High-turbidity water treater with integrated flocculation, air floating and membrane separation functions

A water treatment device and membrane separation technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the frequent start and stop of power equipment and high pipeline pressure requirements , short backwash cycle and other issues, to achieve the effect of reducing the equipment footprint, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

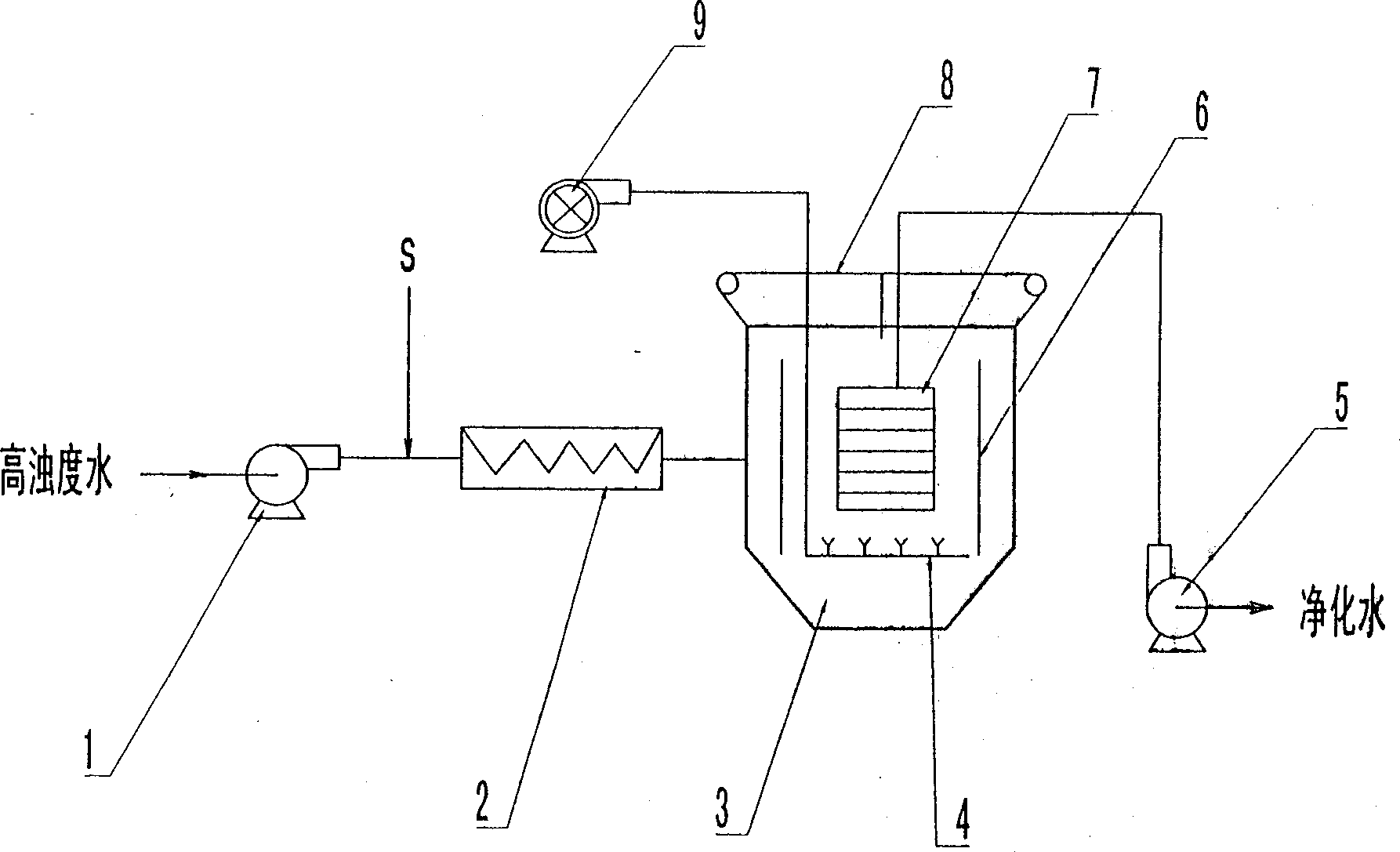

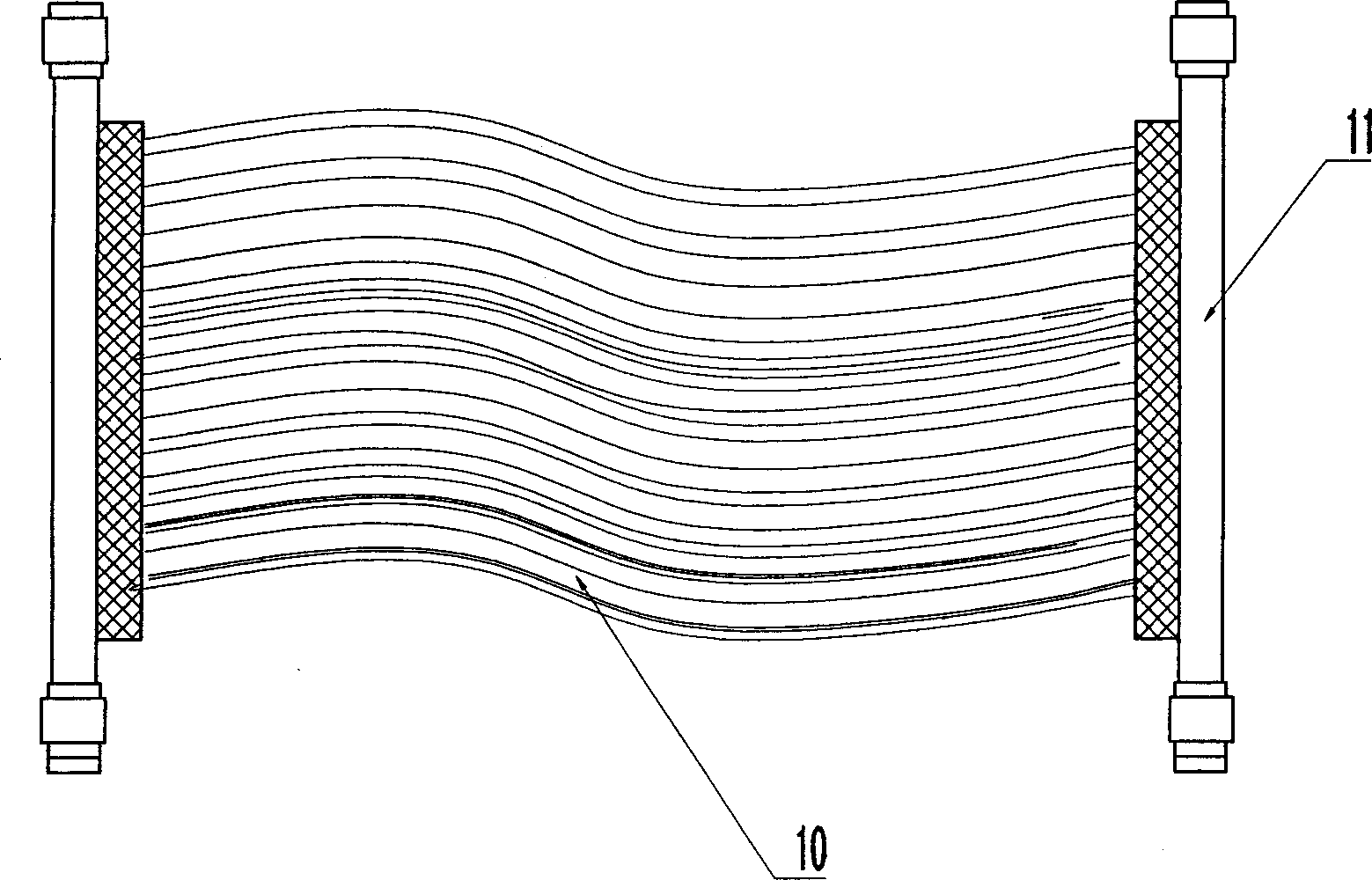

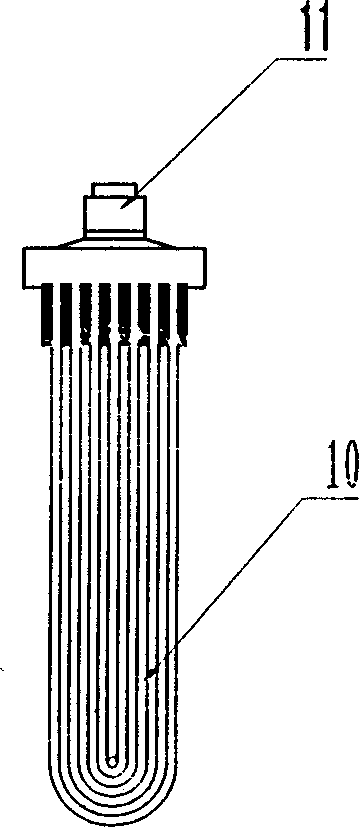

[0021] Such as figure 1 As shown, the treated high turbidity water is pumped into the pipeline mixer 2 by the pump 1, and at the same time, the flocculant S is added, and after the mixed flocculation reaction, it enters the treatment water tank 3, and the aeration device 4 is installed near the bottom of the water tank, and the aeration device 4 It is connected with the fan 9 by a pipeline, a hydrophilic hollow fiber microporous membrane module 7 is installed above the aeration device 4, and a partition 6 is installed inside the water tank. Purified water passes through the micropores on the wall of the hydrophilic hollow fiber microporous membrane 10, enters the inside of the hollow fiber microporous membrane, is sucked by the self-priming pump 5, and is discharged through the water collection pipe 11 of the membrane module. There are two structural forms of hollow fiber membrane modules, one is screen type, the hollow fiber microporous membranes 10 arranged in a screen shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com