Apparatus and method for removing contaminants from fine grained soil, clay and silt

A kind of equipment and technology for polluting particles, which can be used in equipment for removing pollutants and in the field of removing pollutants, which can solve problems such as limited effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

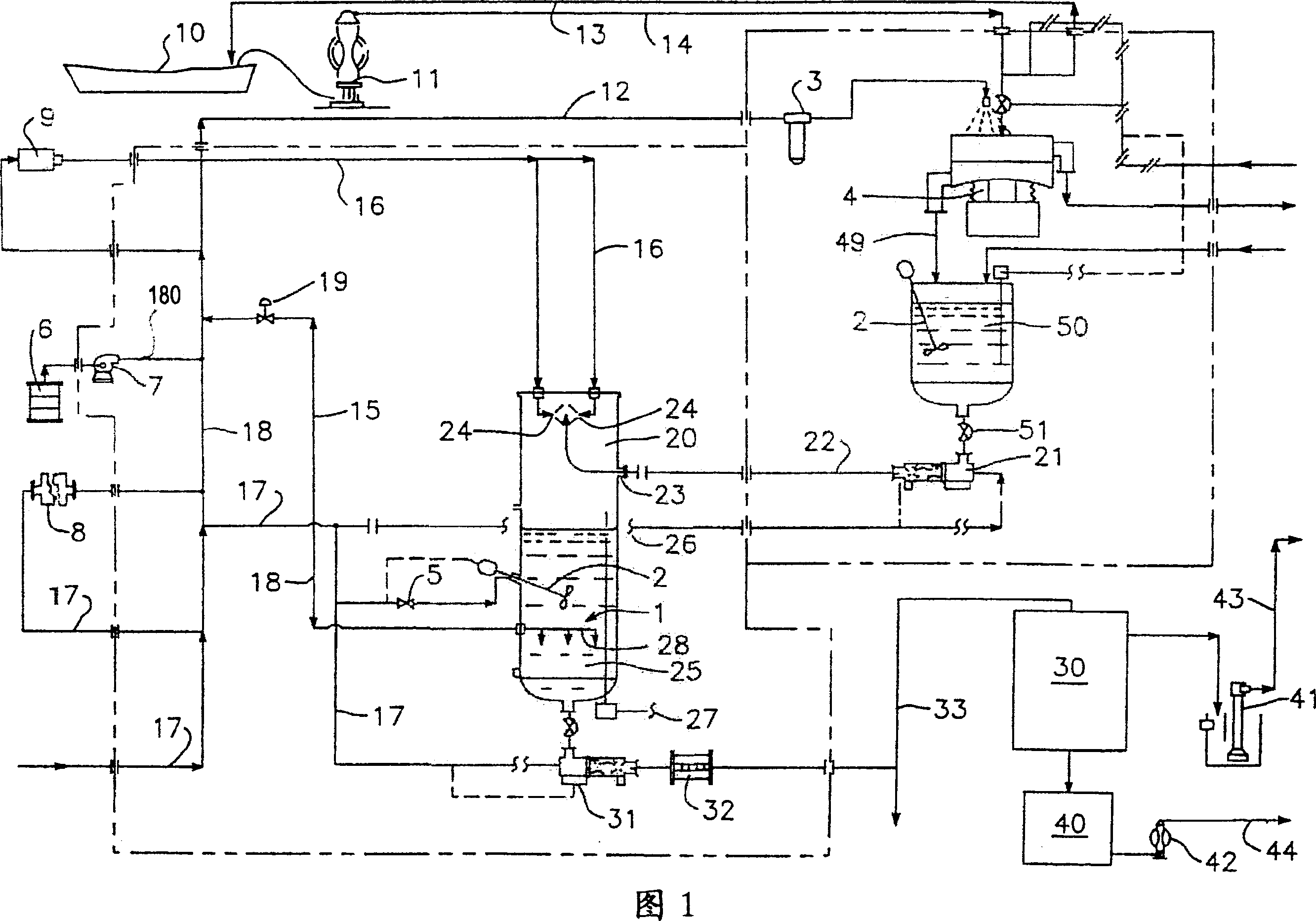

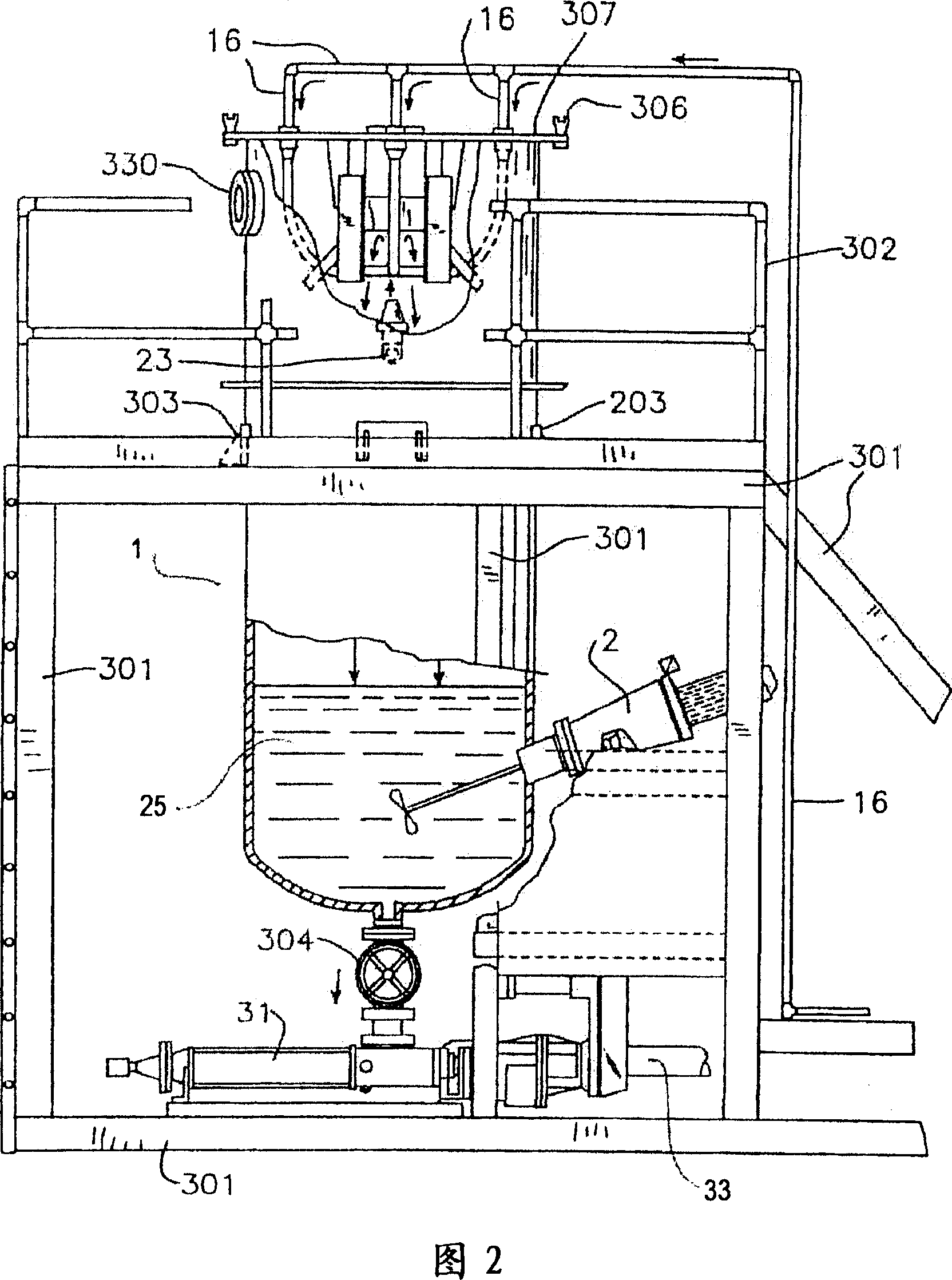

[0101] The equipment constructed for this example was a continuous flow unit for cleaning fines and clays. Utilizing a series of collision cells working in parallel, throughputs of up to 80 to 100 cubic yards per hour can be achieved.

[0102] Sediments contaminated with polyaromatic hydrocarbons (PAH) above 4000ppm were selected for cleaning. The deposition of the pollution

[0103] Most of the material (81%) is medium silt with an average particle size of less than 38 microns. Sediment is treated first to separate large particulate material. Transfer the large particle material to a standard large particle washer for disposal. The material passing through the iron grid screen flows to the pulverizer and then enters the pretreatment tank. The pulverized material is mixed, heated and mixed with water and biosurfactant chemicals. This forms the slurry.

[0104] The slurry is then sent to a vibrating screen separator, which screens the particles into two groups. Material ...

