Process for producing a fiber-reinforced thermoplastic resin molded product and product thereby produced

A thermoplastic resin and thermoplastic resin film technology, which is applied in the field of manufacturing fiber-reinforced thermoplastic resin molded products, can solve the problems of poor productivity and economical efficiency, and achieve the effects of reducing thermal aging, excellent removability, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A single glass fiber strand obtained by bundling 600 monofilaments with an average diameter of 13 micrometers was added to acid-modified molten polypropylene (260° C.) with an M1 (melt index) of 40 for melt impregnation, followed by , pultruded from a spinneret hole with an inner diameter of 0.53 mm at a rate of 50 m / min, and cut into a length of 20 mm with a granulator to obtain a fiber-reinforced thermoplastic resin substrate. The substrate had an average diameter of 0.53mm, an L / D of 37.7, a glass content of 45.5% by volume, and a resin impregnation rate of 100% (the average number of times n=5, where n is the number of measurements).

[0097] The above-mentioned glass content was obtained by heating the obtained fiber-reinforced thermoplastic resin substrate in an electric furnace at 600°C to burn off the resin, and then, the glass content (% by weight) was calculated from the remaining glass weight, and the value was converted into volume %, according to the specif...

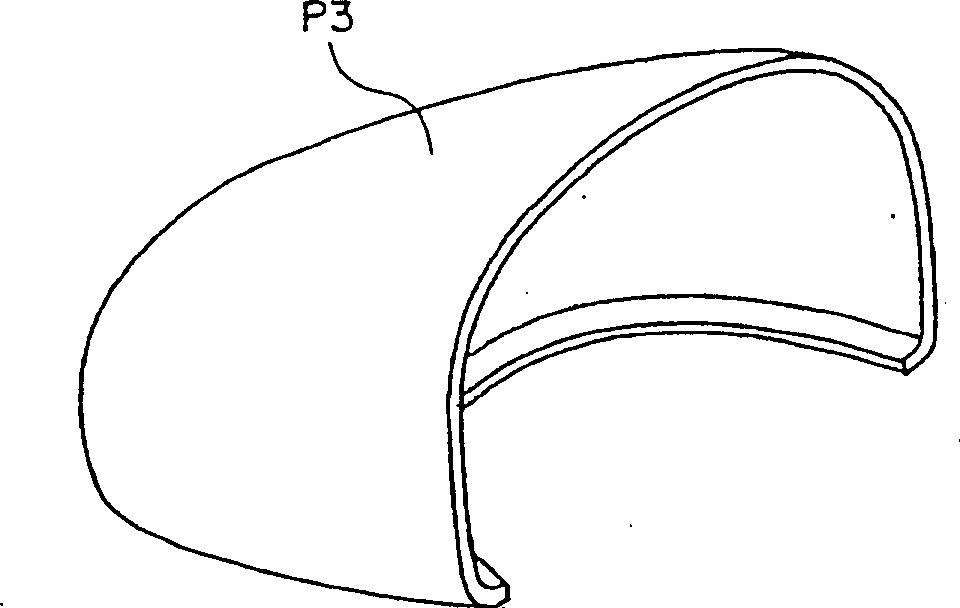

Embodiment 2

[0102] A safety shoe toe core as a molded article was produced in the same manner as in Example 1 except that the L / D of the fiber-reinforced thermoplastic resin base material was 56.6 (cut length: 30 mm). The length of the remaining filaments in the molten mass can maintain 100% of the initial length of the filaments in the substrate. The length of the remaining filaments in the toe core of the safety shoes keeps 95% of the initial length of the filaments in the base material.

Embodiment 3

[0104] A safety shoe toe tip core was made in the same manner as in Example 1, except that an average diameter of 0.70 mm, a glass content of 32.2% by volume, and an L / D of 28.6 (cut length: 20 mm) were used Fiber-reinforced thermoplastic resin substrates. The length of the remaining filaments in the molten mass can maintain 100% of the initial length of the filaments in the substrate. The length of the remaining filaments in the toe tip core of the safety shoes keeps 97% of the initial length of the filaments in the base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com