Printing veneering sheet material and its manufacturing method and use

A veneer and printing technology, applied in the field of decorative materials, can solve the problems of complex processing, long processing time, waste of aluminum materials, etc., and achieve the effect of simple process, good effect and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

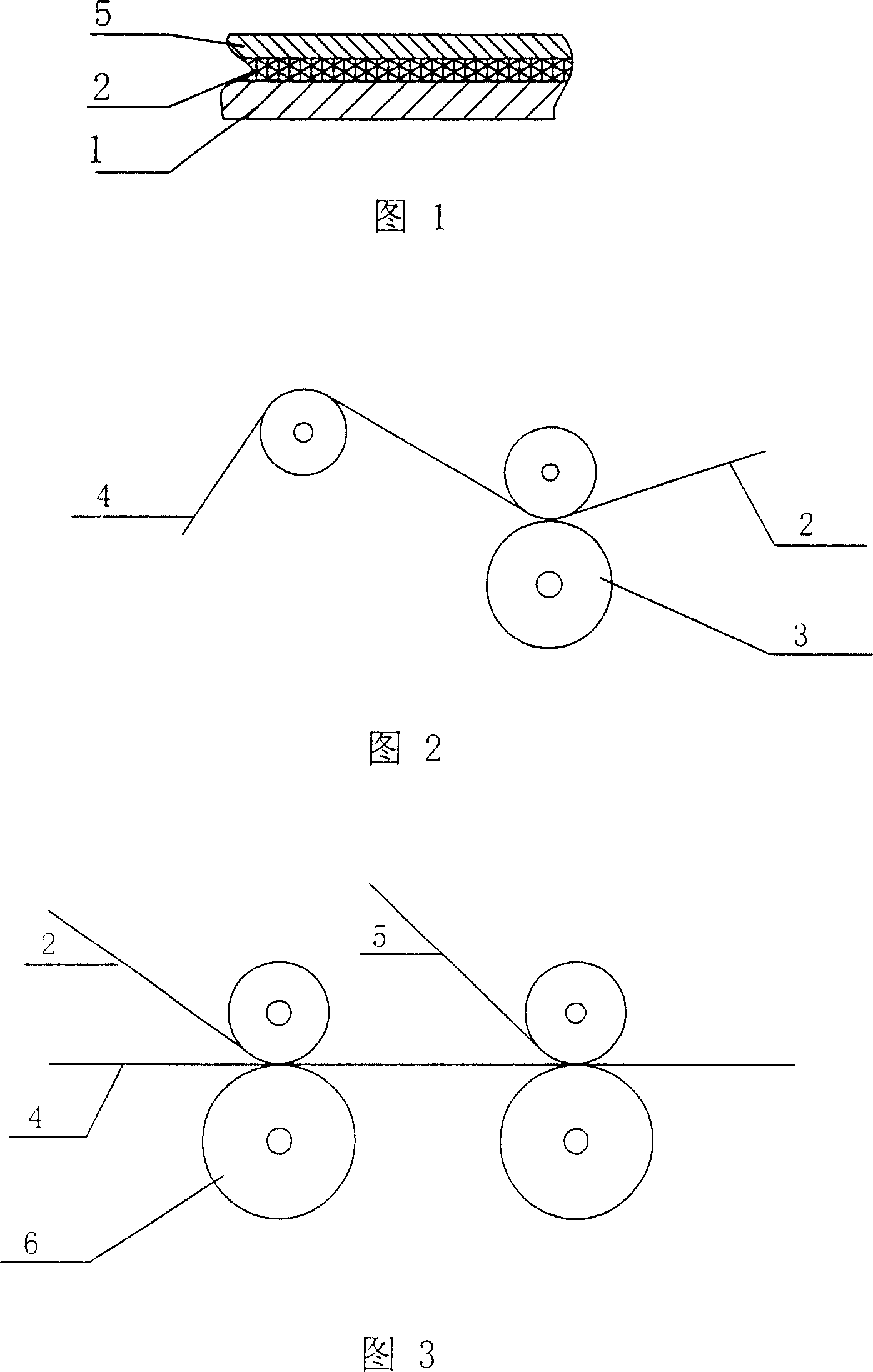

[0030] The specific embodiment 1 of the present invention is made up of metal thin layer 1 and decorative thin layer 2, and metal thin layer 1 is aluminum sheet, and decorative thin layer 2 is the PET film with imitation stone pattern, and decorative thin layer 2 is close to the surface of aluminum sheet superior. A layer of removable protective film 5 is pasted on the surface of the PET film; the protective film 5 can be torn off after the construction is completed, so as to avoid damaging the surface of the product during handling.

Embodiment 1

[0031] The manufacture method of specific embodiment 1 of the present invention is as follows:

[0032] 1) Prepare the decorative thin layer material 4, that is, prepare the PET film, and use the gravure printing machine 3 to print the imitation stone pattern on the PET film to form the decorative thin layer 2;

[0033] 2) Coat a layer of hot melt adhesive or high-strength glue on the PET film with the pattern printed with a common coating machine;

[0034] 3) Prepare the aluminum sheet, first flatten and clean the aluminum sheet, and use a common compound machine 6 to compound the decorative thin layer with the aluminum sheet; then, use a common compound machine 6 to compound a layer on the PET film and remove it Protective film, you can get the finished product.

Embodiment 2

[0036] The manufacture method of specific embodiment 2 of the present invention is as follows:

[0037] 1) Prepare the decorative thin layer material 4, that is, prepare the BOPP film, and use the gravure printing machine 3 to print imitation wood patterns on the BOPP film to form the decorative thin layer;

[0038] 2) Coat a layer of hot melt adhesive or high-strength glue on the printed BOPP film with a common coating machine;

[0039] 3) Prepare the aluminum foil, first flatten and clean the aluminum foil, and use the common compound machine 6 to compound the decorative thin layer with the aluminum foil; then, use the common compound machine 6 to compound a layer of removable protective film on the BOPP film, You can get the finished product.

[0040] The characteristics of the specific embodiment 3 of the present invention are: the metal thin layer 1 is a stainless steel sheet, and the material used for the decorative thin layer 2 is a BOPP film with a natural scene patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com