Illuminant semiconductor element and method for mfg. same

A technology for light-emitting elements and semiconductors, which is applied in semiconductor devices, semiconductor lasers, electrical components, etc., and can solve problems such as the increase in the price of the substrate and the increase in the series resistance of the chip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, details of the present invention will be described using illustrated embodiments.

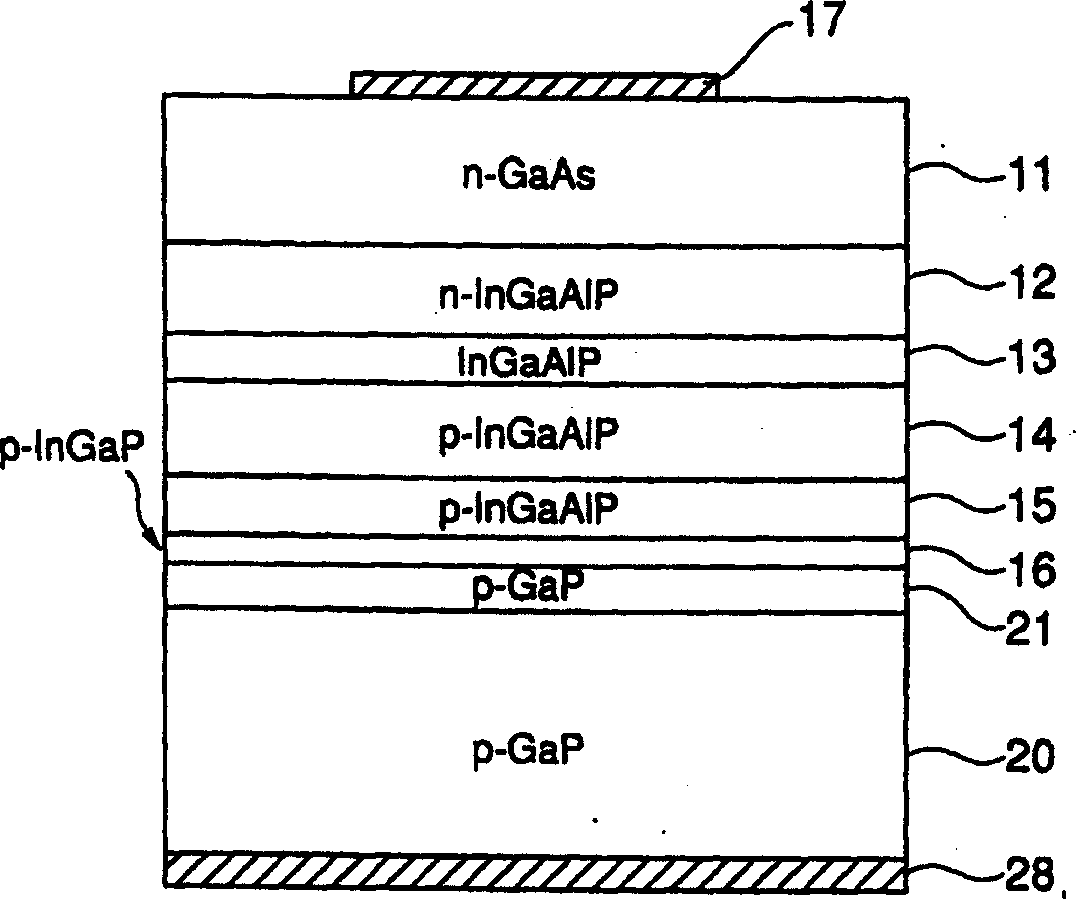

[0036] figure 1 The cross-sectional view of is showing the element configuration of the bonding type LED of one embodiment of the present invention.

