Cap pneumatic picker of var fuel pot of ball bed high-temperature reactor air cooled

A high-temperature gas-cooled reactor and grabbing device technology, applied in the field of reactor engineering, can solve problems such as not allowing personnel to approach, complex equipment structure and operation, and large radiation dose, so as to achieve high equipment reliability, ensure neutrality, and improve The effect of accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

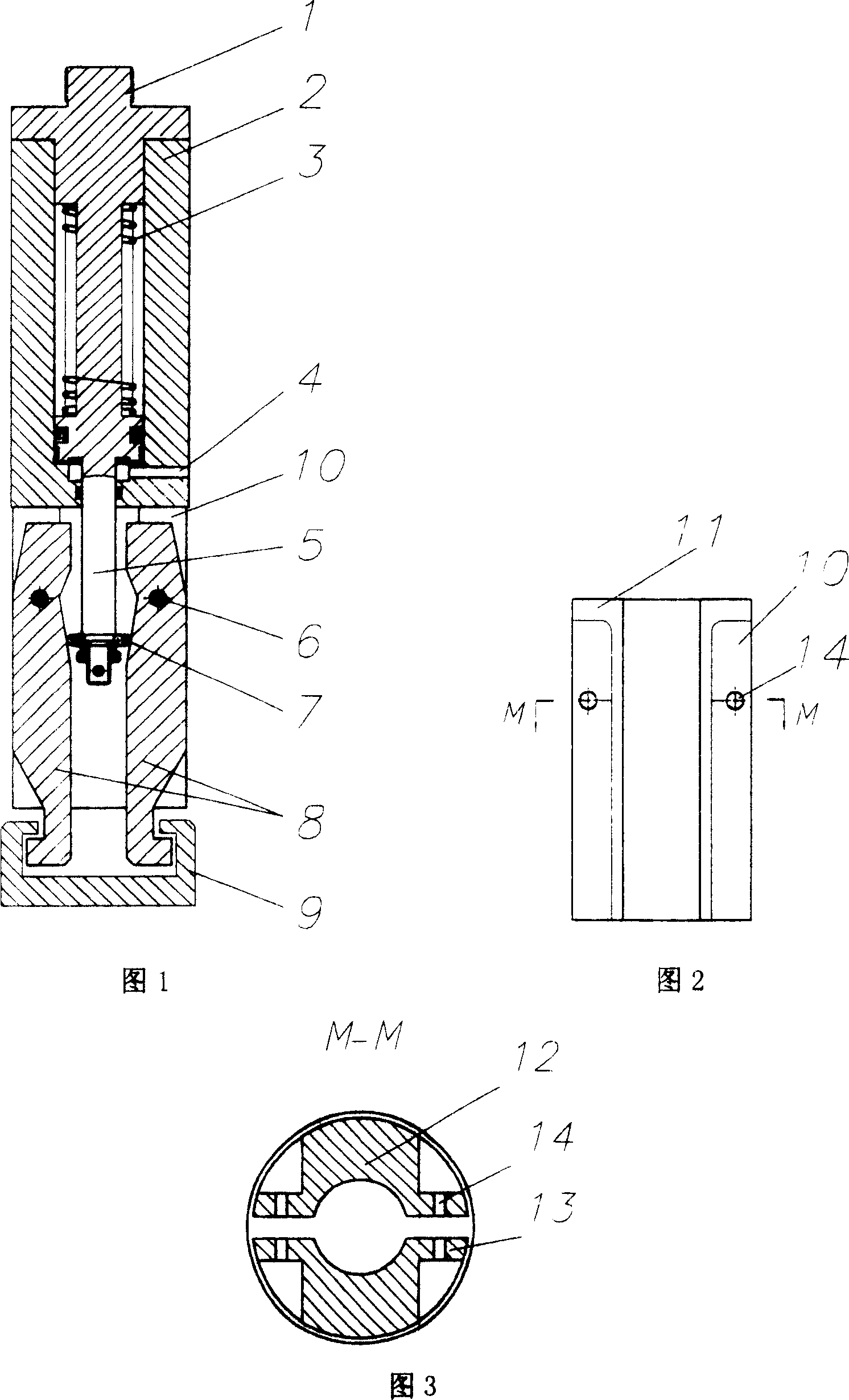

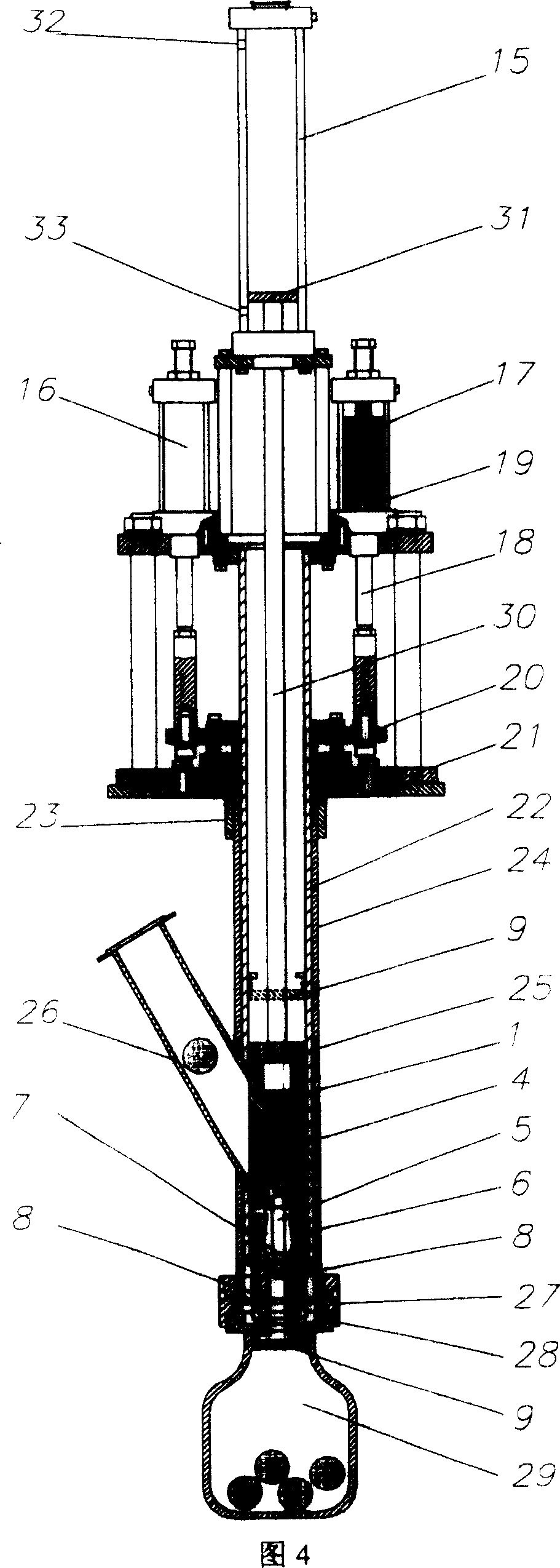

[0012] The structure of the pebble bed high temperature gas-cooled reactor spent fuel tank plug pneumatic grasping device proposed by the present invention is shown in Figure 1, including a piston 1, a piston barrel 2, a spring 3, a piston rod 5, a fixing member 10, and a pressure wheel 7 and jaw 8. The piston 1 is placed in the piston barrel 2, and the piston rod 5 is installed at the end of the piston 1. The upper end 11 of the fixing part 10 is circular, as shown in Figure 2, the fixing part 10 is relatively fixed with the piston cylinder 2 in the circular part 11, and the lower part of the fixing part 10 is a cross cylinder, and its cross-sectional view is shown in Figure 3, The piston rod 5 mounted on the end of the piston 1 stretches into the fixture. The claws 8 are symmetrically fixed on the thin end 13 of the cross cylindrical fixing member through the pins 6 , and a T-shaped channel is formed between the two claws 8 . The pressure roller 7 is installed on the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com