Full-reflection curved mirror

A technology of total reflection and curved mirror, which is applied in the direction of mirrors, solar ray concentration, solar thermal devices, etc., and can solve problems such as short service life, insufficient coating firmness, and coatings that cannot achieve total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

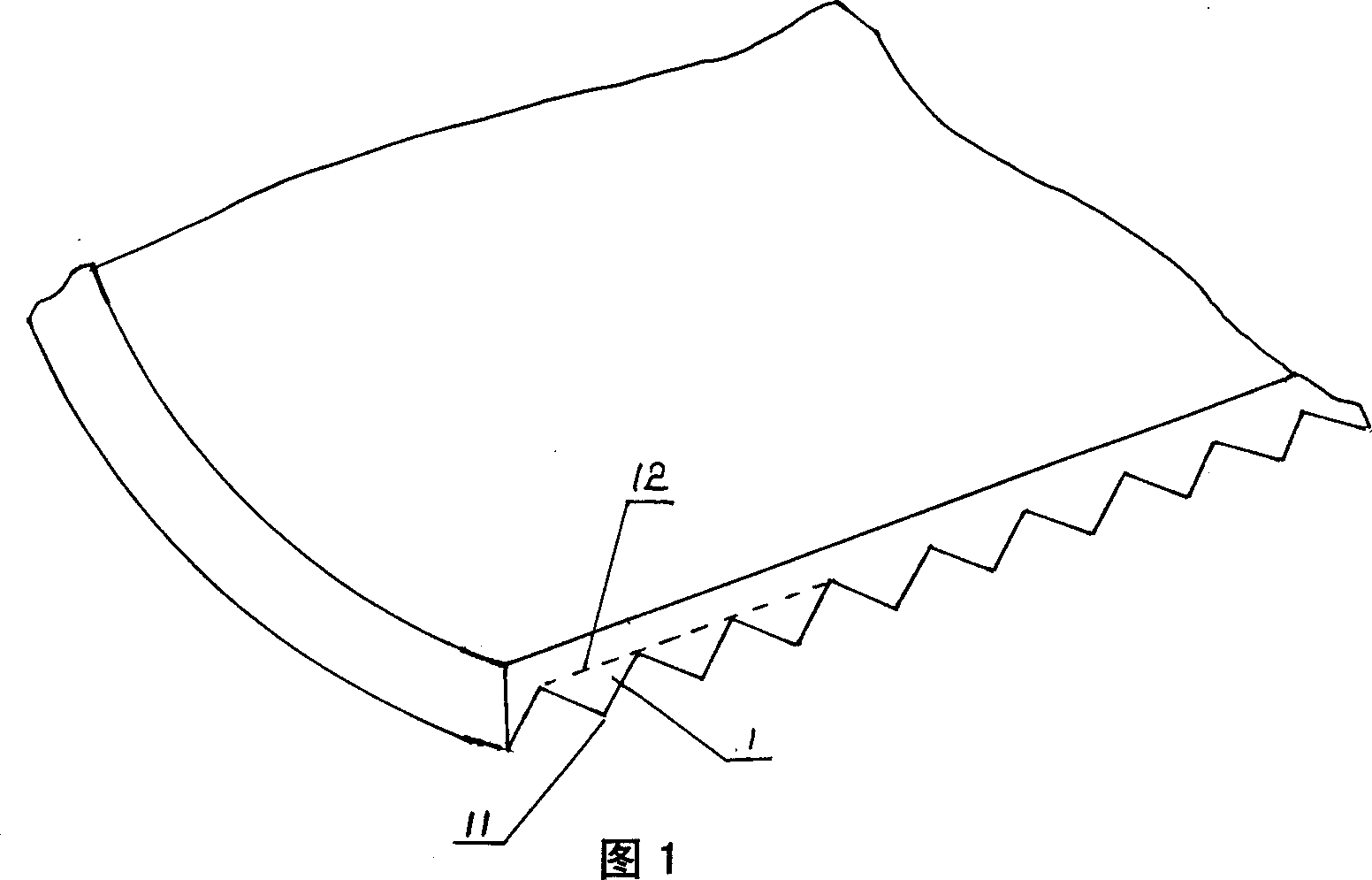

