Pressure sterilizing after-treatment method for flexible package

A technology of autoclave sterilization and flexible packaging, which is applied in the fields of food science, food preservation, application, etc., to shorten the production cycle, ensure the appearance, and ensure the production efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

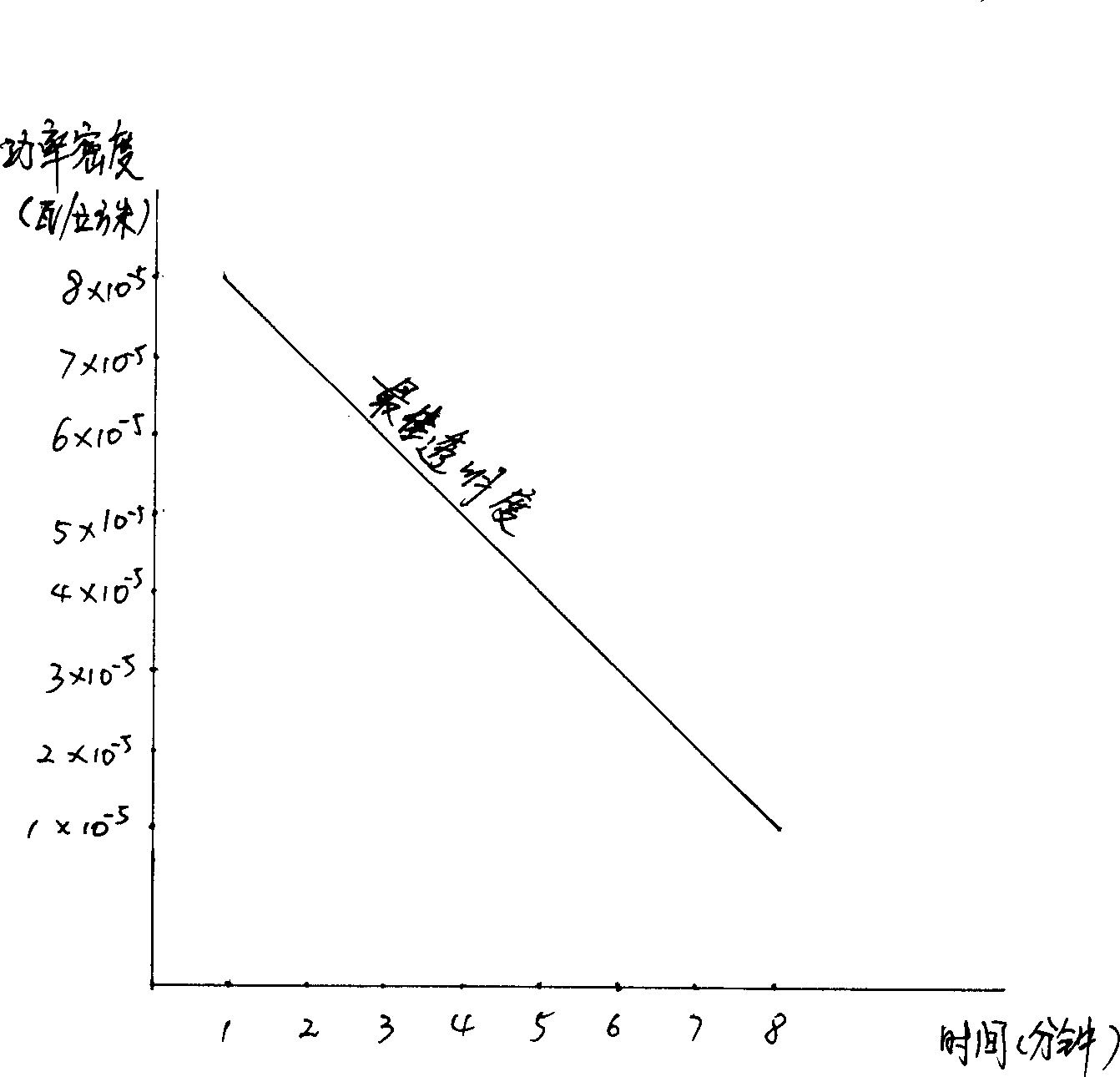

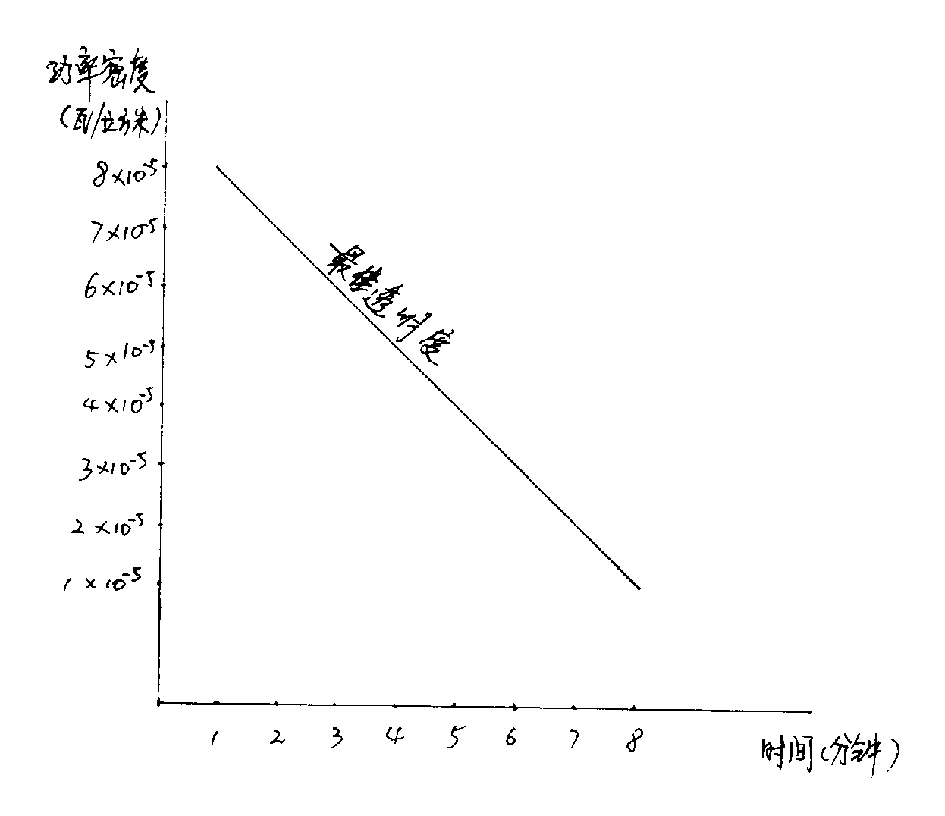

[0017] Embodiment 1, a microwave generator for soft packaging drying, the container material is made of stainless steel, the resonant cavity is made of anti-rust aluminum, the surface of the anti-rust aluminum is polished, anodized, and the microwave frequency is 2450±50MHz, and the continuous wave output power is 20KW. 7×10 -5 Watts / cubic meter, hot-pressed, infiltrated with steam, the color turns white and loses transparency. The flexible packaging is irradiated with microwave energy for 2 minutes, and then air-cooled after taking it out to restore the best transparency.

Embodiment 2

[0018] Embodiment 2. In the above embodiment, the power density is 8×10 -5 Watts / cubic meter, hot-pressed, infiltrated with steam, the color turns white and loses transparency. The flexible packaging is irradiated with microwave energy for 1 minute, and then air-cooled after taking it out to restore the best transparency.

Embodiment 3

[0019] Embodiment three, in embodiment one, adopt power density to be 1×10 -5 Watts / cubic meter, hot-pressed, infiltrated with steam, the color turns white and loses transparency. The flexible packaging is irradiated with microwave energy for 8 minutes, and then air-cooled after taking it out to restore the best transparency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com