Recordmedium, its preparing process, and imaging method using said record medium

A recording medium, single-layer technology, used in replication/marking methods, papermaking, textiles and papermaking, etc., which can solve the problems of high color development density, less ink bleeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

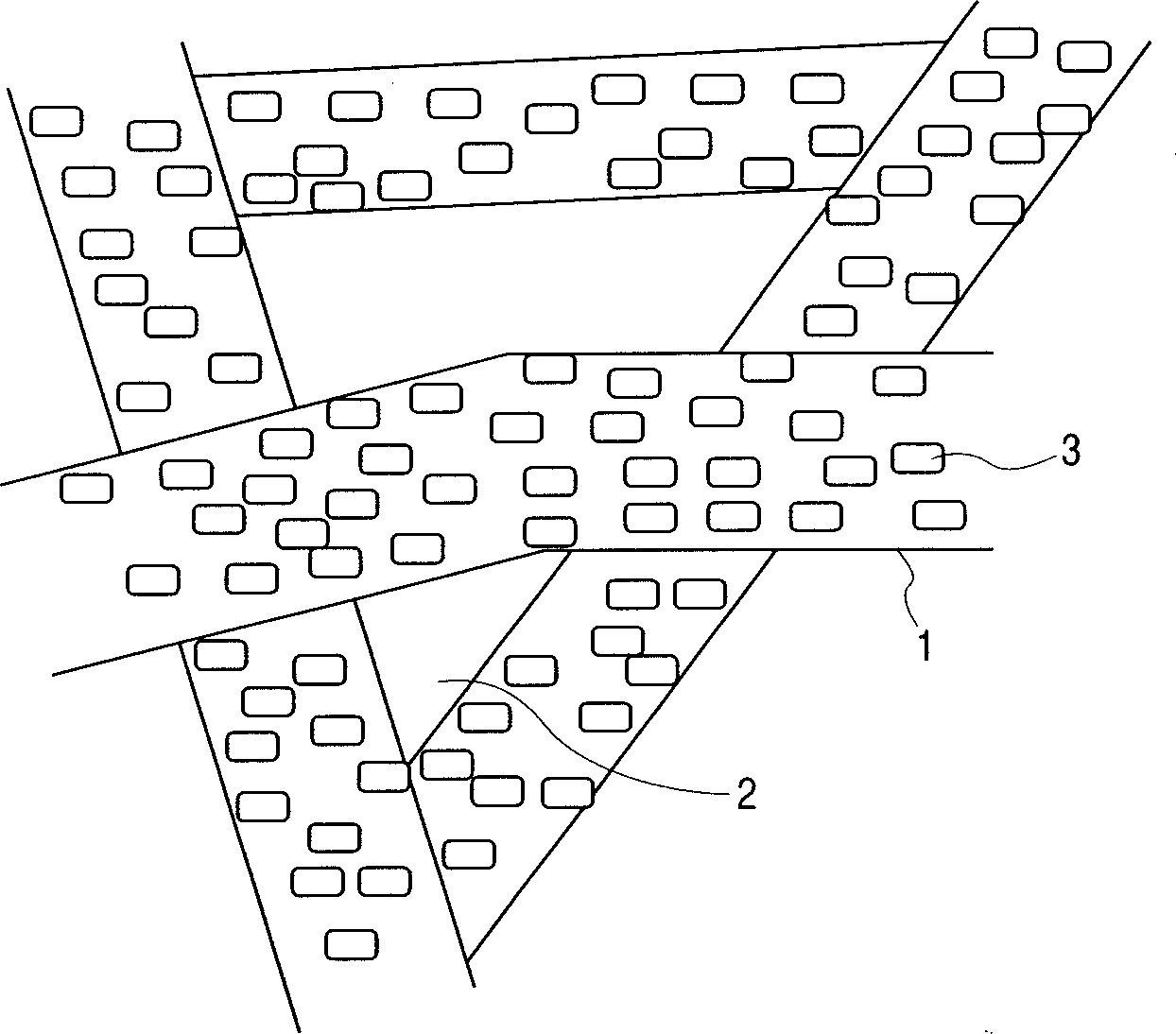

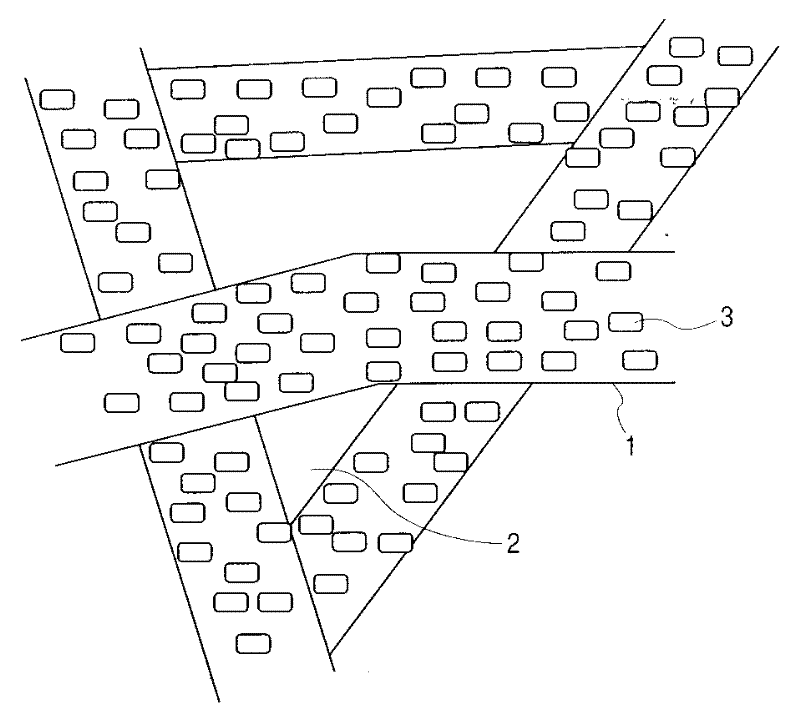

Image

Examples

example 1

[0097] Commercially available LBKP as a source pulp was beaten using a double-disc refiner to obtain a beaten papermaking stock (A) having 300 mL of Canadian Standard Freeness (C.S.F). Similarly, commercially available LBKP as a source pulp used as a base layer was beaten using the same equipment to obtain a beaten papermaking stock (B) having 450 mL of Canadian Standard Freeness (C.S.F). The beaten paper stock (A) and the beaten paper stock (B) were mixed at a dry weight ratio of 9:1 to prepare a paper stock.

[0098] Alumina hydrate liquid dispersion (solid matter content: 10% by weight) was prepared by dispersing alumina hydrate having the boehmite structure described in Example 1 of Japanese Patent Application Laid-Open No. 9-99627 in deionized water. A cationic resin liquid dispersion was prepared by dispersing a cationic resin, Weisstex H-90 (trade name, manufactured by Nagase Kasei Kogyo K.K., active ingredient content: 45%) in deionized water. The alumina hydrate liqu...

example 4

[0102] The beaten paper stock (A), the beaten paper stock (C) and the beaten paper stock (D) were mixed in a dry weight ratio of 8:1:1 to prepare a paper stock. Paper was manufactured using the same paper machine as in Example 1 so as to have the same paper basis weight as in Example 1. Then, coating was performed with the same on-machine coating liquid in the same manner and in the same amount as in Example 1. Smoothing the paper is carried out in the same manner as in Example 1. Thus, a recording medium is obtained. Its feel is similar to traditional plain paper. Table 1 shows the properties of the resulting recording media.

[0103] Typical effects of the present invention are as follows:

[0104] (1) Excellent ink absorption performance can be obtained without causing sticking of paper or ink strike-through, even if printing is performed on an ultra-high-speed printer having a solid line head.

[0105] (2) Even at high-speed printing, excellent color developing perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com