Method for regenerating conductive adsorbent carrying organic matter

A technology of adsorbent regeneration and organic matter, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of increased construction volume, uneconomical, and difficult temperature adjustment of activated carbon cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

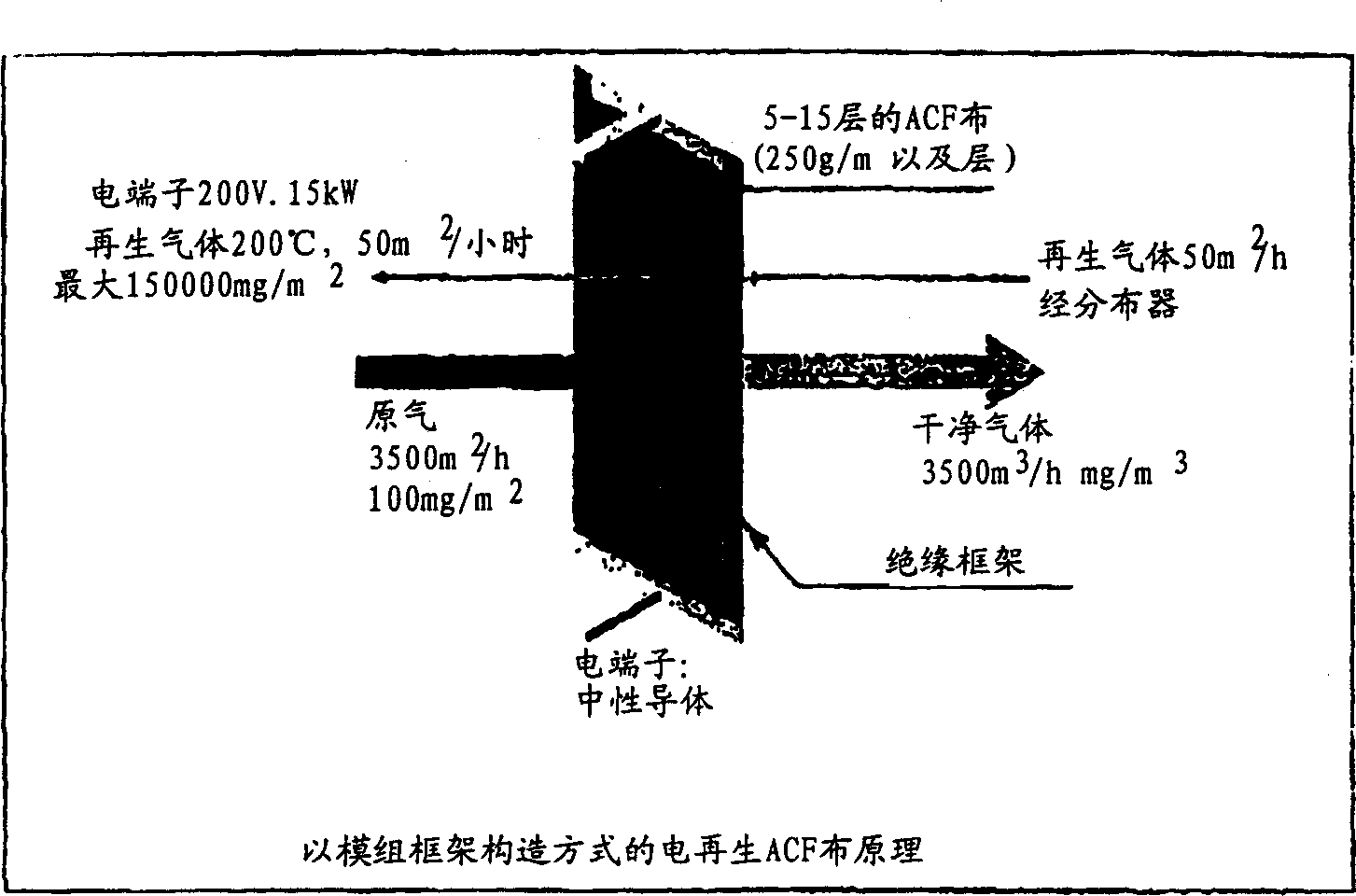

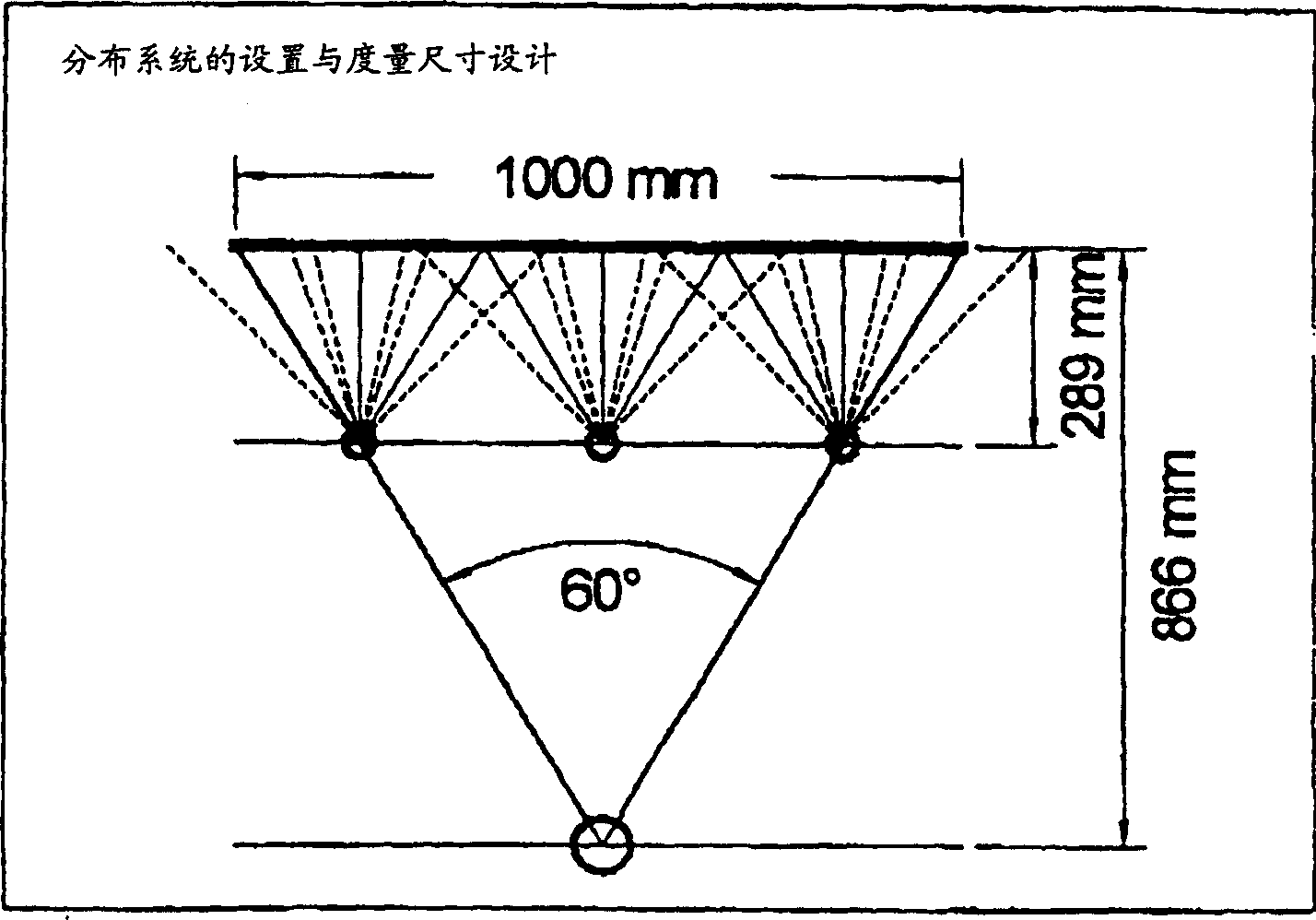

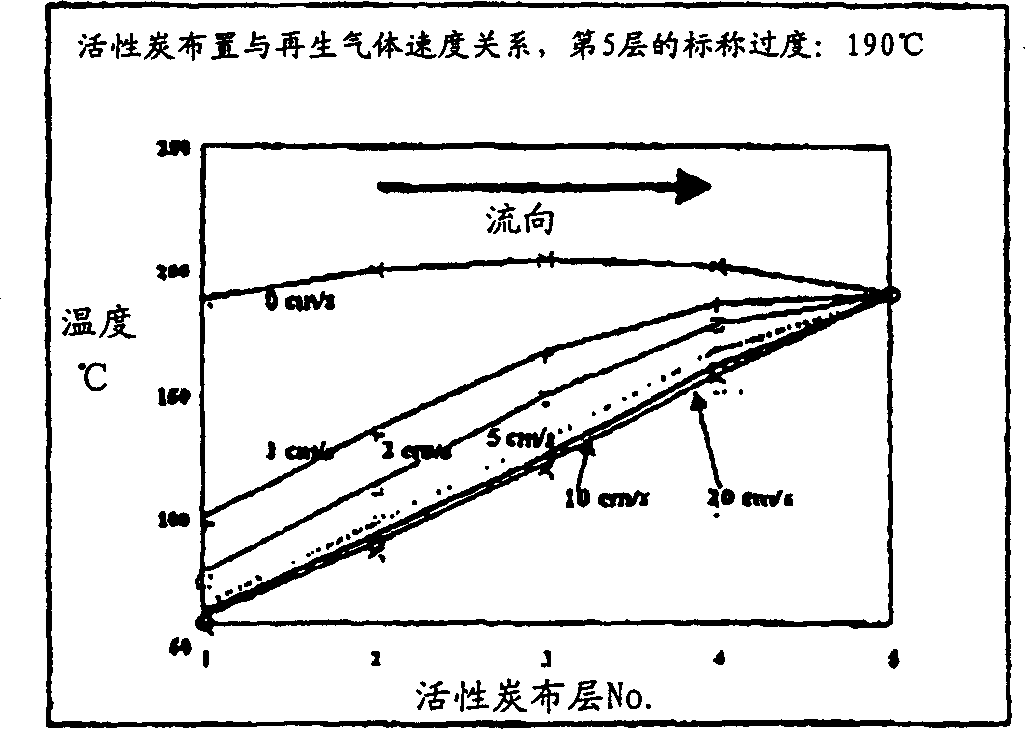

[0025] Experimental equipment in a laboratory (its measurement size is designed to have 0~30m 3 air volume per hour) in accordance with the following instructions to conduct experiments for adsorption and desorption, there is a rhythm of time intervals when desorption is performed.

[0026] Such as Figure 4 As shown, in the adsorber 1 of the laboratory, the load is carried in the direction shown from the raw gas line 5 via the filter 2 to the clean air line 4 . Here, five layers of ACF are sandwiched in a filter frame. The supply line 3 and the lead-off line 6 are closed during the loading phase. The carrying concentration of the solvent toluene is selected to be about 40mg / m 3 , wherein the relative humidity of the raw gas is maintained at 50% at 23°C.

[0027] When the free filtering area of the filter is 0.07m in width and 0.21m in height, the speed on it is 0.3m / s. This experiment has been carried out until the breakthrough concentration is 10% of the original gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com