Easily polymerizable compound-treating apparatus using chamfered pot Flamge

A treatment device and a technology for connecting flanges, applied in chemical/physical processes, separation/purification of carboxylic acid compounds, chemical/physical/physicochemical processes, etc., can solve problems such as inability to measure liquid level and internal pressure state, blockage, etc. , to achieve the effect of preventing deterioration of production efficiency and reducing cleaning operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

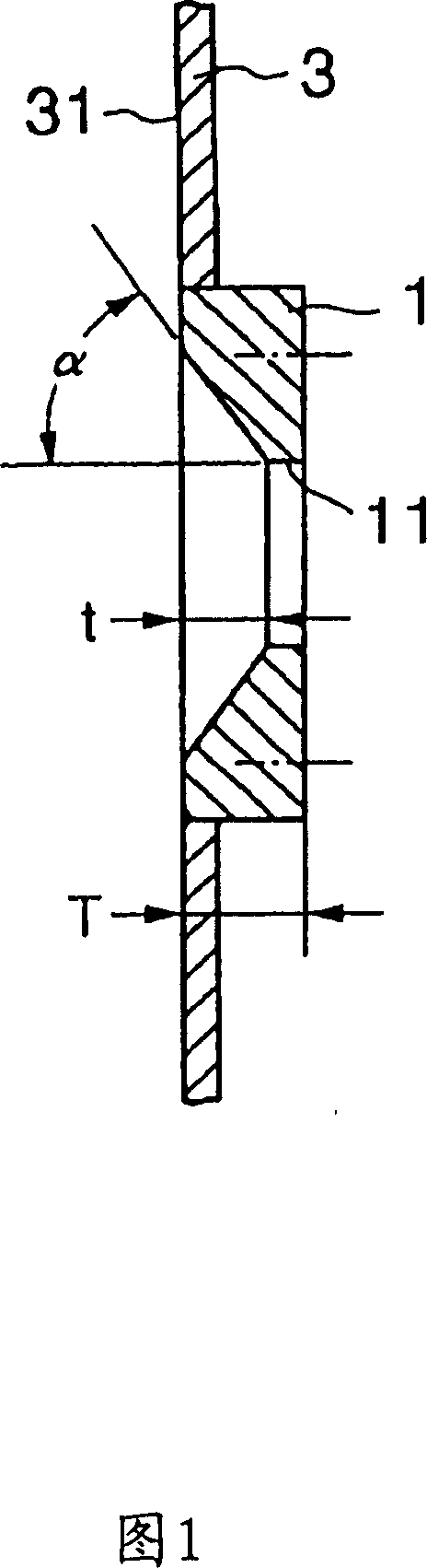

[0025] The chamfered butt joint flange shown in Figure 1 is used, and the butt joint flange is chamfered with a chamfer angle α=45° and a chamfer width t / total thickness T of the butt joint flange=70%. Machined counter flanges.

[0026] In the middle and lower positions of the main body wall of the stainless steel (SUS316) acrylic acid refining tower, the butt joint flange for the connection of the diaphragm pressure gauge is installed, and at the same time, the same butt joint for the connection of the liquid level gauge is installed. Flange, for acrylic refining.

[0027] The composition of the raw material is 99% by weight of acrylic acid, 1% by weight of heavy substances such as acrylic acid dimer, and continuously operated under the conditions of 2.5kPa at the top of the tower, a temperature of 52°C, a pressure of 5kPa at the bottom of the tower, a temperature of 73°C, and a reflux ratio of 1.0. moon. As a result of in-house testing after the operation was stopped, no p...

Embodiment 2

[0032] The chamfered butt joint flange shown in Figure 1 is used, the butt joint flange is chamfered with a chamfer angle α=35° and chamfer width t / total thickness of the butt joint flange T=50%. Machined counter flanges.

[0033] The butt flange is installed from the lower part of the acrylic acid refining tower made of stainless steel (SUS304) to the main body walls of the first and third stages, and is used as a window connection to purify acrylic acid.

[0034] The raw material composition is 95% by weight of acrylic acid, 5% by weight of light polymers such as acetic acid, and is continuously operated for 6 months under the conditions of 10kPa top pressure and 50°C temperature, 18kPa bottom pressure and 83°C temperature.

[0035] During this period, there is no polymer attached to the window, and the state inside the tower can be observed well. As a result of in-house testing, no polymer adhesion was found on any of the mating flanges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com