Method for preventing bus voltage from excessing

A bus voltage, DC bus voltage technology, applied in the direction of electrical components, control generator, motor generator control, etc., to achieve the effect of smooth deceleration process, prevent overvoltage fault, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

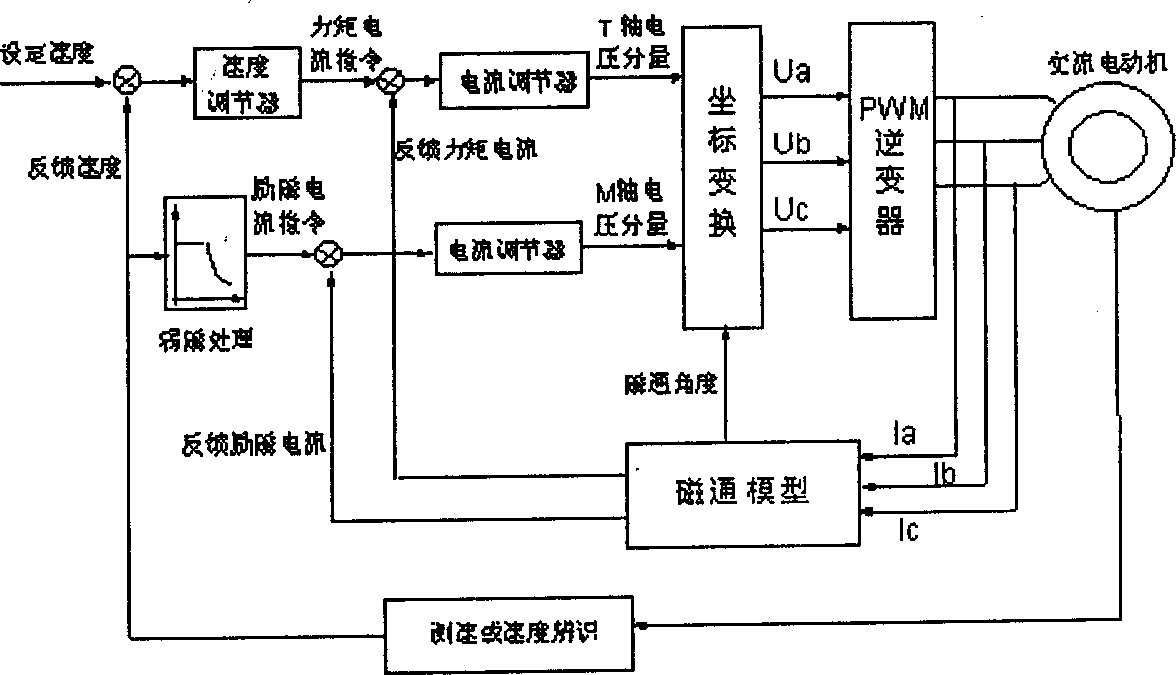

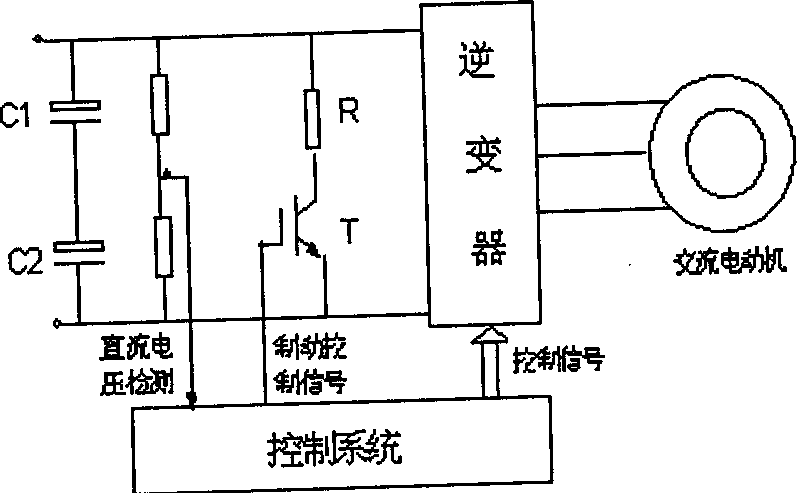

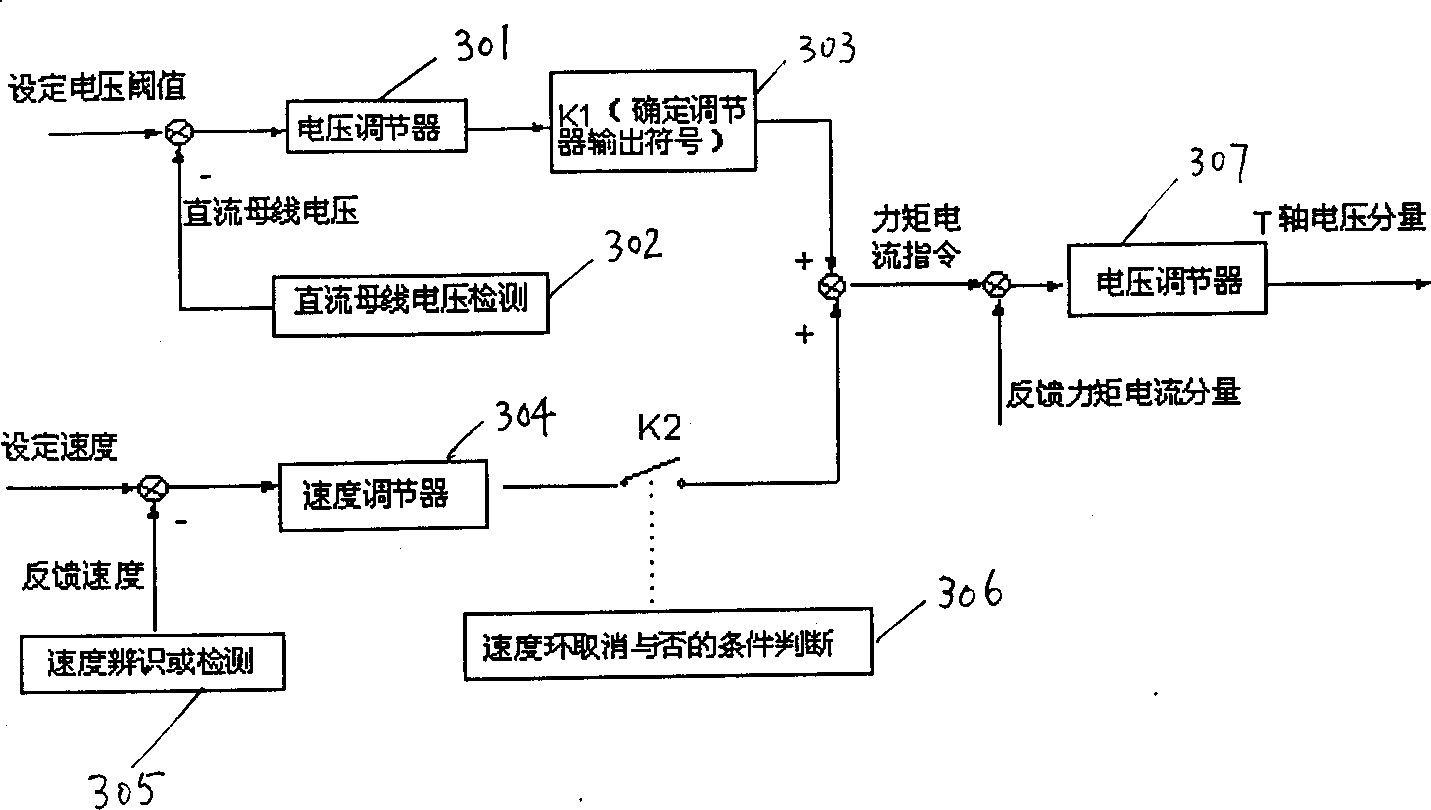

[0023] The method proposed by the present invention is to form a closed-loop control of the DC bus voltage of the frequency converter during the deceleration process of the motor, and ensure that the DC bus voltage of the frequency converter will not exceed the set voltage threshold by adjusting the speed of the motor, thereby preventing the bus voltage from pumping too high caused by the failure. How to add the frequency converter DC bus closed-loop control to the vector control system is the key point of the method of the present invention.

[0024] In the vector control system of the AC motor, the motor operates below the fundamental frequency for constant flux control, at this time the stator current excitation component is the no-load current value of the motor, and above the motor fundamental frequency for constant power control, at this time the stator excitation current Changes according to the law of field weakening control, that is to say, the excitation current comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com