Vane wheel of low-noise scavenger fan

A ventilation fan, low-noise technology, applied in the components of the pumping device for elastic fluids, non-variable-capacity pumps, machines/engines, etc. It is not a big problem, and achieves the effect of low noise, avoiding eddy current and avoiding disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

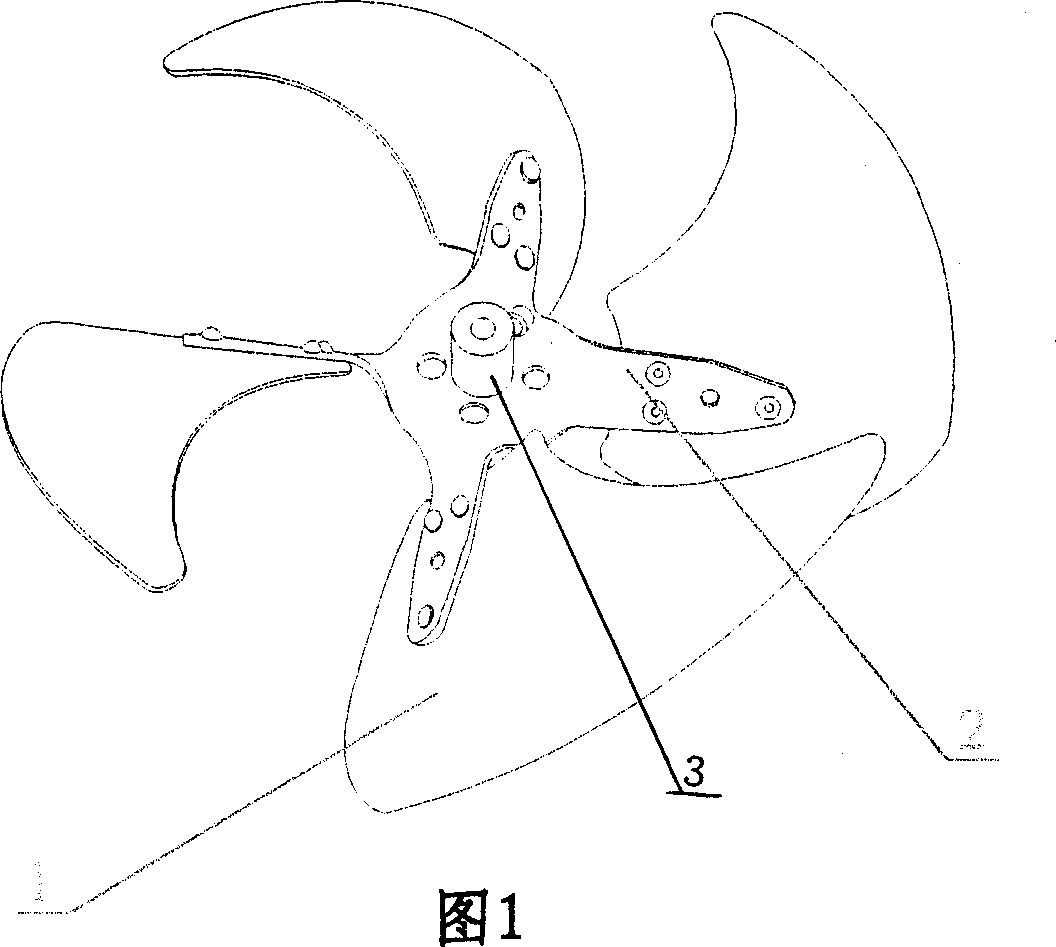

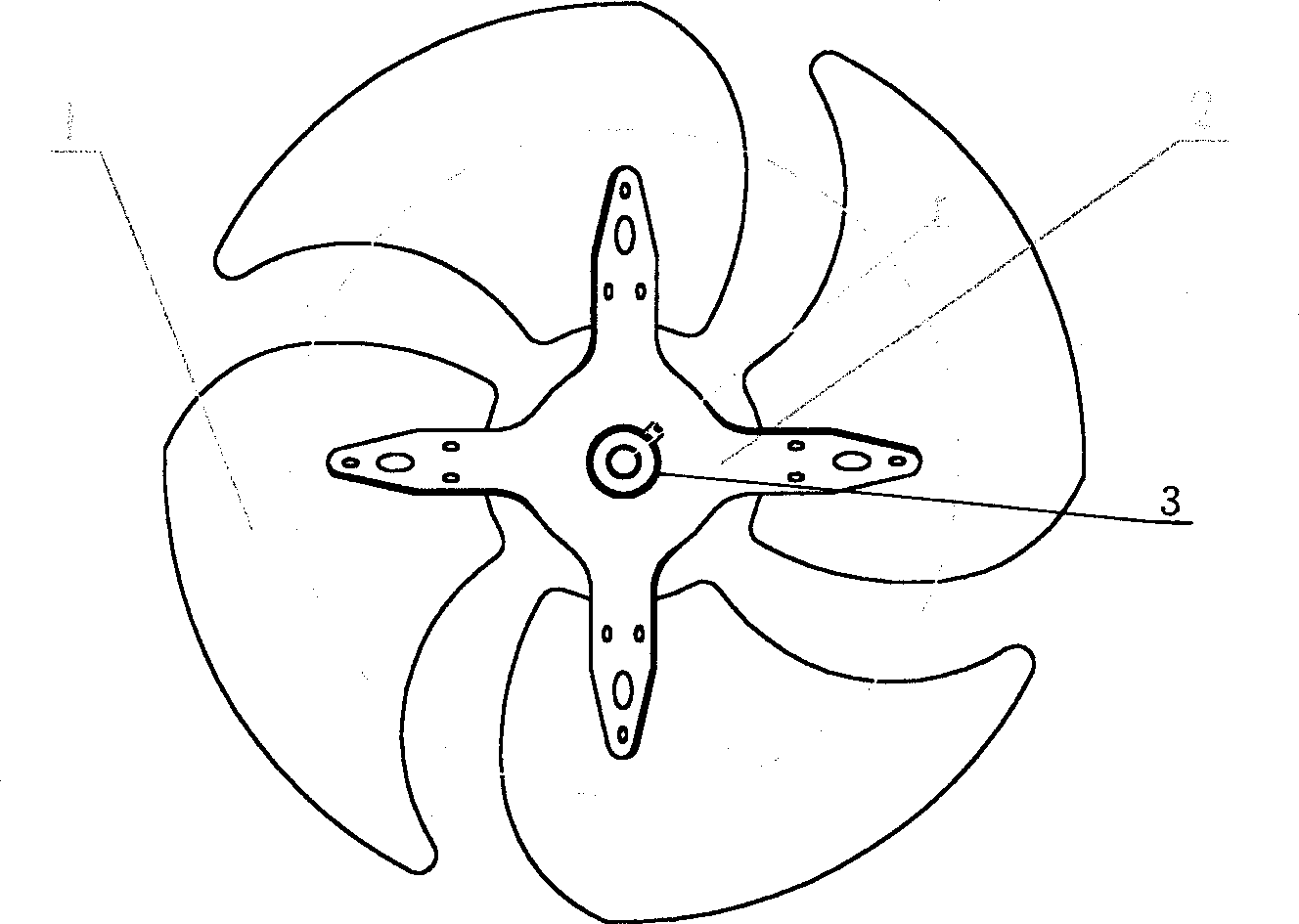

[0028] Figure 1, figure 2 As shown, a cross-shaped blade frame 2 is made of a steel plate, and its center is a shaft sleeve 3. On the four arms of the blade frame 2, four blades 1 are respectively connected or welded by fasteners or rivets, each The blades are all twisted and forward-leaning, and adopt variable circulation design. That is, the leaf surface distribution on the blade tends to be in front of the direction of rotation and toward the outer edge. From the root of the blade to its outer edge, the area of each part of the leaf surface gradually increases, and its distribution is inclined toward the leading edge. The different chord lengths b on the leaf surface corresponding to different primitive-level radii r increase with the increase of r. As for the different installation angle α of the blade surface, it varies with the radius r of different primitives, and the blade surface is distorted. As r increases, the installation angle α tends to decrease. The relevan...

