Ropeway carriage speed control method

A speed control and acceleration control technology, applied in cable railways, motor vehicles, railway vehicles, etc., can solve problems such as reducing hardware reliability, increasing the possibility of system failure, and rushing to stations, and achieves the effect of smooth acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

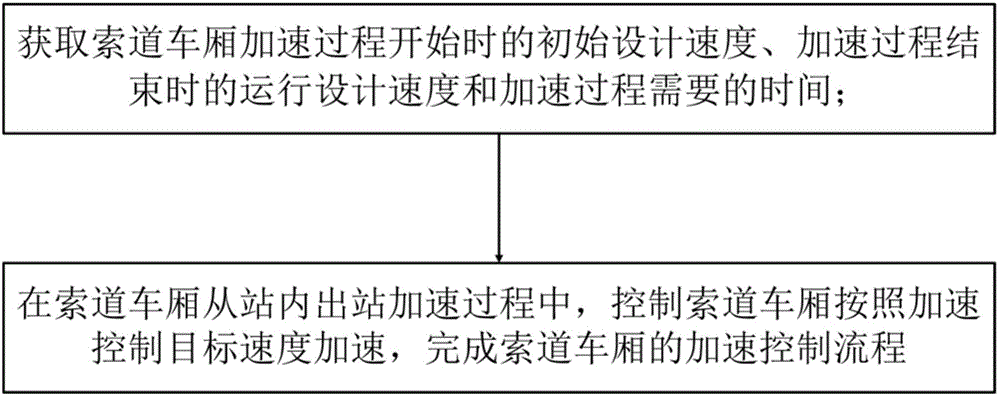

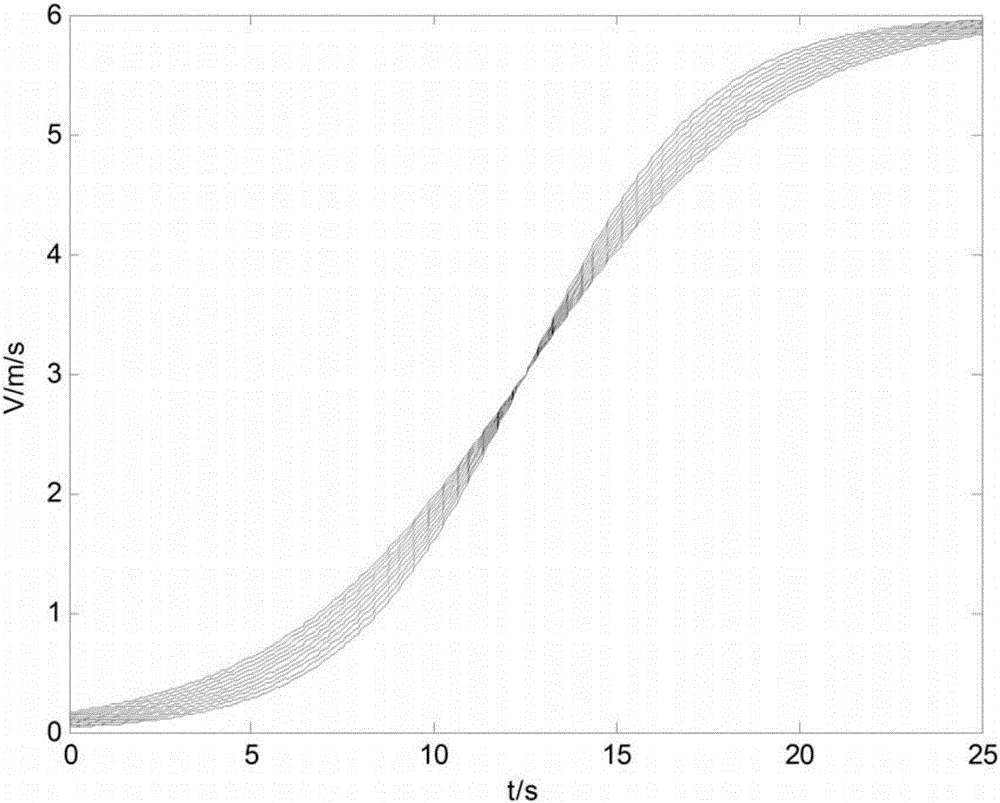

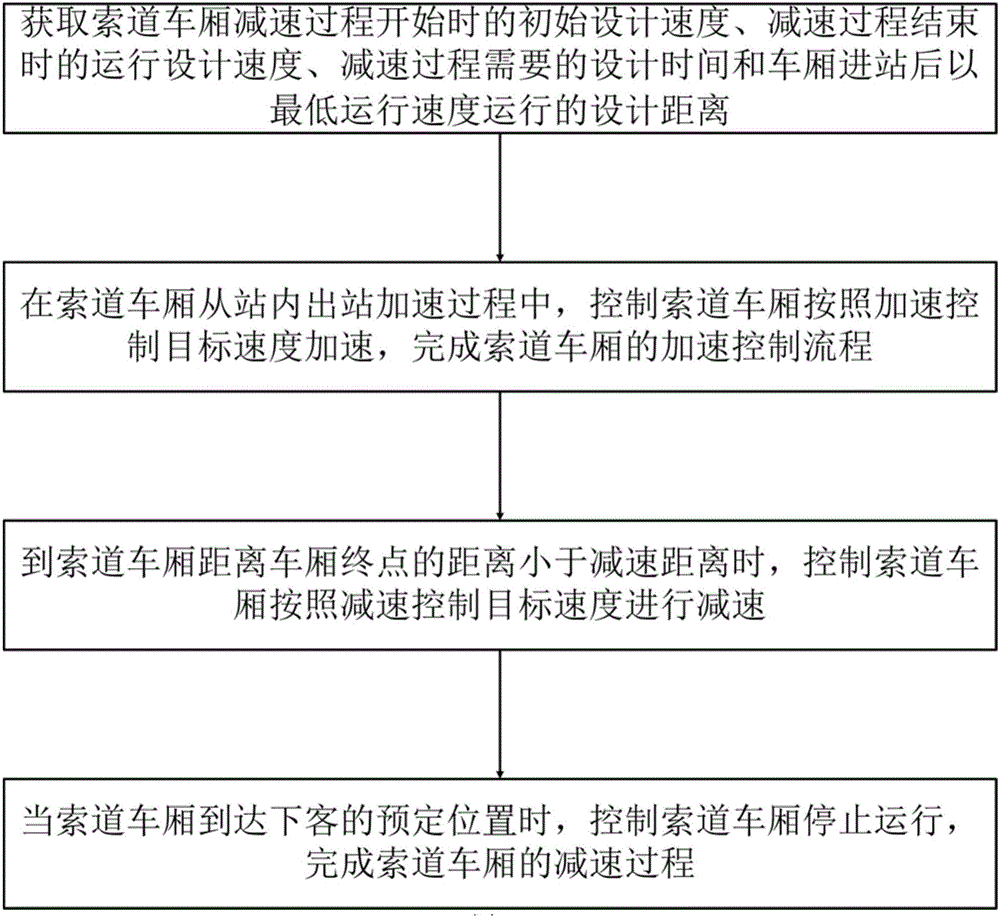

[0030] Such as figure 1 Shown is the schematic diagram of the cableway car acceleration control process of the present invention: the acceleration control process of the cableway car comprises the following steps:

[0031] S1. Obtain the initial design speed (generally 0) at the beginning of the cableway car acceleration process, the running design speed at the end of the acceleration process and the time required for the acceleration process;

[0032] S2. During the acceleration process of the cableway carriage from the station, control the acceleration of the ropeway carriage according to the following formula to complete the acceleration control process of the ropeway carriage:

[0033] y ( t ) = a 0 + a 1 - a 0 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com