A kind of preparation method of gold-boron alloy target material

A gold-boron alloy target technology, which is applied in the field of gold-boron alloy target preparation, can solve the problems of peeling, unstable content, uneven target structure, etc., reduce the requirements of equipment and technology, and the preparation method is simple and easy , Film composition control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of gold-boron alloy target with 20% boron atom content:

[0023] Step 1. Mix gold powder and boron powder evenly, and then press on a hydraulic press to obtain a powder compact; the atomic percentage of boron in the powder compact is 20%, and the balance is gold; the gold powder and boron powder None of the average particle diameters is greater than 50 μm, and none of the mass purity is less than 99.99%; the pressing pressure is 20 MPa, and the pressing time is 2 minutes;

[0024] Step 2. Using a non-consumable vacuum electric arc furnace, the powder compact described in step 1 is subjected to vacuum arc melting twice to obtain an ingot; during each arc melting process, the vacuum degree is controlled to be no greater than 5.0×10 -3 Pa;

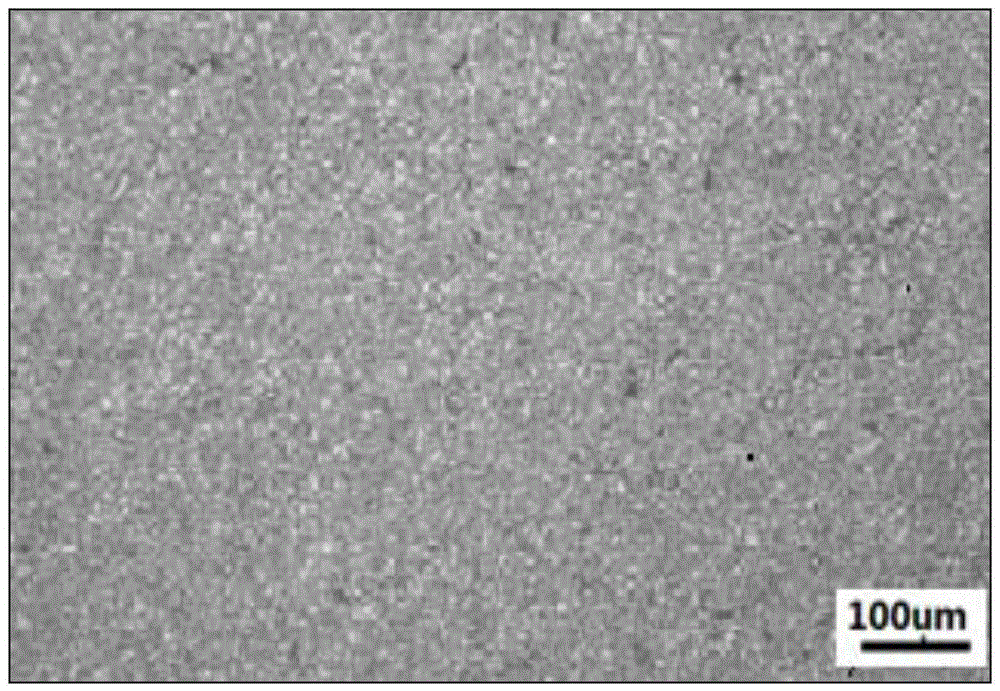

[0025] Step 3, breaking the ingot described in step 2, and then using a high-energy ball mill to high-energy ball mill the crushed ingot for 2 hours at a ball milling rate of 400 r / min to obtain gold-boron alloy powder wit...

Embodiment 2

[0029] Preparation of a gold-boron alloy target with a boron atom content of 40%:

[0030] Step 1. Mix gold powder and boron powder evenly, and then press on a hydraulic press to obtain a powder compact; the atomic percentage of boron in the powder compact is 40%, and the balance is gold; the gold powder and boron powder None of the average particle diameters is greater than 50 μm, and the mass purity is not less than 99.99%; the pressing pressure is 30 MPa, and the pressing time is 1 min;

[0031] Step 2. Using a non-consumable vacuum electric arc furnace, the powder compact described in step 1 is subjected to vacuum arc melting twice to obtain an ingot; during each arc melting process, the vacuum degree is controlled to be no greater than 5.0×10 -3 Pa;