Embodiment 2

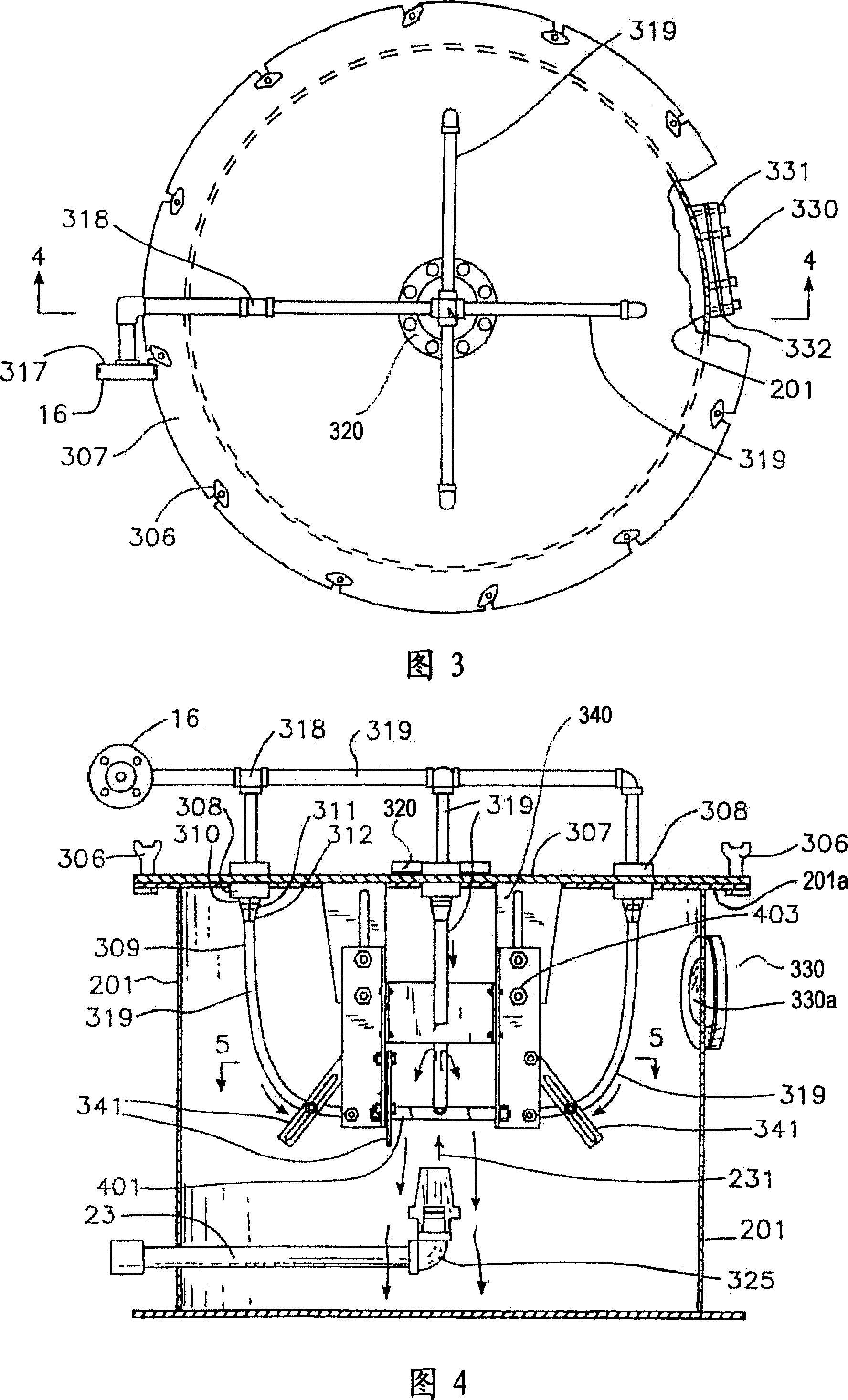

[0121] In this embodiment, particles above 50 mesh and below 50 mesh are selected. In this example, the temperature of the cleaning solution was maintained at 100°F (37.78°C). The number of nozzle devices used was four. The intersection angle of the plane defined by the nozzle discharge flow and the input flow was maintained at 135 degrees.

[0122] Tests were conducted at discharge pressures of 6000 psi (41.4 MPa), 8000 psi (55.2 MPa) and 12000 psi (82.7 MPa) for each nozzle. It has been determined that when the particle size is less than 50 mesh and the discharge pressure of the nozzle device is between 8000 (55.2MPa) and 12000psi (82.7MPa), the decontamination efficiency of 99% is generated for particles passing through 200 mesh. See Table 1.

[0123] Table 1

[0124]

Embodiment 3

[0126] In this embodiment, the number of nozzles used is 4, and the pressure of each nozzle discharging the cleaning liquid is 6000 psi (41.4 MPa). The discharge angle between the plane defined by the discharge flow of the nozzle arrangement and the input flow is maintained at 90 degrees.

[0127] In this example, the temperature of the cleaning solution was tested in a range around 100°F (37.78°C). These temperatures were less effective for both large and small particles (see Table 2).

[0128] Table 2

[0129] Sediment Cleaning Efficiency

[0130] It was determined that when removing contaminants from the oils used in this example, the temperature must be maintained between 100 and 160°F ((37.78°C to 71.11°C) to achieve 99% efficiency on particles passing through 200 mesh. This Other applications of the equipment may use higher or lower cleaning fluid optimum temperatures, depending on the type of contaminant and the average size of the particles being treated in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com