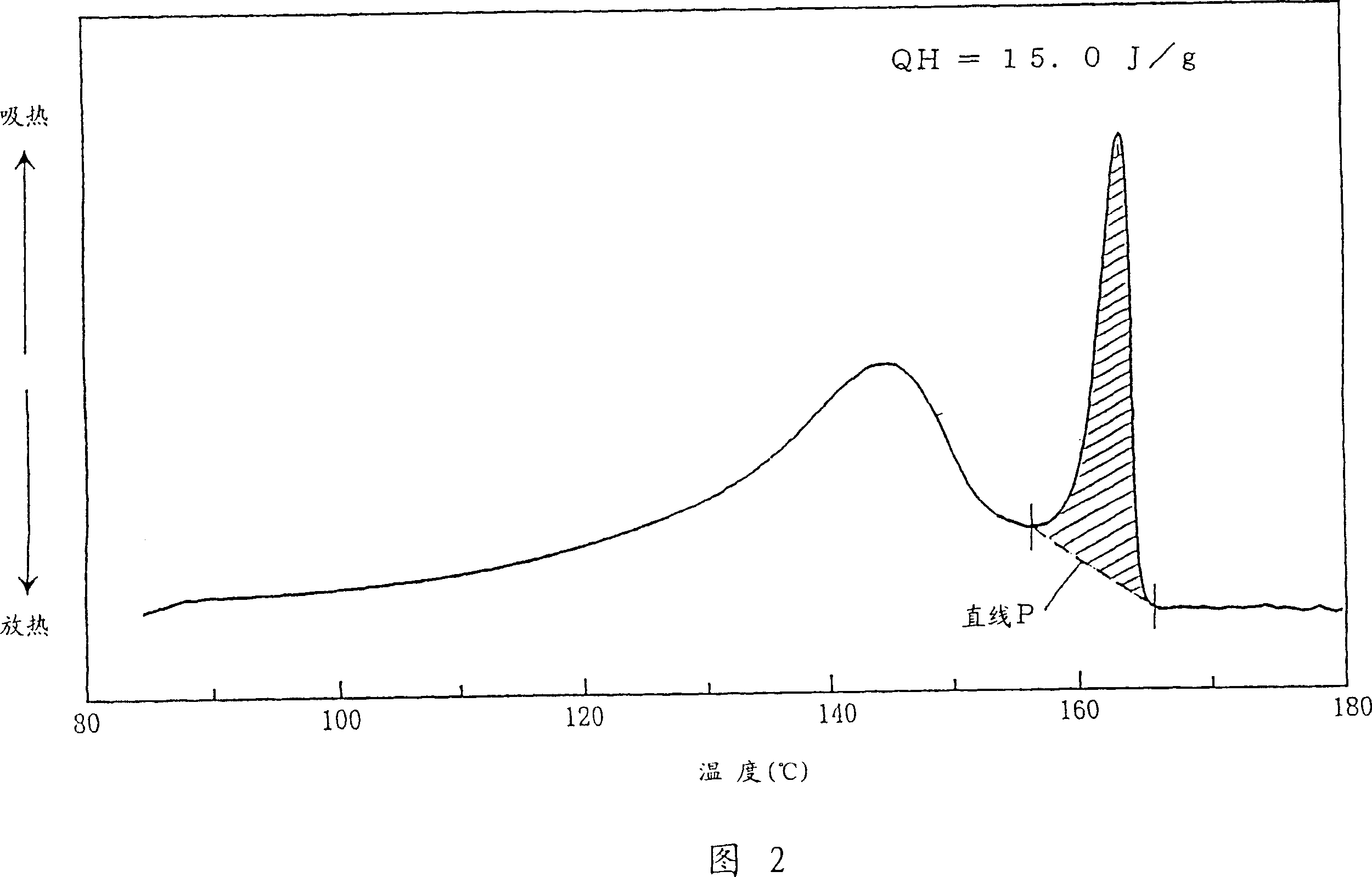

[0119] The sterically hindered phenolic ether flame retardant (trade name: CGL116, チバペスペシヤルテイイラミカルズ (Ciba Specialty Chemicals)) and the carbon black as the colorant are mixed according to the amount shown in Table 1, and then a single After kneading by a shaft extruder, it was pelletized to produce resin pellets (1.8 mg / pellet). The melting point of the obtained polyolefin resin pellets was 147.3°C.

[0120] 100 parts of this resin particle and 9.3 parts of isobutane and dispersant (containing 2 parts of powdery basic tricalcium phosphate and 300 parts of water of n-paraffin sodium sulfonate 0.05 part) are packed together in 10 liters of pressure vessels, The inside of the contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com