Driver of combined part swing engine

A transmission and engine technology, applied in the direction of wheel transmission, transmission control, chain/belt transmission, etc., can solve the problems of large noise, large vibration of driven shaft 125, large space occupied by driven shaft 125, etc. , to achieve the effect of reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

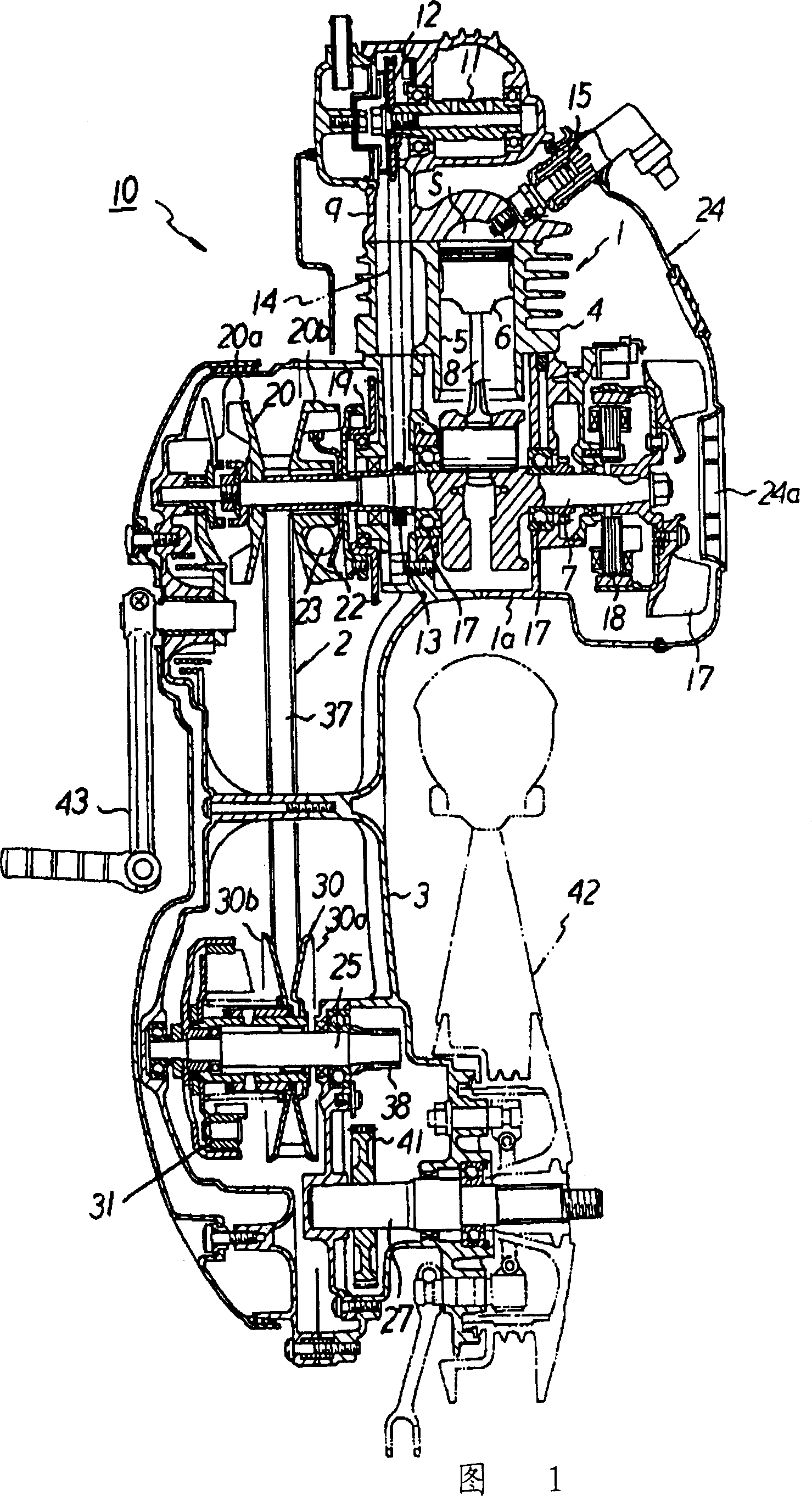

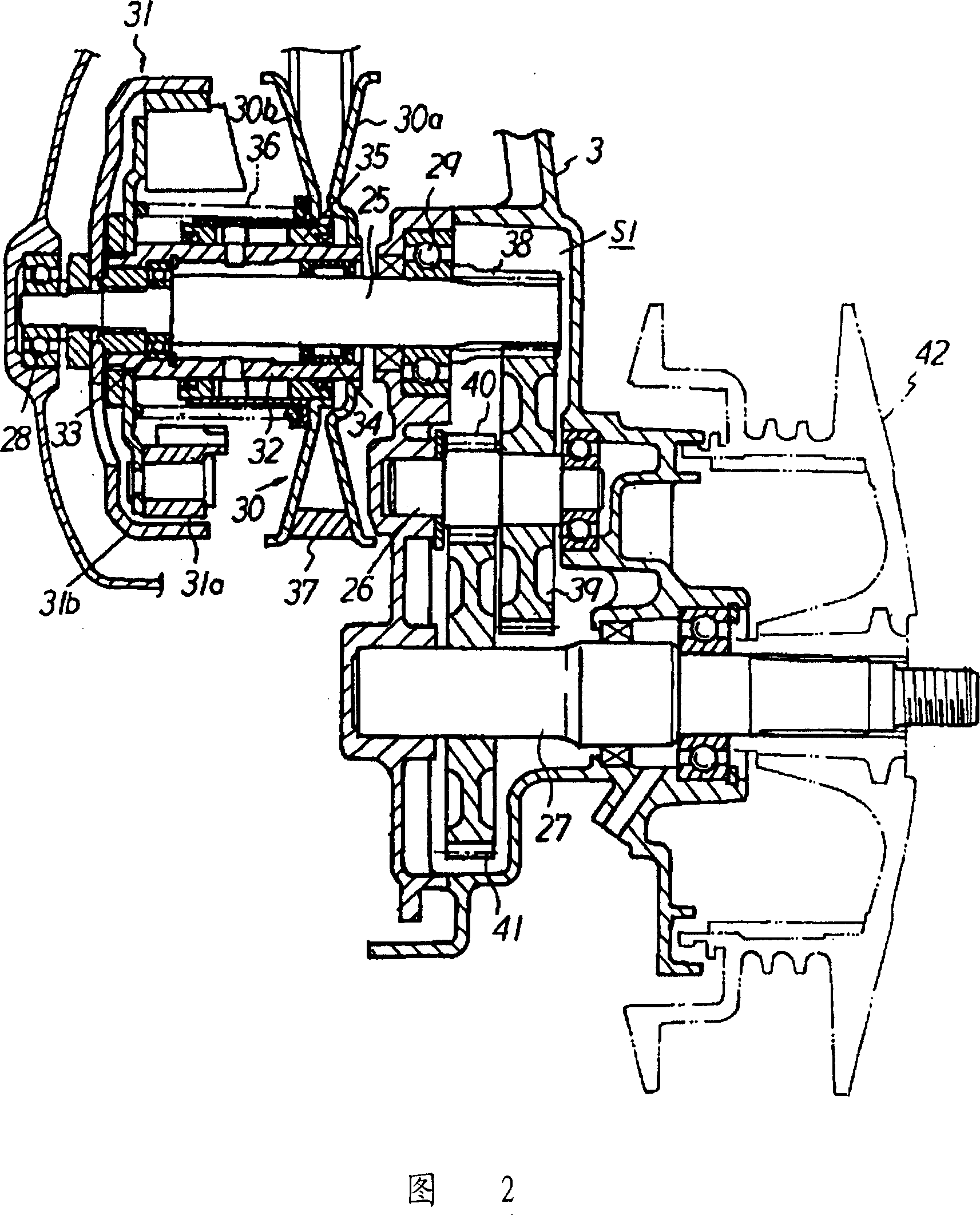

