Efficient printing ink cleaning agent and preparation process thereof

A technology for printing ink and preparation process, applied in the field of printing, can solve problems such as affecting printing quality, and achieve the effects of good printing effect, good stability and high decontamination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

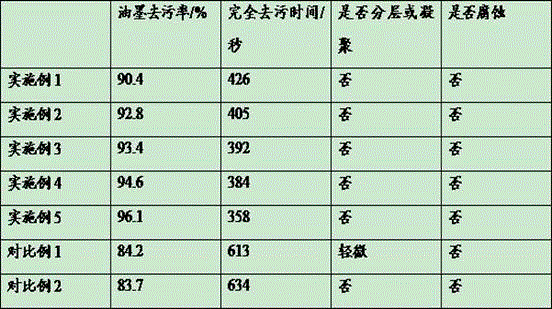

Examples

Embodiment 1

[0021] A high-efficiency printing ink cleaning agent, comprising the following components in parts by weight: 3 parts of disodium cocoamphodiacetate, 2 parts of octadecyl dihydroxyethyl amine oxide, dodecylbenzenesulfonic acid 3 parts of sodium, 1 part of ferulic acid, 5 parts of soybean saponin, 3 parts of sodium oil sulfonate, 2 parts of nonylphenol polyoxyethylene ether, 3 parts of thiourea dioxide, 1 part of α-lipoic acid, sodium tripolyphosphate 4 parts, 7 parts of isopropyl myristate, 3 parts of zinc naphthenate, 1 part of methylisothiazolinone, 1 part of diethylene glycol methyl ether, 5 parts of propylene glycol, 7 parts of ethanol, 15 parts of deionized water .

[0022] The preparation process of the above-mentioned high-efficiency printing ink cleaning agent comprises the following preparation steps:

[0023] (1) Add ferulic acid, soybean saponin, sodium dodecylbenzenesulfonate, sodium tripolyphosphate, and α-lipoic acid into the mixed solution of deionized water an...

Embodiment 2

[0028] A high-efficiency printing ink cleaning agent, comprising the following components in parts by weight: 9 parts of disodium cocoamphodiacetate, 8 parts of octadecyl dihydroxyethyl amine oxide, dodecylbenzenesulfonic acid 9 parts of sodium, 5 parts of ferulic acid, 10 parts of soybean saponin, 8 parts of sodium oil sulfonate, 9 parts of nonylphenol polyoxyethylene ether, 7 parts of thiourea dioxide, 5 parts of α-lipoic acid, sodium tripolyphosphate 8 parts, 15 parts of isopropyl myristate, 6 parts of zinc naphthenate, 4 parts of methylisothiazolinone, 6 parts of diethylene glycol methyl ether, 12 parts of propylene glycol, 18 parts of ethanol, 35 parts of deionized water .

[0029] The preparation process of the above-mentioned high-efficiency printing ink cleaning agent comprises the following preparation steps:

[0030] (1) Add ferulic acid, soybean saponin, sodium dodecylbenzenesulfonate, sodium tripolyphosphate, and α-lipoic acid into the mixed solution of deionized ...

Embodiment 3

[0035] A high-efficiency printing ink cleaning agent, comprising the following components in parts by weight: 4 parts of disodium cocoamphodiacetate, 3 parts of octadecyl dihydroxyethyl amine oxide, dodecylbenzenesulfonic acid 4 parts of sodium, 2 parts of ferulic acid, 6 parts of soybean saponin, 4 parts of sodium oil sulfonate, 4 parts of nonylphenol polyoxyethylene ether, 3 parts of thiourea dioxide, 2 parts of α-lipoic acid, sodium tripolyphosphate 5 parts, 7 parts of isopropyl myristate, 4 parts of zinc naphthenate, 2 parts of methylisothiazolinone, 3 parts of diethylene glycol methyl ether, 7 parts of propylene glycol, 9 parts of ethanol, 22 parts of deionized water .

[0036] The preparation process of the above-mentioned high-efficiency printing ink cleaning agent comprises the following preparation steps:

[0037] (1) Add ferulic acid, soybean saponin, sodium dodecylbenzenesulfonate, sodium tripolyphosphate, and α-lipoic acid into the mixed solution of deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decontamination rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com