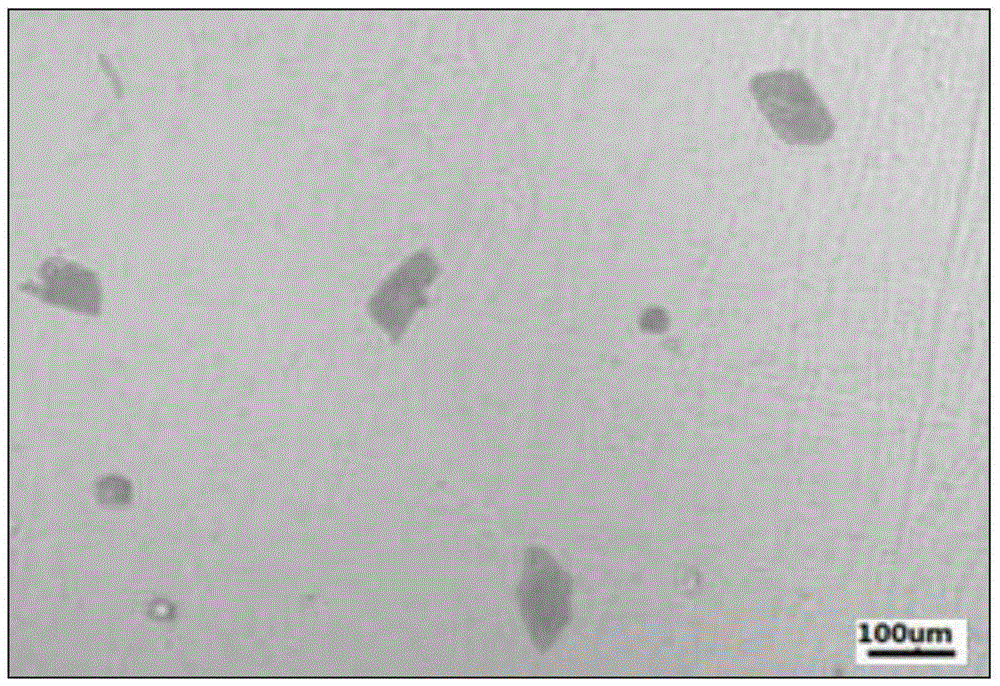

[0032] Step 3, breaking the ingot described in step 2, and then using a high-energy ball mill to high-energy ball mill the crushed ingot for 2 hours at a ball milling rate of 400 r / min to obtain gold-boron alloy powder with...

Embodiment 3

[0036] Preparation of gold-boron alloy target with 60% boron atom content:

[0037] Step 1. Mix gold powder and boron powder evenly, and then press on a hydraulic press to obtain a powder compact; the atomic percentage of boron in the powder compact is 60%, and the balance is gold; the gold powder and boron powder None of the average particle diameters is greater than 50 μm, and the mass purity is not less than 99.99%; the pressing pressure is 25 MPa, and the pressing time is 2 minutes;

[0038] Step 2. Using a non-consumable vacuum electric arc furnace, the powder compact described in step 1 is subjected to vacuum arc melting twice to obtain an ingot; during each arc melting process, the vacuum degree is controlled to be no greater than 5.0×10 -3 Pa;

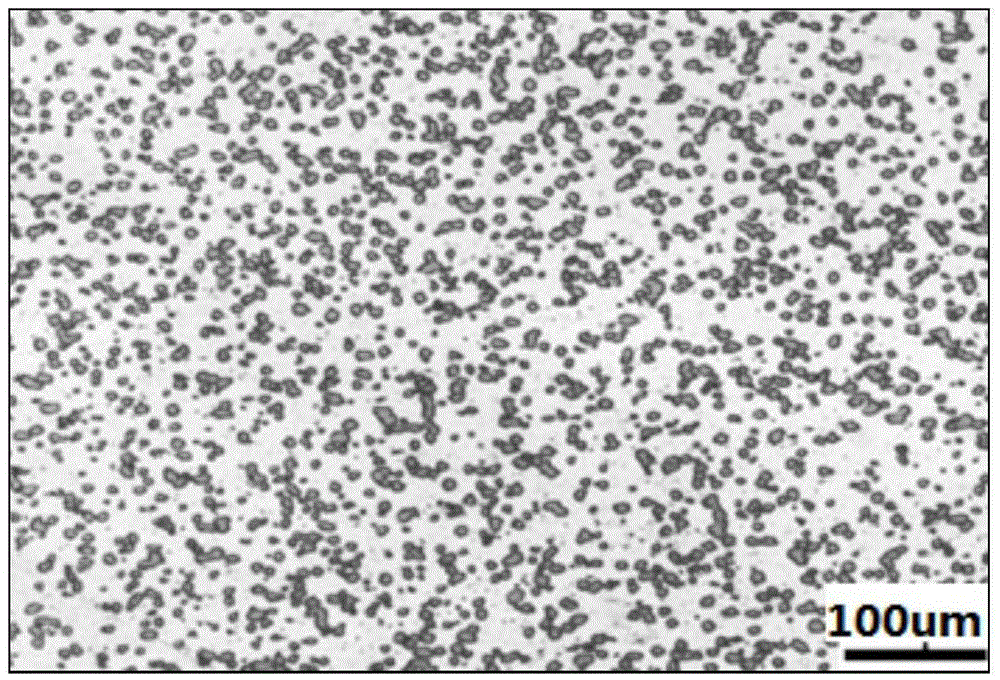

[0039] Step 3, breaking the ingot described in step 2, and then using a high-energy ball mill to high-energy ball mill the crushed ingot for 1.5 hours at a ball milling rate of 450r / min to obtain gold-boron alloy powder with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com