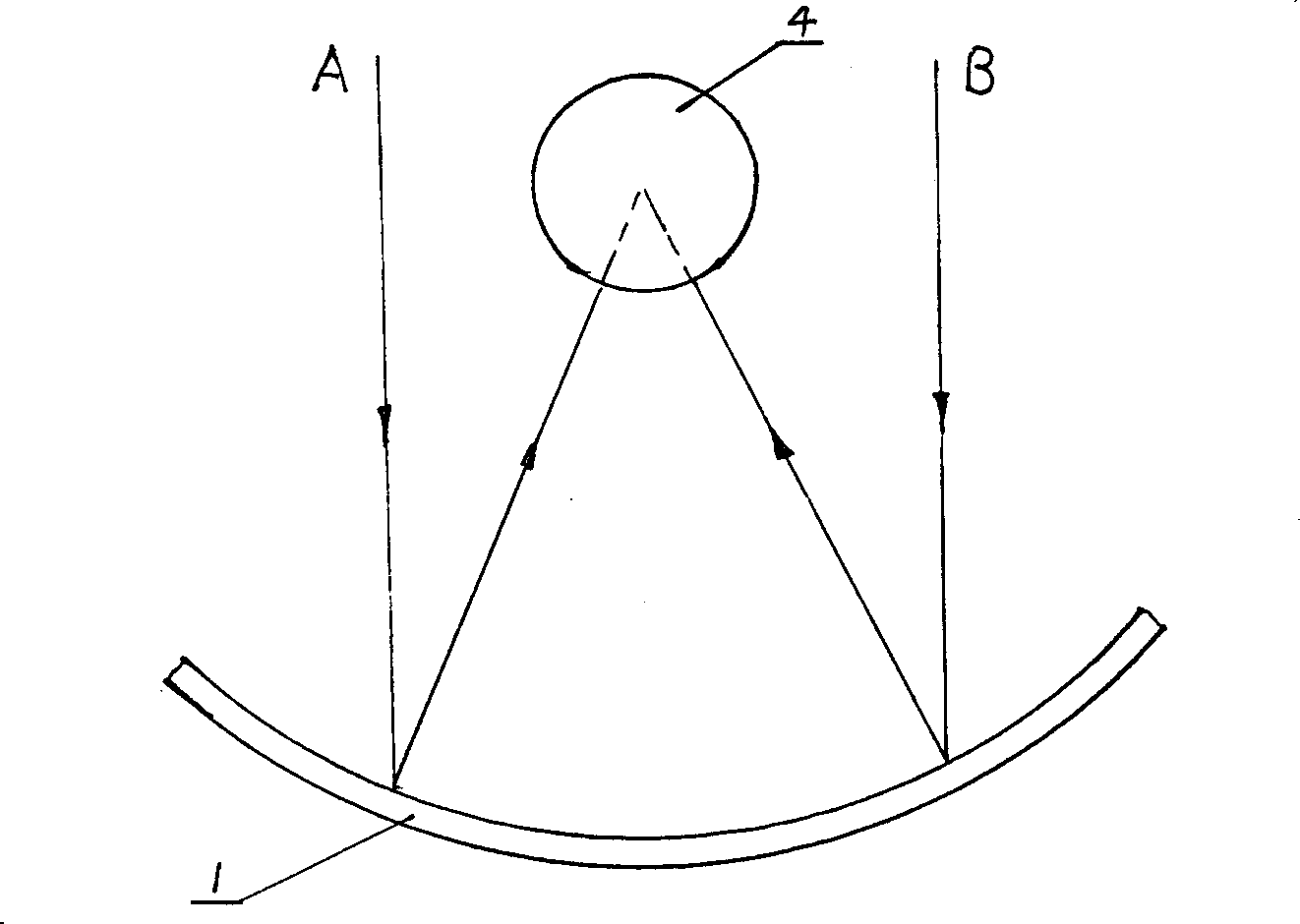

[0015] Referring to Fig. 1, the structure of this embodiment is that one layer of closely arranged porro prisms 1 are formed on one side of the optical glass, its right-angled prism 11 faces one example, and its slopes 12 are all on the same plane, and serve as the incident surface of light. In order to make the reflected light converge, it has a curved surface (paraboloid).