Embodiment 2

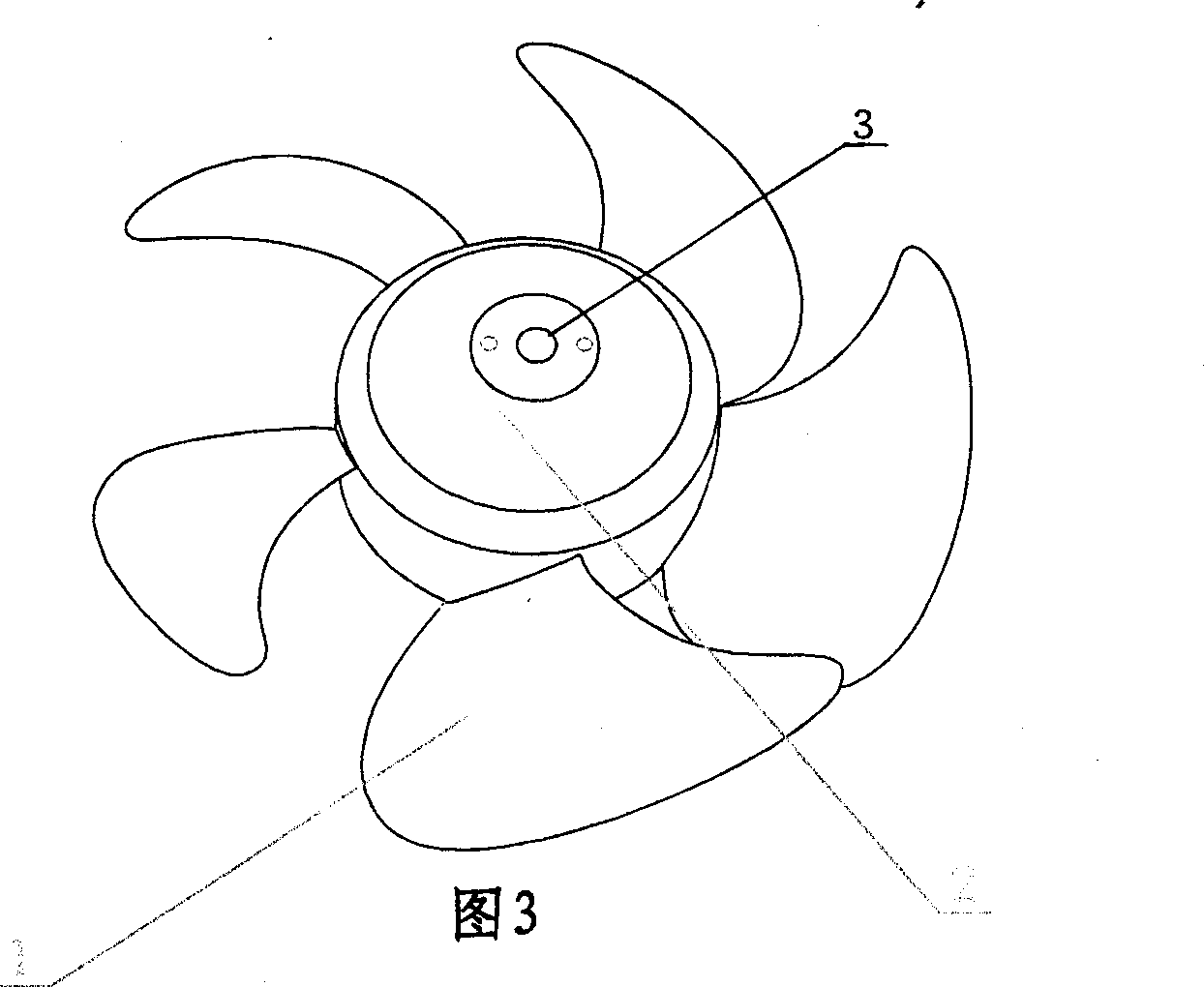

[0036] As shown in Figure 3, Figure 4 Shown, with embodiment 1, just, make the whole impeller of 5 blades with engineering plastics, 5 blades 1 are directly connected on the hub disc as blade frame 2, and axle sleeve 3 is arranged in the center. The arrangement of each blade 1 also adopts a twisted forward-leaning design. The relevant parameters are listed in the table below. All the other are with embodiment 1.

[0037] parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com