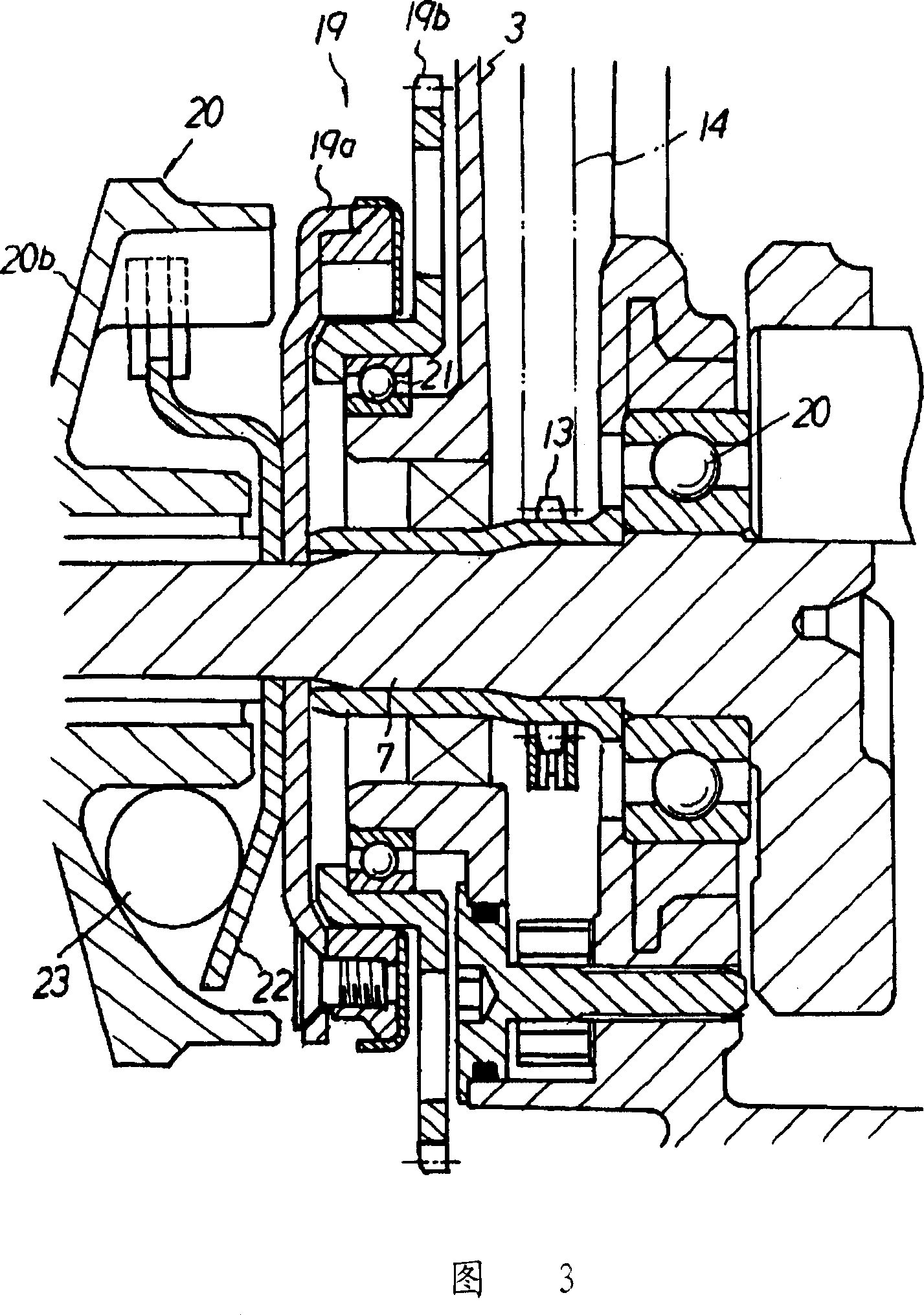

[0020] Fig. 1 is a transverse sectional view of an assembly swing engine, Fig. 2 is a partial transverse section view of an assembly swing engine showing the structure of the transmission device of the present invention, and Fig. 3 is a partial transverse section of a one-way clutch of an assembly swing engine picture.

[0021] Assembled swing type engine 10 shown in Fig. 1 is the engine that is contained on the small motorcycle type automatic two-wheel vehicle that is not shown in the figure, and it is the forced air-cooled 4 stroke engine (hereinafter referred to as engine) 1, and comprises V-shaped belt The automatic transmission device 2 and the transmission device of the deceleration device are compactly assembled as an assembly and constituted, wherein the automatic transmission device is arranged on the side extending from the left side of the crankcase 1a of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com