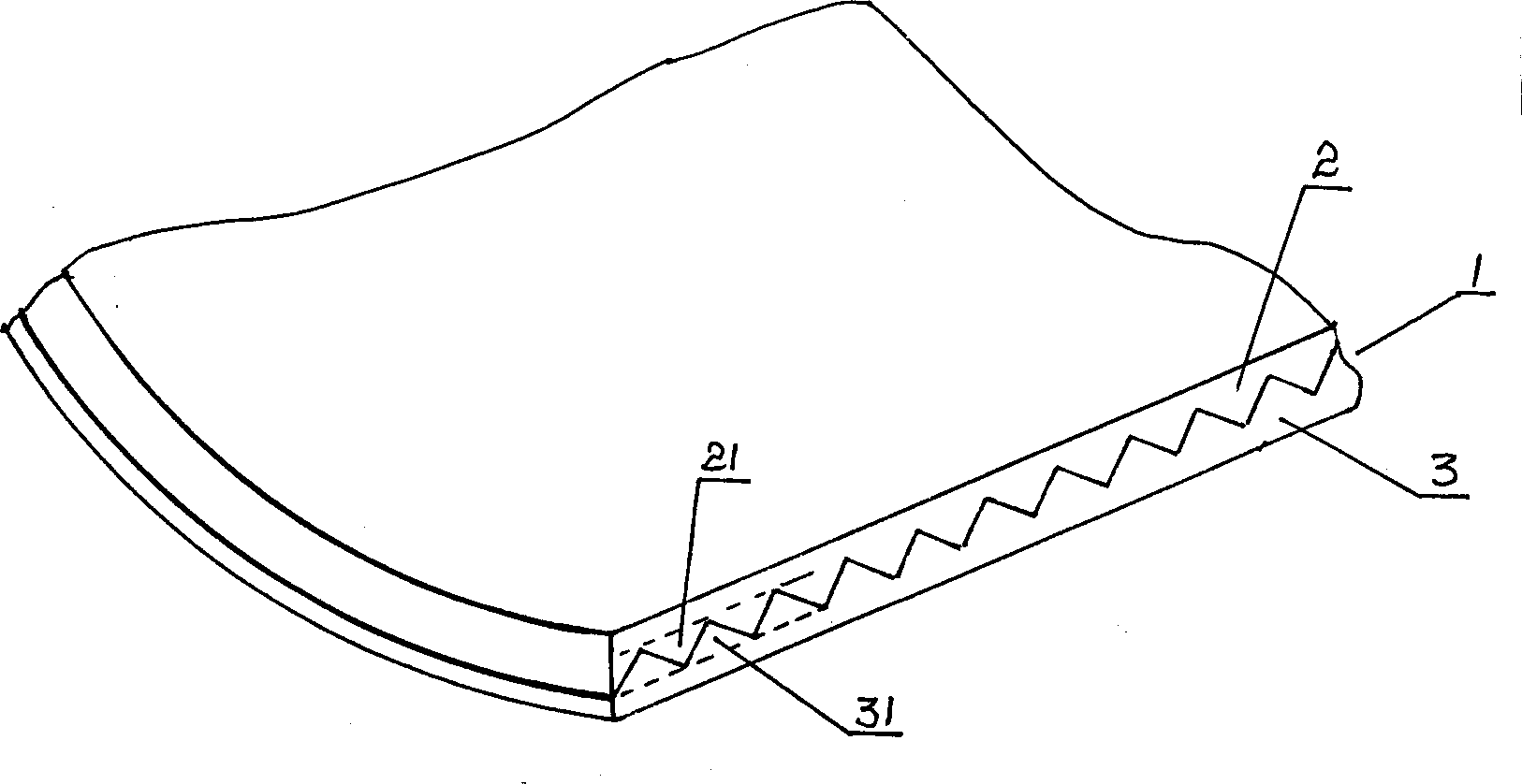

[0016] see figure 2 , the Porro prism 11 is composed of a high-refractive index reflective layer 2 and a low-refractive-index carrier layer 31, and closely arranged Porro prisms 21 are arranged on the high-refractive index reflective layer 2 , the carrier layer 3 with a low refractive index has the same prism 31 as the above-mentioned Porro prism 21, and the two are closely overlapped together to form a total Porro prism 1, and the refractive index n of the reflective layer 2 and the carrier layer 3 will satisfy i c <45°,

[0017] ie sin -1 which is n ′ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com