System and method for growth of lithium niobate crystal with rough chemical ratio by melt injection process

An implantation method, lithium niobate technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult to grow large crystals, complicated equipment, high defect density, and achieve the advantages of industrial production and crystal composition. The effect of small fluctuation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

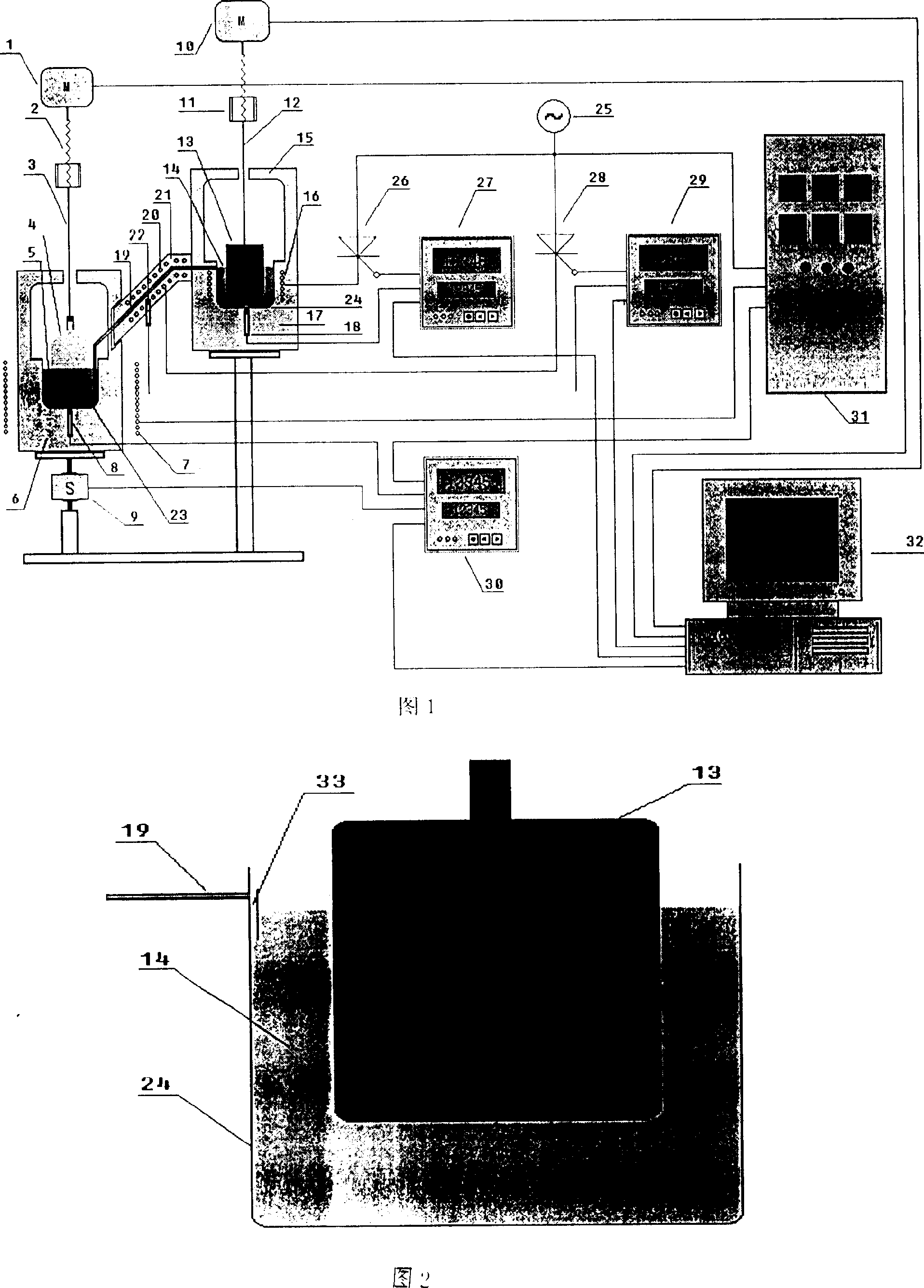

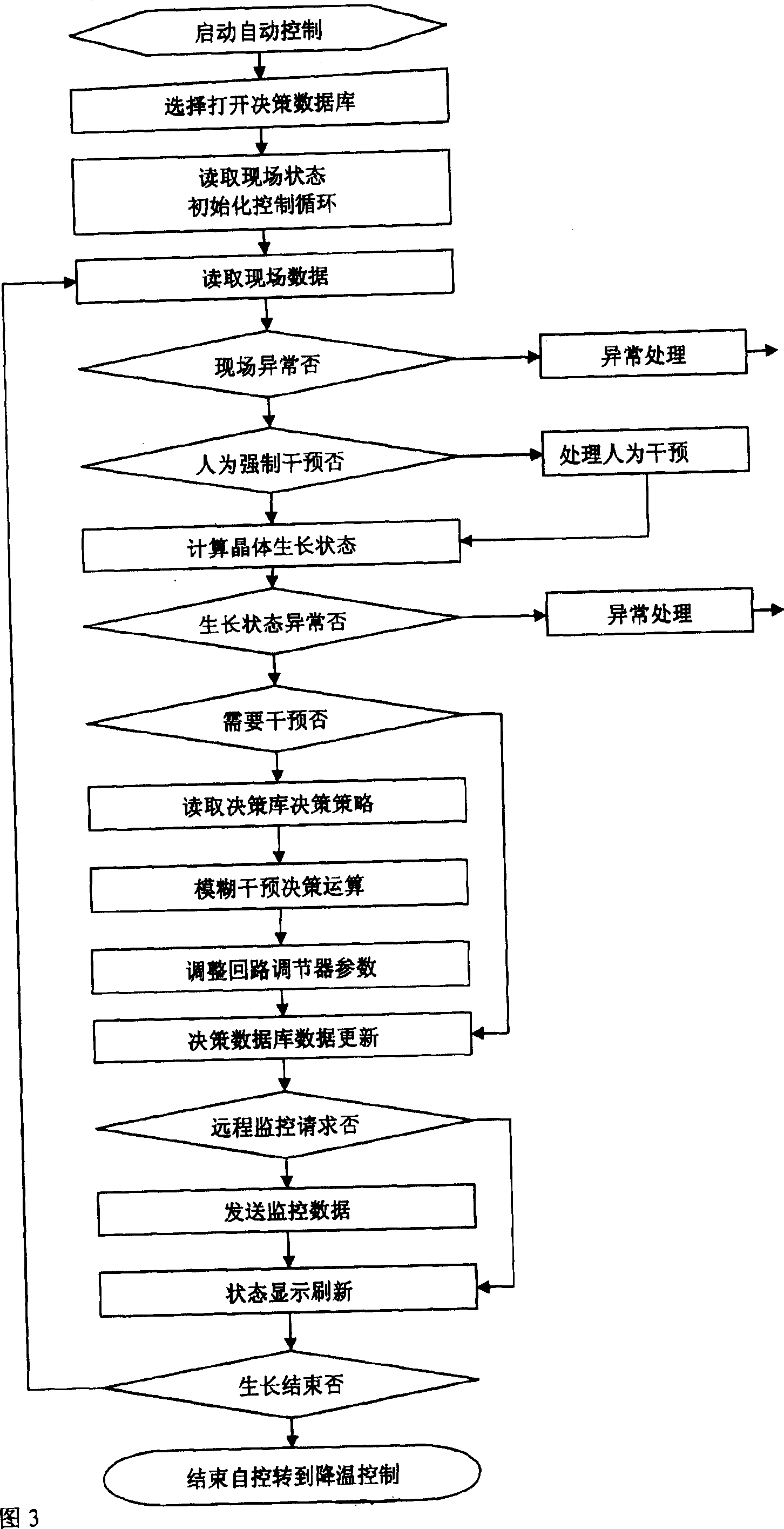

[0032] As shown in Figure 1: This melt injection method grows near-chemical ratio lithium niobate crystal system, the system includes a crystal growth furnace, a feeding furnace, 2 thyristor controllers, 3 loop regulators, and an intermediate frequency power supply 31 , industrial control computer (32) and supporting software 7 parts:

[0033] The crystal growth furnace part includes a motor 1, which drives the lower screw 2 and the seed rod 3 to form a pulling system for crystal growth. The seed rod pulls the crystal 4 from the melt 5 in the crucible 23. Below the crucible is a thermocouple 8. It is in the insulation material 6 outside the crucible, and the periphery of the crucible is the induction coil 7 for heating, the induction coil 7 is connected to the intermediate frequency power supply, and the force sensor 9 is under the insulation materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com