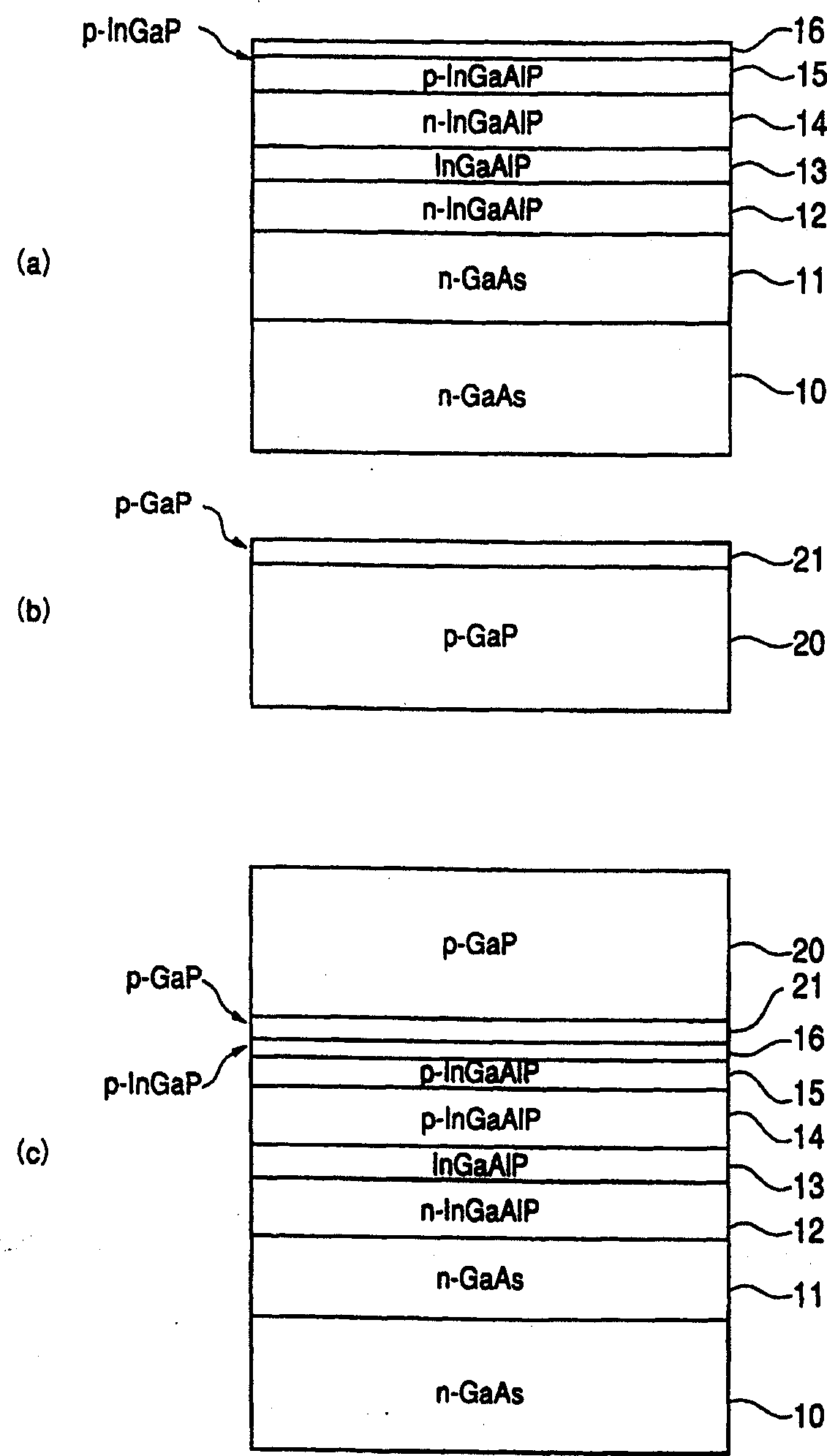

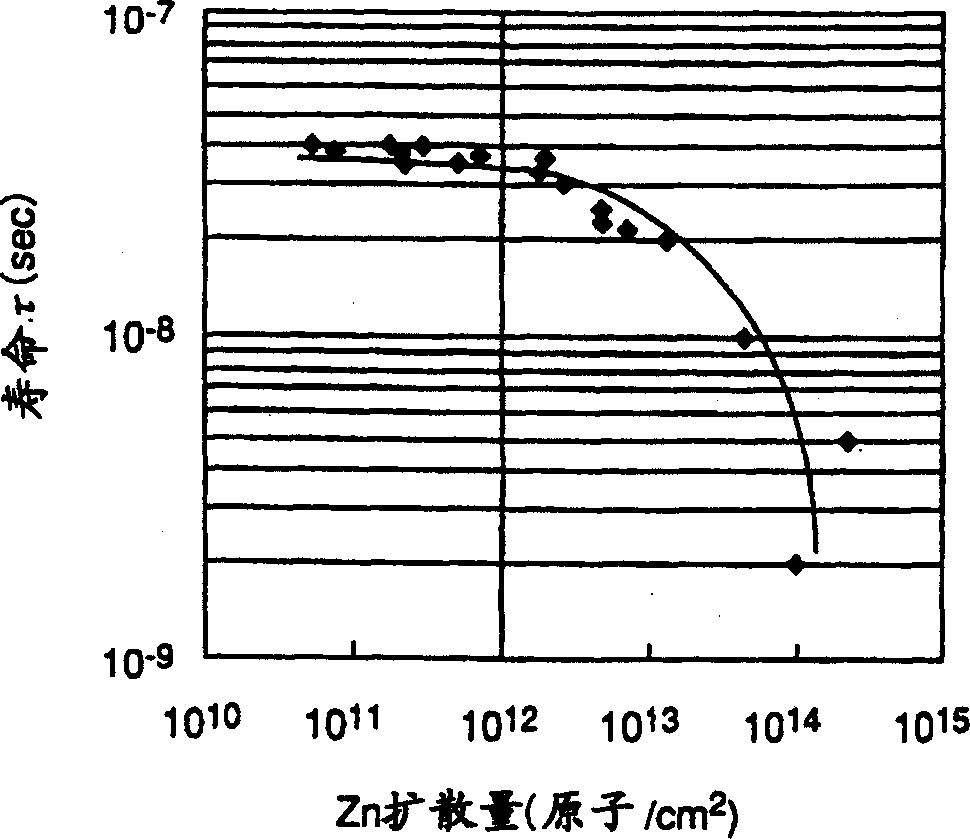

[0037] On the p-type GaP substrate 20, a high-concentration p-type GaP buffer layer 21 is formed, on which the p-type InGaP bonding layer 16, the Zn diffusion prevention layer 15 made of p-type InGaAlP, and the p-type InGaAlP are directly bonded. A cladding layer 14, an InGaAlP active layer 13, an n-type InGaAlP cladding layer 12, and an n-type GaAs current diffusion layer 11 are laminated. Then, on the lower surface of GaP substrate 20 , p-side electrode 28 is formed, and on the upper surface of current diffusion layer 11 , n-side electrode 17 is formed.

[0038] In addition, a double heterostructure structure portion contributing to light emission is also formed in each of the layers 12 , 13 , and 14 described above. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com