Method and apparatus for producing thick oil based on sound, light and electricity combination function

A combined action, heavy oil technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of cumbersome operation process, high maintenance cost, complicated process, etc. The effect of superior oil quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for extracting heavy oil based on the combination of sound, light and electricity, the steps are as follows:

[0029] 1). Frequency selection: Collect heavy oil samples from oil wells and divide them evenly into 10 parts. Divide the frequency range of ultrasonic waves from 20KHz to 400KHz into corresponding 10 frequency bands. Then, under the same sound intensity and time, use each frequency band to correspond to one part. Thick oil is used for action, and then the physical properties of the oil sample after action are analyzed, such as viscosity and thermal effect, and its composition change is analyzed by gas chromatography, and its comprehensive value is finally evaluated. The frequency band with obvious thermal effect and viscosity reduction is the main frequency range. Determine the range of its main frequency;

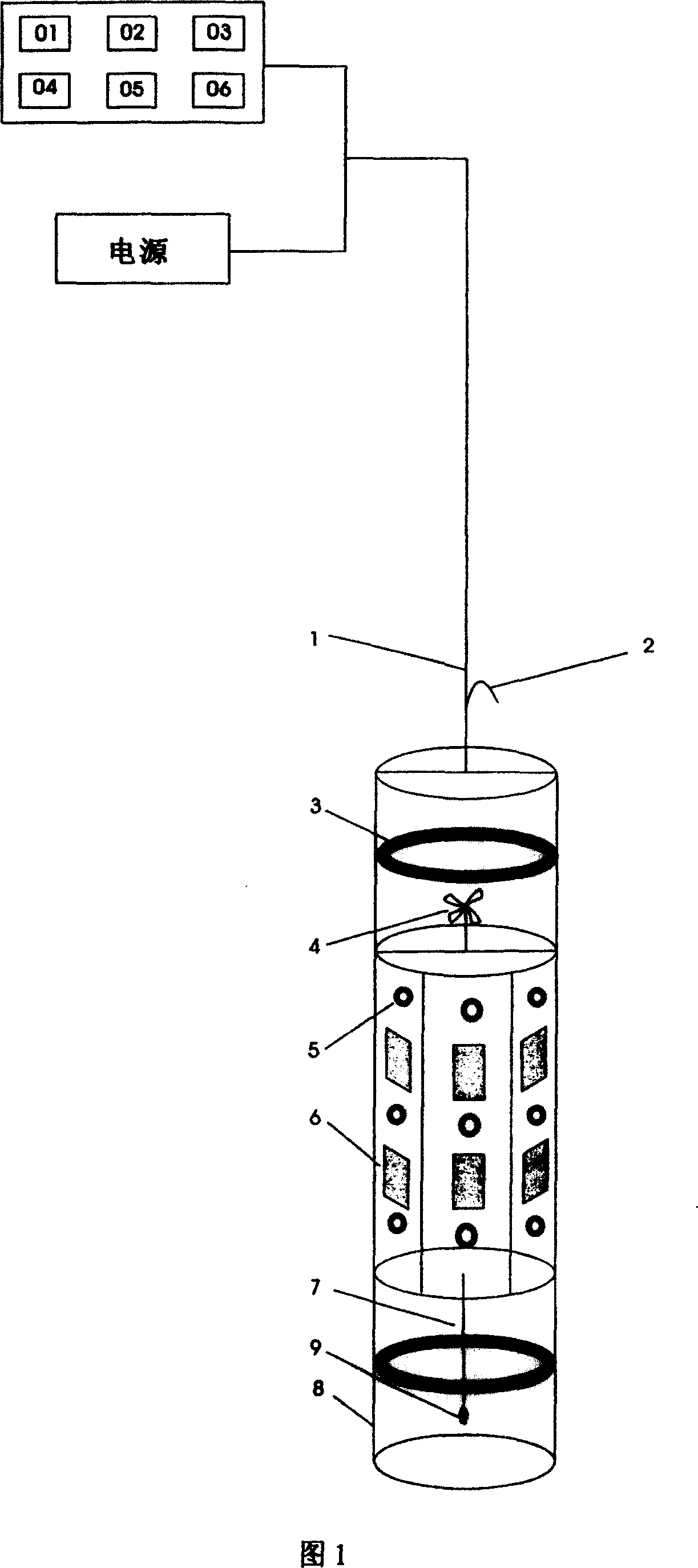

