Circuit for producing high voltage used for toner powder system printer

A technology for generating circuits and printers, applied in the direction of electrical recording process applying charge pattern, equipment for electrical recording process applying charge pattern, control/adjustment system, etc. lowering etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

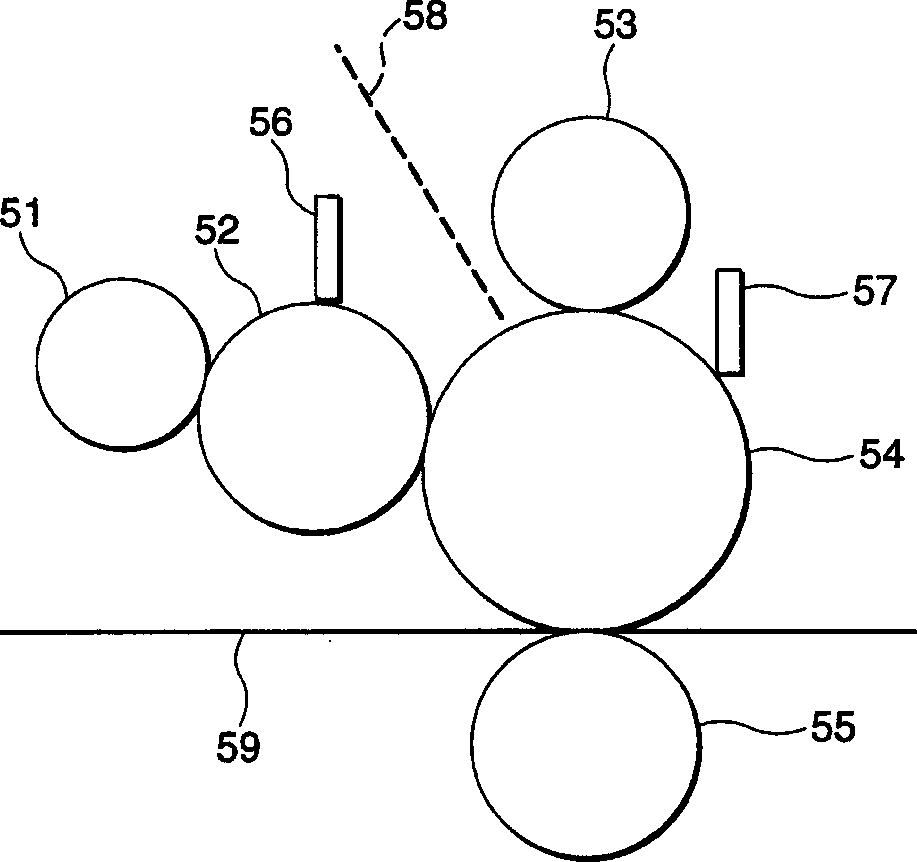

[0036] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

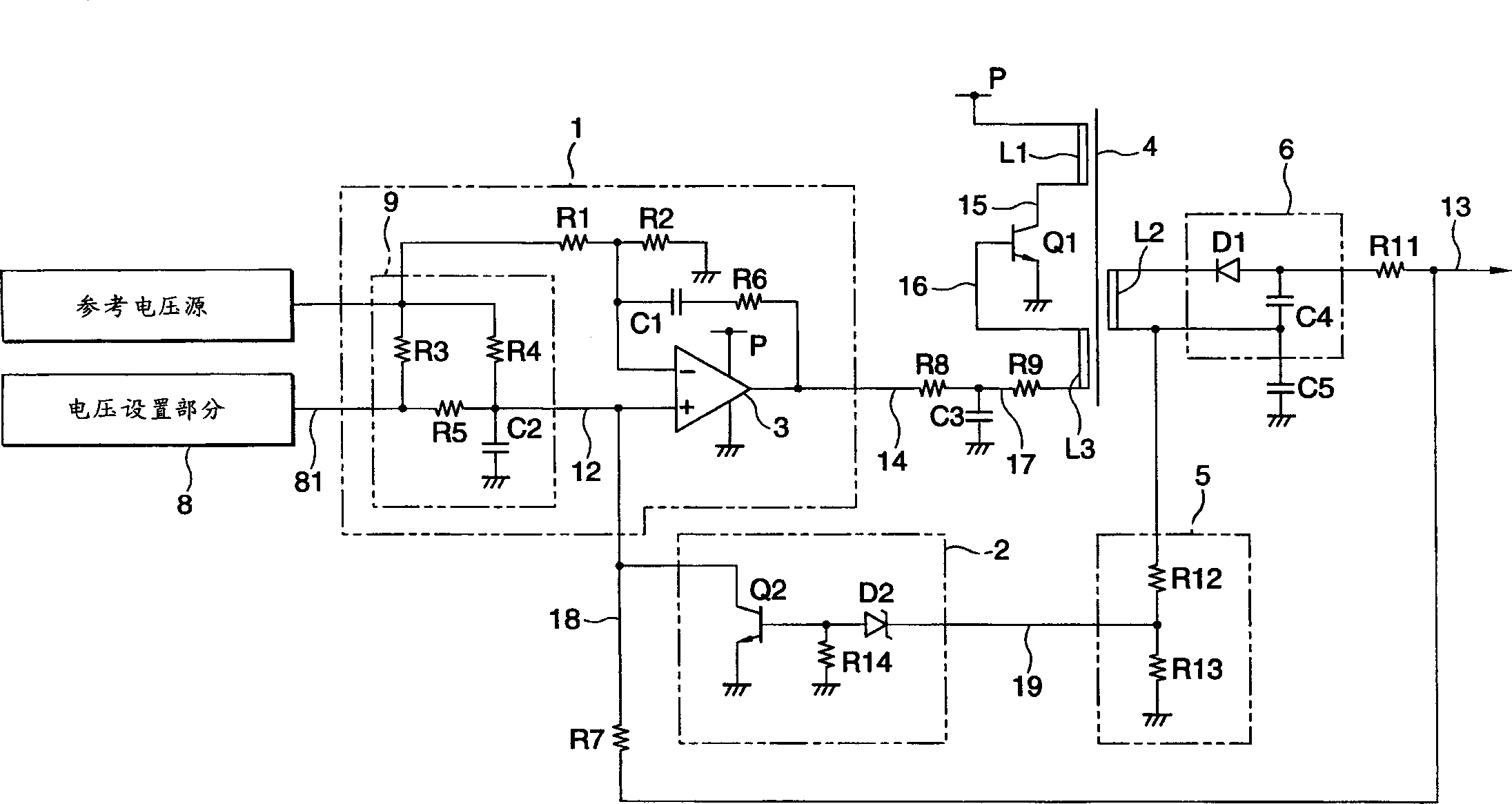

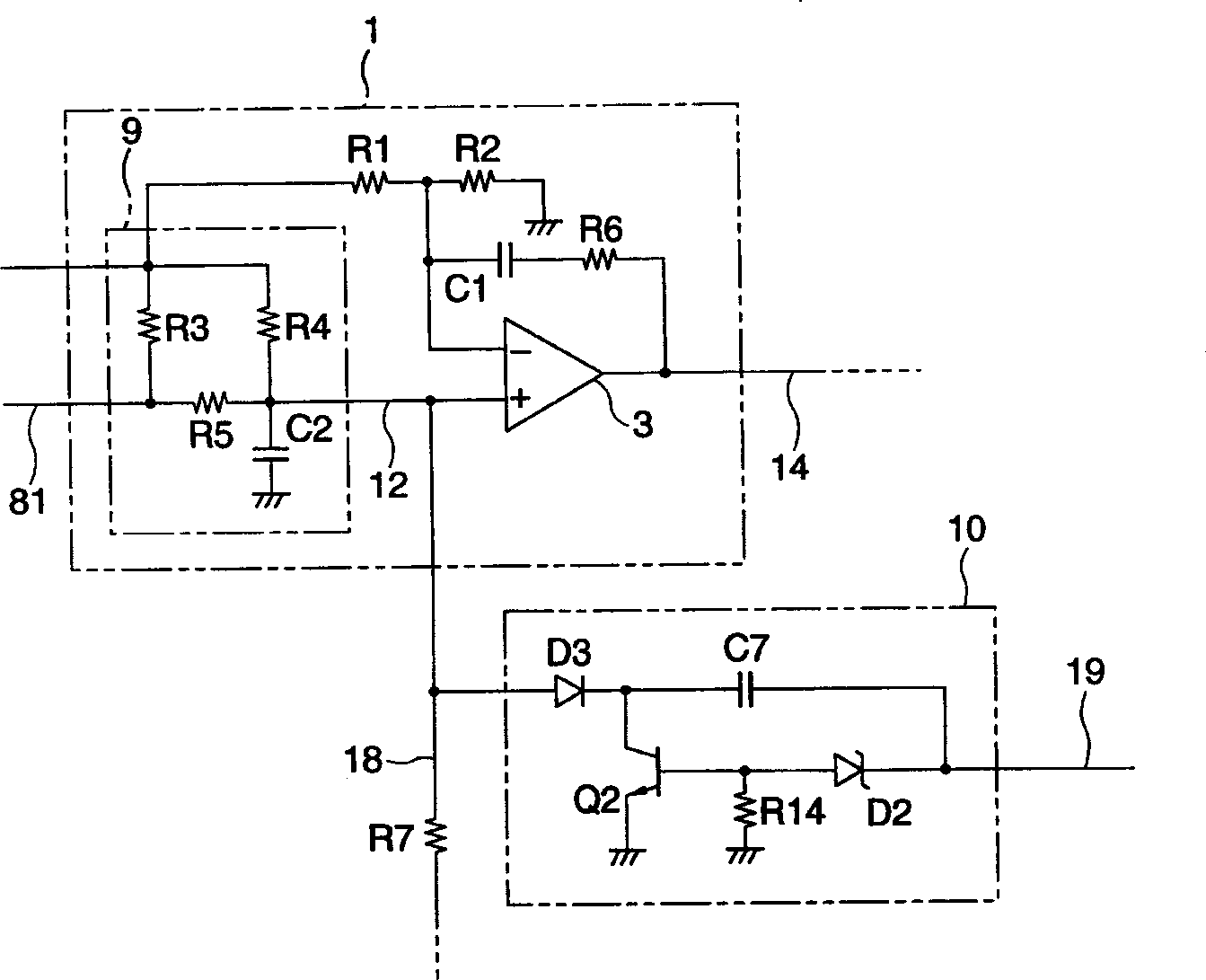

[0037] figure 1 is a circuit diagram showing the electrical connection of the first embodiment of the high voltage generating circuit for a toner system printer according to the present invention, showing a structure in which the output voltage varies with a voltage of, for example, about -1100V. and Figure 7 The same elements in the Figure 7 same label.

[0038] figure 1 Among them, the reference voltage source 7 is a component for outputting a voltage that is accurately stabilized to, for example, 10V. Also, the voltage setting section 8 is a part for setting the voltage of the secondary output 13 and for setting the voltage of the secondary output 13 at the duty ratio of the PWM signal to be output. The output of the voltage setting section 8 is an open-drain output.

[0039] The voltage control circuit 1 is a means for sending a DC voltage contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com