Vehicle-mounted metallic halide discharge lamp

A technology of metal halides and discharge lamps, which is applied to the components of gas discharge lamps, electric light sources, lighting devices, etc., and can solve problems such as loss, weak penetration through fog, and limited ability to penetrate fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

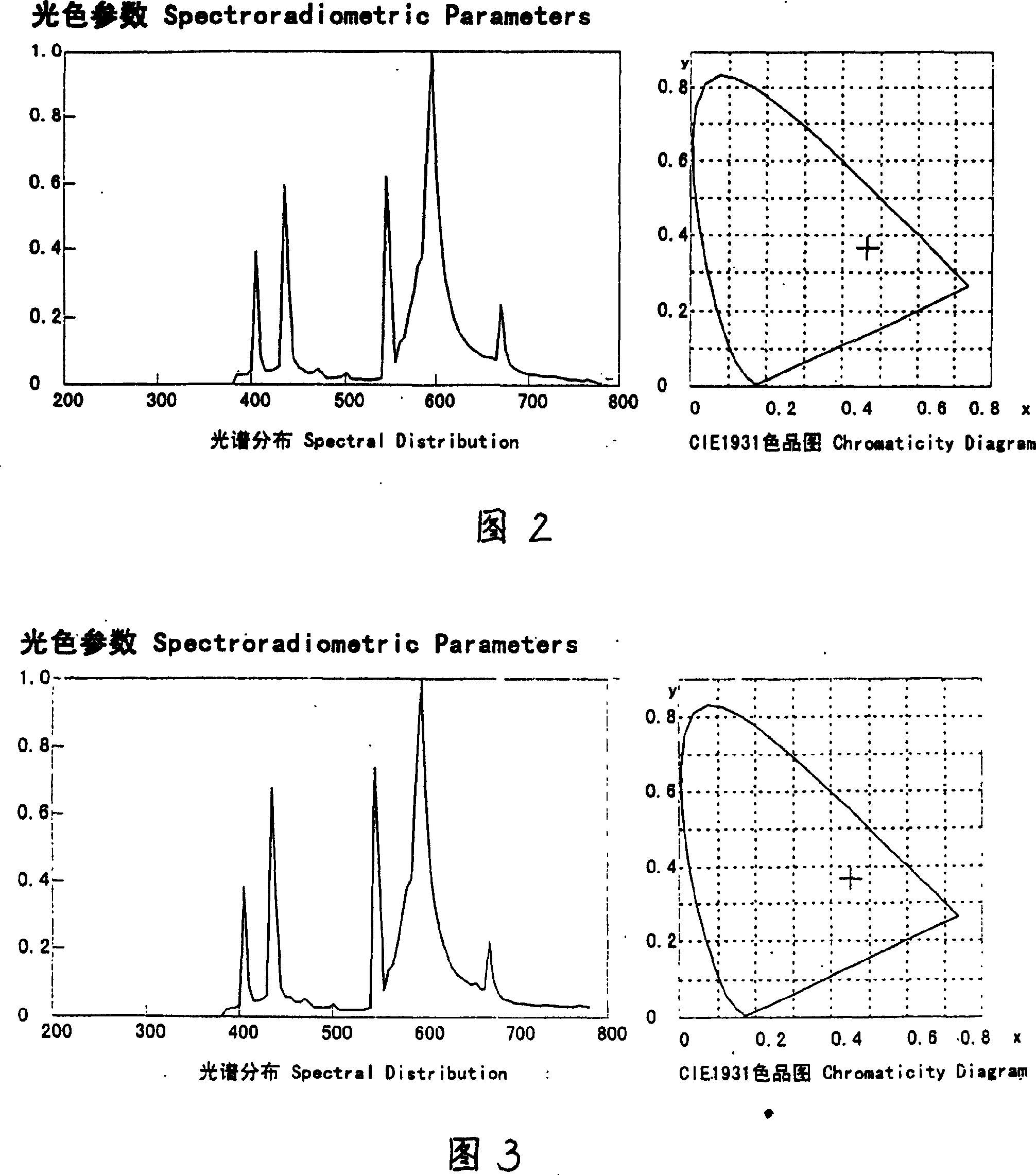

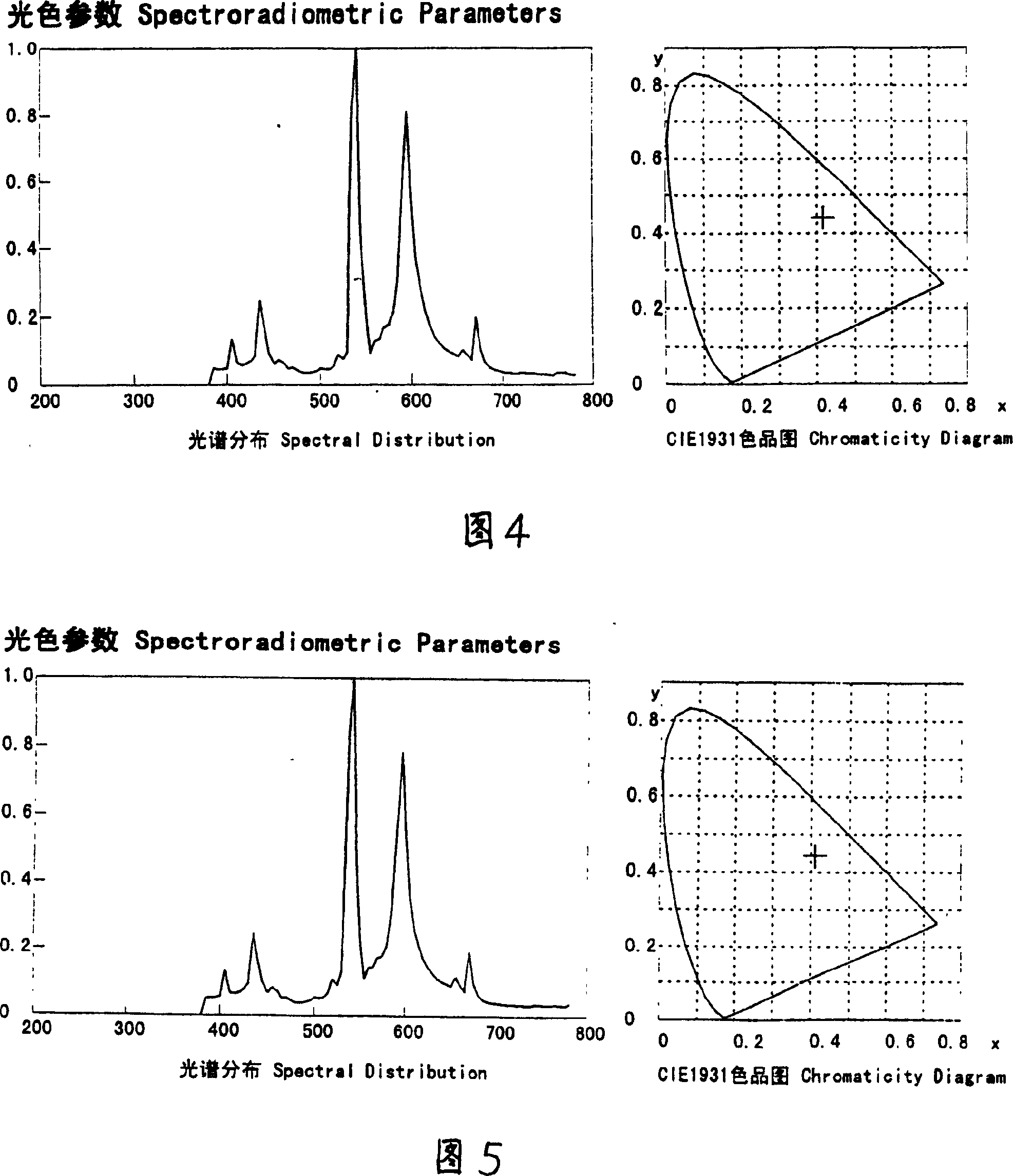

Embodiment 1

[0015] The first discharge lamp of the present invention is filled with 8 atmospheres of xenon and 6.6mg / cm 3 The volume of mercury vapor is 60mm 3 The 35W discharge tube is filled with 4.1mg / cm 3 Sodium iodide, the light color point of this lamp is at the chromaticity point (x, y)=(0.4781, 0.3562) on the CIE1931 chromaticity diagram. , The luminous flux of the green light (520~610nm) part reaches more than 2500 lumens, and the spectrum and chromaticity diagrams are listed in Figure 2.

Embodiment 2

[0017] The second discharge lamp of the present invention has a volume of 80mm 3 In the 50W discharge tube, the ratio of mercury and sodium halide is adjusted, and xenon gas of 8 atmospheres, 12.5mg / cm 3 of mercury vapor and 6.25mg / cm 3 Sodium bromide, the luminosity point (x, y)=(0.4507, 0.3553) of this lamp, its light color is less than the orange part of the first lamp, close to golden yellow, and the luminous flux of the yellow-green light (520~610nm) part is greater than 2400 lumens, the spectrum and chromaticity diagrams are listed in Figure 3.

Embodiment 3

[0019] The third discharge lamp of the present invention, in 60mm 3 The volume of the 35W discharge lamp is filled with 8 atmospheres of xenon, 8.3mg / cm 3 mercury vapor, filled with a certain amount of sodium iodide and a certain amount of thallium iodide (weight ratio sodium iodide:thallium iodide=3:1), the total concentration of sodium iodide and thallium iodide is 4.16mg / cm 3 , the light color point of this lamp is on the CIE1931 chromaticity diagram, the chromaticity point (x, y) = (0.4161, 0.4415), its light color is normal yellow, and the proportion of 535 green light is slightly greater than 585 orange yellow, which is The luminous flux of the two parts is greater than 2700 lumens, and its spectrum diagram and chromaticity diagram are listed in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com