Expansion tobacco chemical additives and preparation process and application thereof

A technology of chemical additives and tobacco, which is applied in the fields of tobacco, application, and treatment of tobacco, and can solve problems such as heavy burnt gas, lack of richness, and light smoke flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

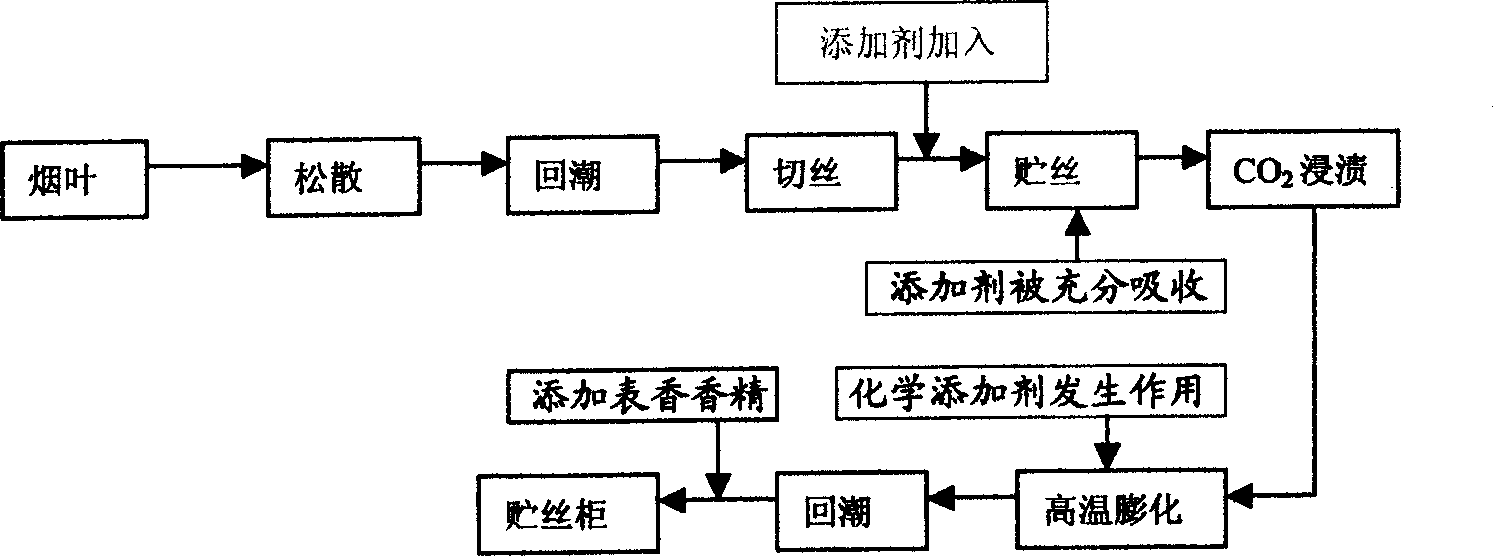

Method used

Image

Examples

Embodiment 1

[0033] Glucosylamine 0.1%

[0034] Amino Acid 0.1%

[0035] Weak ammonium salt 0.2%

[0036] Ammonia 1%

[0037] Organic amine 0.1%

[0038] Dicarbonyl organocatalyst 0.01%

[0039] Tobacco leaf hydrolysis reaction material 0.5%

[0040] Polyol 5%

[0041] Fruit reducing sugars 1%

[0042] Water add up to 100%

Embodiment 2

[0044] Glucosylamine 5%

[0045] Amino acids 8%

[0046] Weak ammonium salt 10%

[0047] Ammonia 15%

[0048] Organic amines 10%

[0049] Dicarbonyl organocatalyst 1%

[0050] Tobacco leaf hydrolysis reaction material 0.5-10%

[0051] Polyol 30%

[0052] Fruit reducing sugars 15%

[0053] Water add up to 100%

Embodiment 3

[0055] Glucosylamine 3%

[0056] Amino Acid 5%

[0057] Weak ammonium salt 8%

[0058] Ammonia 10%

[0059] Organic amine 5%

[0060] Dicarbonyl organocatalyst 0.5%

[0061] Tobacco leaf hydrolysis reaction material 5%

[0062] Propylene Glycol 15%

[0063] Fruit reducing sugars 8%

[0064] Water add up to 100%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com