Modified functional silica gel material as well as preparation method and application thereof

A technology of sexual function and silica gel, applied in the field of modified functionalized silica gel materials, it can solve the problems of increasing cement curing volume, poor selectivity, slow adsorption rate, etc., to improve thermal stability and radiation resistance, high load and adsorption Capacity, the effect of increasing the load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

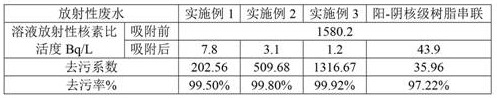

Examples

Embodiment 1

[0042] Preparation of polyfunctional cross-linked amino-functionalized silica gel shown in structural formula III: the solution of 3-chloropropylthiopropyltrimethoxysilane (0.3mol) and diethylenetriamine (0.6mol) was heated to 70°C Stir and heat for 2 hours, add 1,2-dichloroethane solution (0.3mol), heat the solution and stir at 100-110°C for 3 hours, then add methanol (150mL) and heat the solution, stir for 1 hour , and then cooled. This solution was added to a stirred mixture of silica gel (200 g, 60-200 μm, 100-140 Å) and toluene (400 mL), the mixture was stirred and refluxed for 6 h, cooled and the solid filtered, washed with ethanol (3×400 mL) by centrifugation and After drying, the compound represented by structural formula III is obtained, wherein m is 3, p is 2, a, b and c all exist, and d and e are both zero.

[0043] Prepare the modified functionalized silica gel material shown in structural formula I: Take 100g of the compound shown in the above structural formula ...

Embodiment 2

[0046] Preparation of polyfunctional cross-linked amino-functionalized silica gel shown in structural formula III: a solution of 3-chloropropylthiopropyltrimethoxysilane (0.8mol) and tetraethylenepentamine (1.6mol) was heated to 70°C Stir and heat for 2 hours, add a solution of 1,2-dichloroethane (1.6mol) and tetraethylenepentamine (0.4mol), heat the solution and stir at 100-110°C for 3 hours, add methanol (150 mL) and heated, stirred for 1 hour, then cooled. This solution and 3-mercaptopropyltrimethoxysilane (0.1 mol) were added to a stirred mixture of silica gel (700 g, 200-500 μm, 100-140 Å) and toluene (1.4 L), and the mixture was stirred and refluxed for 6 hours, Cool and filter the solid, wash with deionized water (3×1.6L) and dry to obtain the compound shown in the structural formula III, wherein m is 3, p is 4, W is 3-mercaptopropyl, a, b, c and e both exist and d is 0.

[0047] Prepare the modified functionalized silica gel material shown in structural formula I: Ta...

Embodiment 3

[0050] Preparation of polyfunctional cross-linked amino-functionalized silica gel shown in structural formula III: a solution of 3-chloropropylthiopropyltrimethoxysilane (1mol) and non-ethylene decaamine (1.8mol) was heated to 70°C and Stir and heat for 2 hours, add a solution of 1,2-dichloroethane (2.4mol) and non-ethylene decaamine (0.2mol), then heat and stir at 100-110°C for 5 hours, add methanol (450mL ) and the solution was heated, stirred for 1 hour, then cooled. This solution was added to a stirred mixture of silica gel (600 g, 200-500 μm, 100-140 Å) and toluene (1.2 L) along with 3-mercaptopropyltrimethoxysilane (0.1 mol) and hexyltrimethoxysilane (0.06 mol) , the mixture was stirred and refluxed for 6 hours, cooled and filtered the solid, washed with deionized water (3×1.6 L) and dried to obtain the compound shown in the structural formula III, wherein m is 3, p is 9, and W is 3 - mercaptopropyl, V is hexyl, a, b, c, d and e are all present.

[0051] Prepare the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com