Byeing method spinning material using 3-indoxyl indigo blue and equipment utilizing said method

A kind of indoxyl, equipment technology, applied in the field of equipment using this method, can solve the problems of fashion ephemerality, etc., to achieve the effect of helping absorption and impregnation ability, eliminating fabric aging, and completely penetrating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

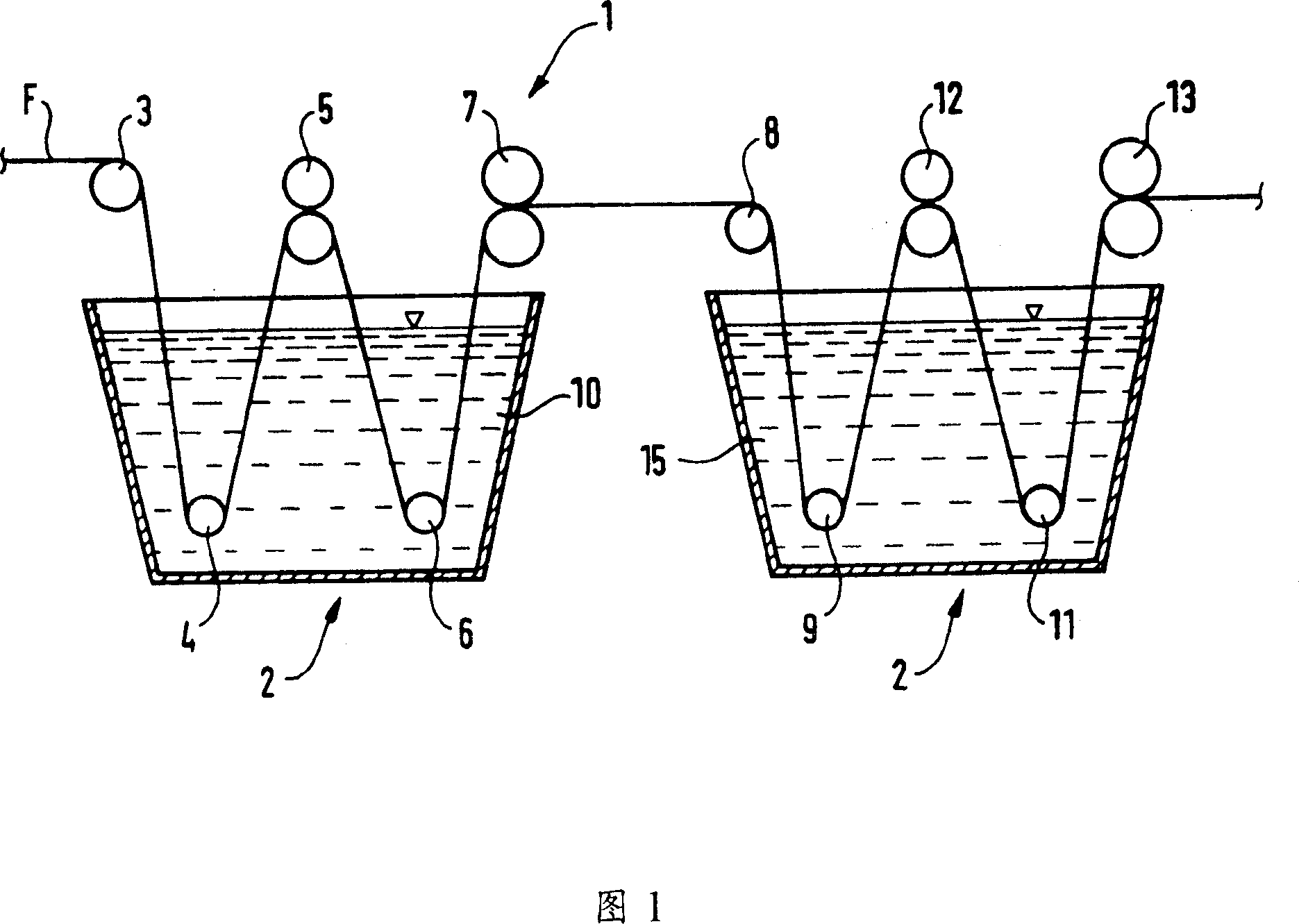

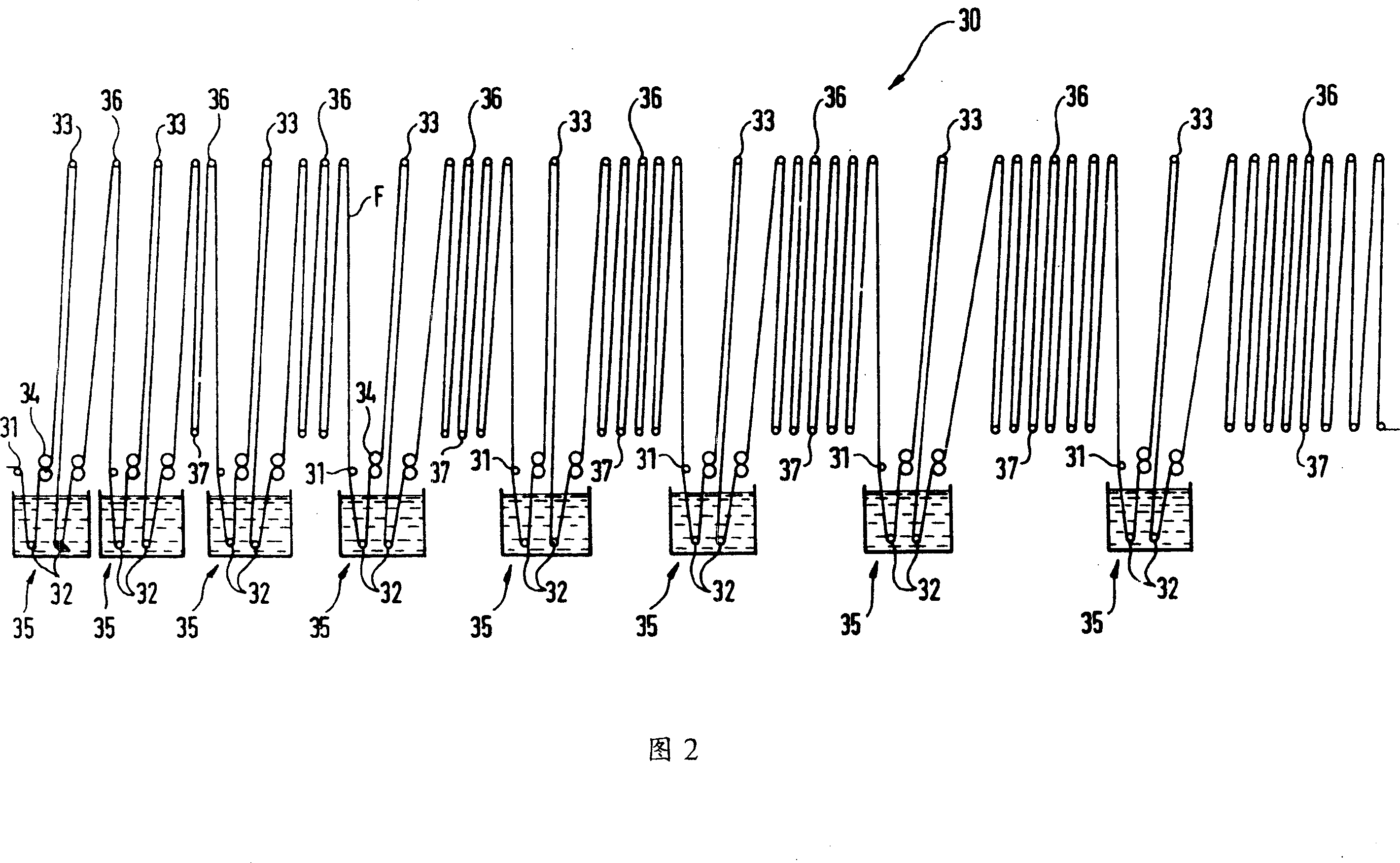

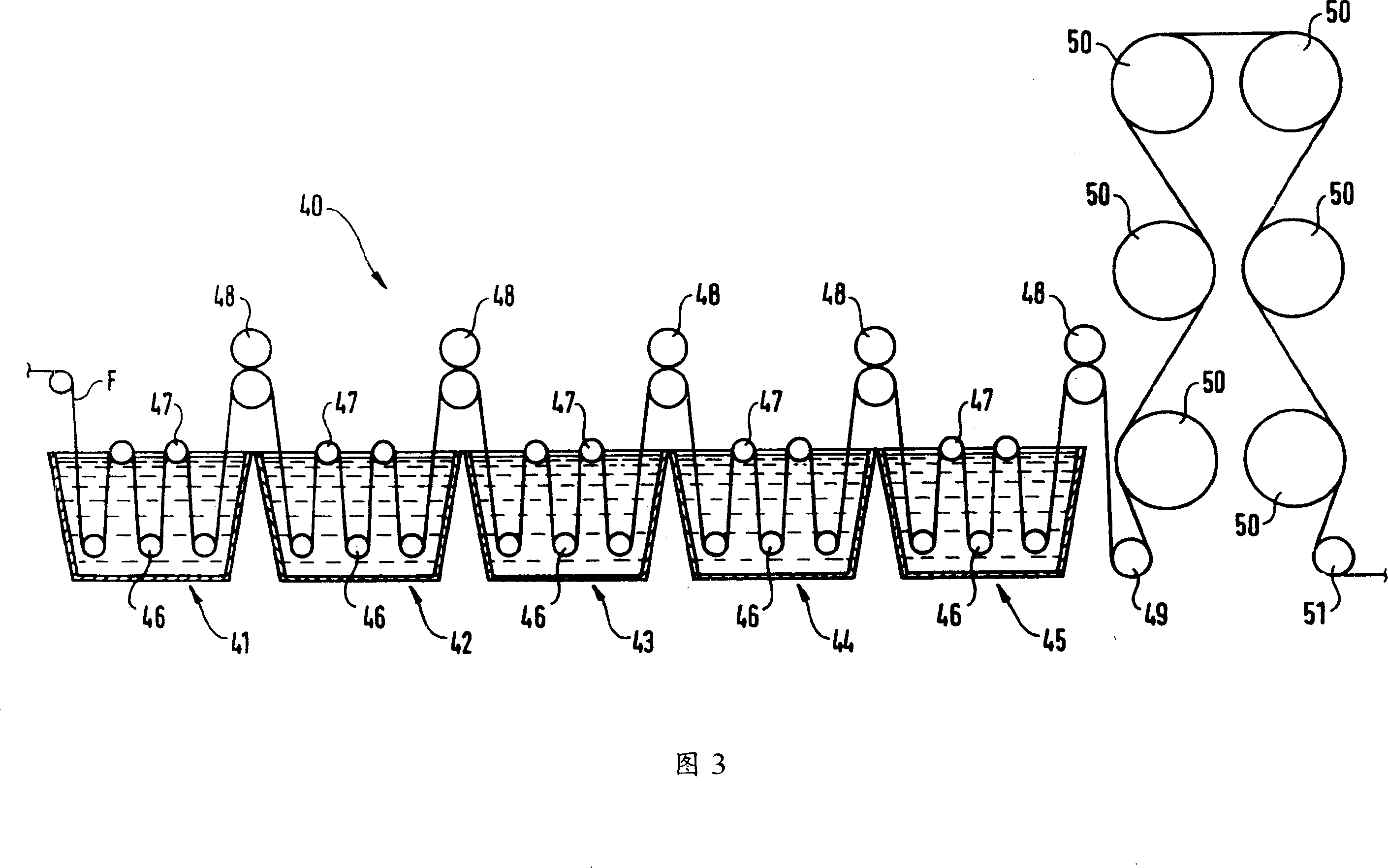

[0061]The method of the present invention will be described below with reference to FIGS. 1-5 in sequence. According to the method of the invention, first, the pre-washing stage is carried out by feeding the yarn F forward from the delivery roller, on which the yarn will pass through the pre-washing device 1, which includes two or several Liquid 10, 15 for tank 2. The yarn is led by rollers 3 and 4 into a first tank 2 containing a pre-wash liquor, then, on leaving this wash liquor, the yarn passes between two squeeze rollers to remove excess liquor and then passes through the rollers 6, the yarn is again immersed in the pre-wash solution. On leaving the bath, the yarn passes between two squeeze rollers 7 . Guided by guide rollers 8 and 9 , the yarn is then dipped into the prewash liquor 15 contained in the second tank 2 . The yarn is conveyed through the second groove by a sequence of operations between the two squeeze rollers 12, between the guide roller 11 and then betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com