Thermoplastic multilayer composites

A multi-layer composite material, thermoplastic technology, applied in the direction of rigid pipe, layered products, thin material processing, etc., can solve problems such as no mention, stress cracking, and reduced barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

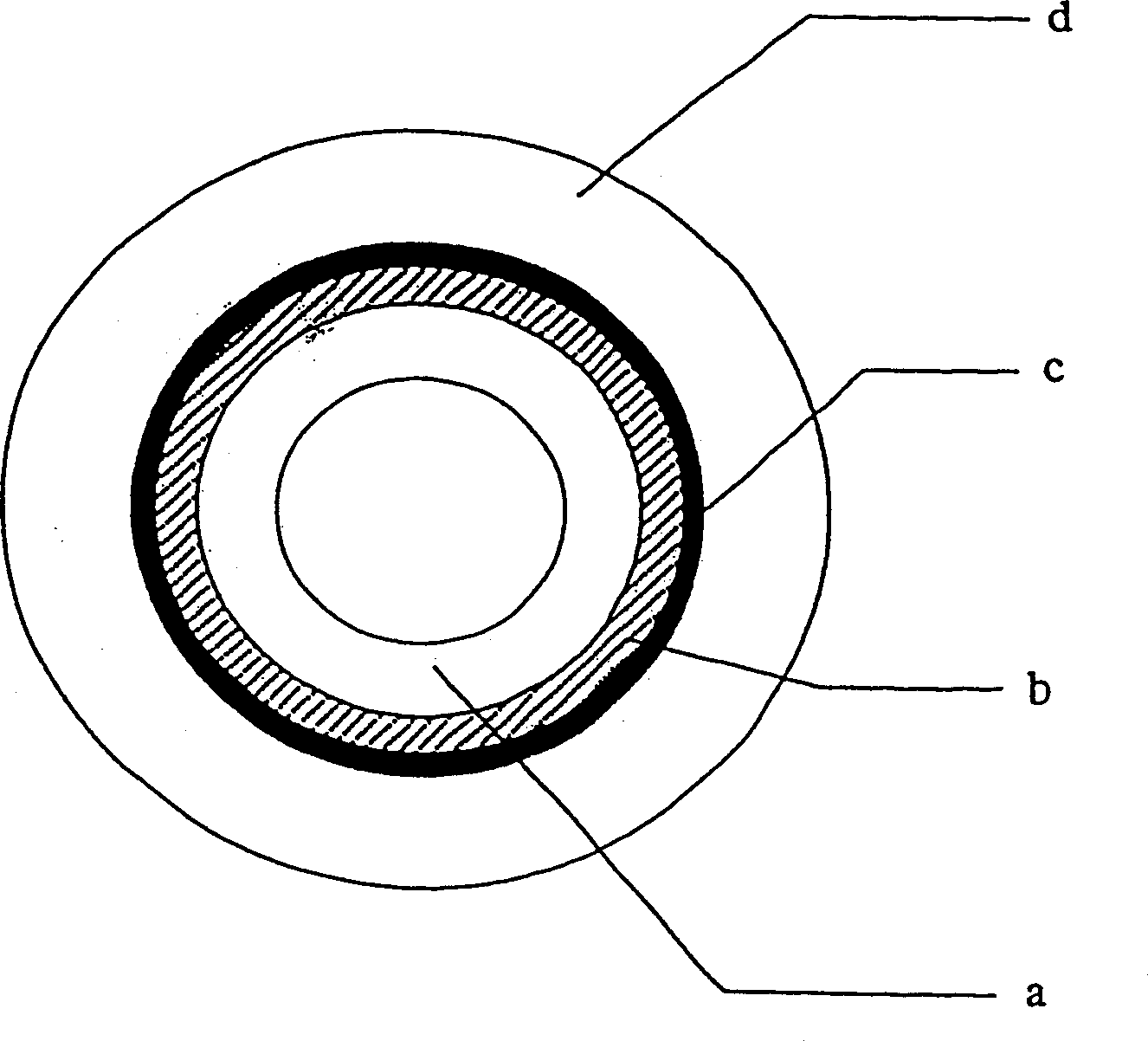

[0055] Typically, fuel pipes for automobiles have dimensions of 8 x 1 mm, ie an outer diameter of 8 mm and a wall thickness of 1 mm. A preferred fuel line according to the invention is constructed, for example, as follows, but is not limited to this structure:

[0056] a: inner layer consisting of polyamide 6-based molding compound; 0.2-0.7 mm thick;

[0057] b: barrier and dissolution inhibiting layer consisting of a molding compound based on ethylene / vinyl alcohol copolymer; 0.1-0.3 mm thick,

[0058] c: Adhesion-promoting interlayer of molding compounds based on polyamides selected from copolyamide 6 / 12, block copolyamide 6 / 12, polyamide 612, polyamide 6 and blends of polyamide 12 with compatibilizer, and polyamide 610; 0.05-0.2 mm thick,

[0059] d: Outer layer consisting of polyamide 12-based molding compound; 0.2-0.7 mm thick.

[0060] When varying individual layer thicknesses in practice, care is generally taken to achieve total wall thicknesses of about 1 mm or slig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com