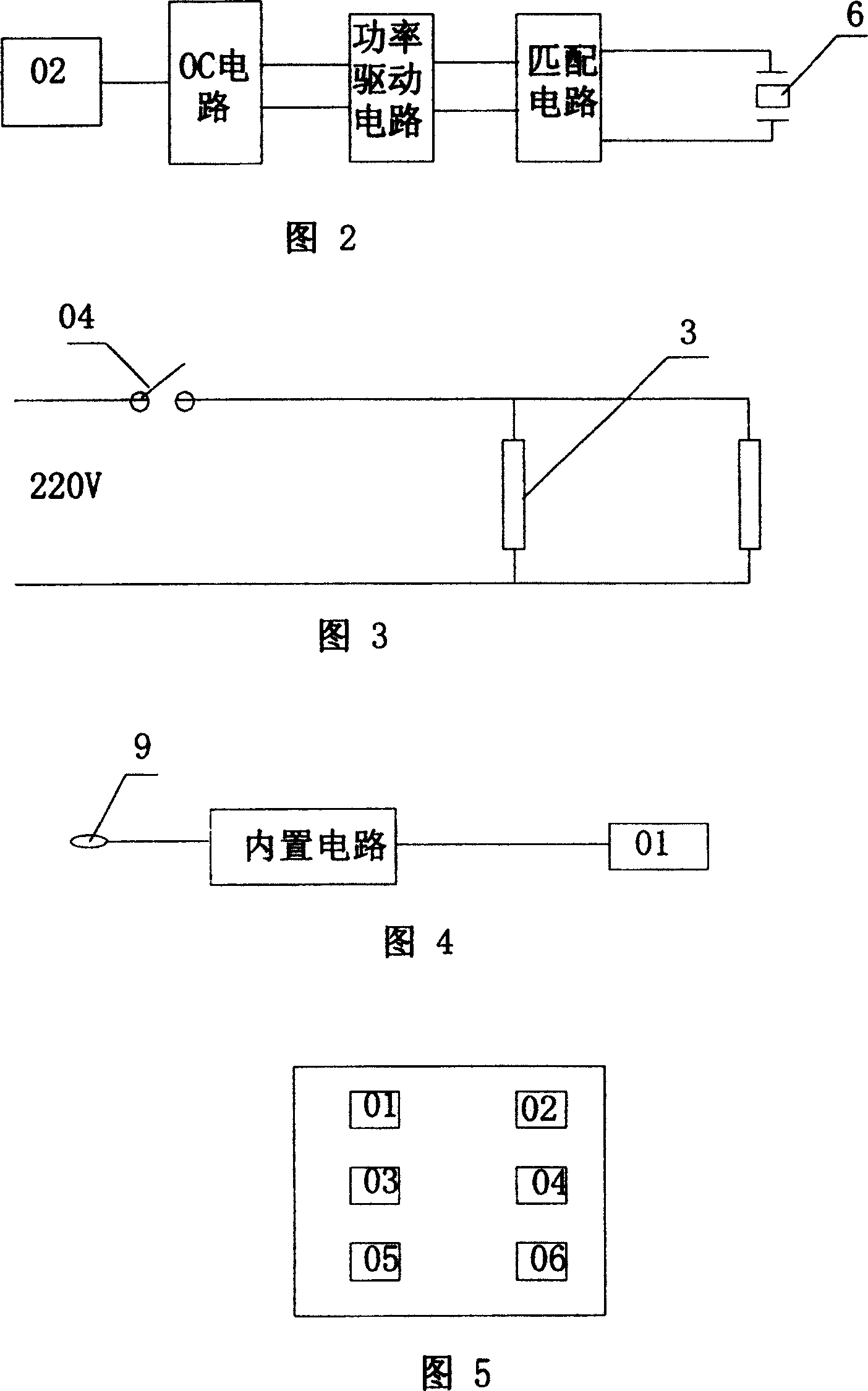

[0030]2). Installation device: as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the device is divided into two parts: the downhole part and...

Embodiment 2

[0037] A method for extracting heavy oil based on the combination of sound, light and electricity, the steps are as follows:

[0038] 1). Frequency selection: collect heavy oil samples from oil wells, divide them evenly into 20 parts, and divide the frequency of ultrasonic waves from 20KHz to 400KHz into corresponding 20 frequency bands, and then, under the same sound intensity and time, use each frequency band to correspond to one part Thick oil is used for action, and then the physical properties of the oil sample after action are analyzed, such as viscosity and thermal effect, and its composition change is analyzed by gas chromatography, and its comprehensive value is finally evaluated. The frequency band with obvious thermal effect and viscosity reduction is the main frequency range. Determine the range of its main frequency;

[0039] Preliminary test, using ultrasound in a certain frequency range from 20KHz to 400KHz to act on a certain heavy oil sample, the viscosity red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com