Liquoride sugar and production method thereof

A production method, the technology of licorice sugar, which is applied in the direction of purification with adsorbents, can solve the problems of odor, low saponin content, and many impurities, and achieve the effect of scientific material selection, simple production method, and bright color

Inactive Publication Date: 2002-10-02

王维新 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

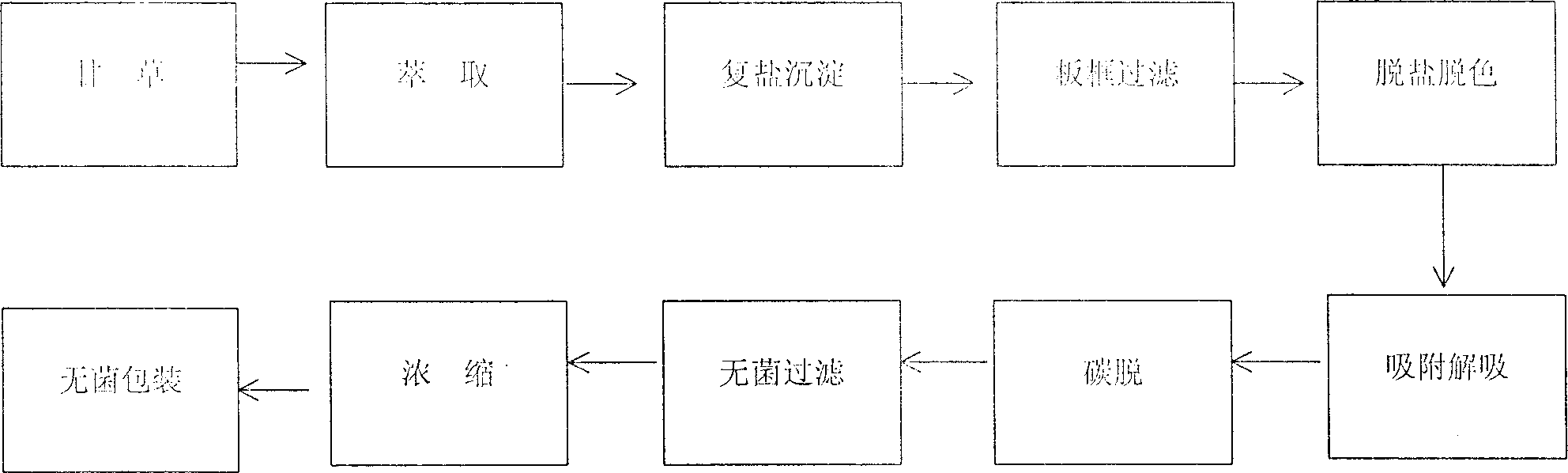

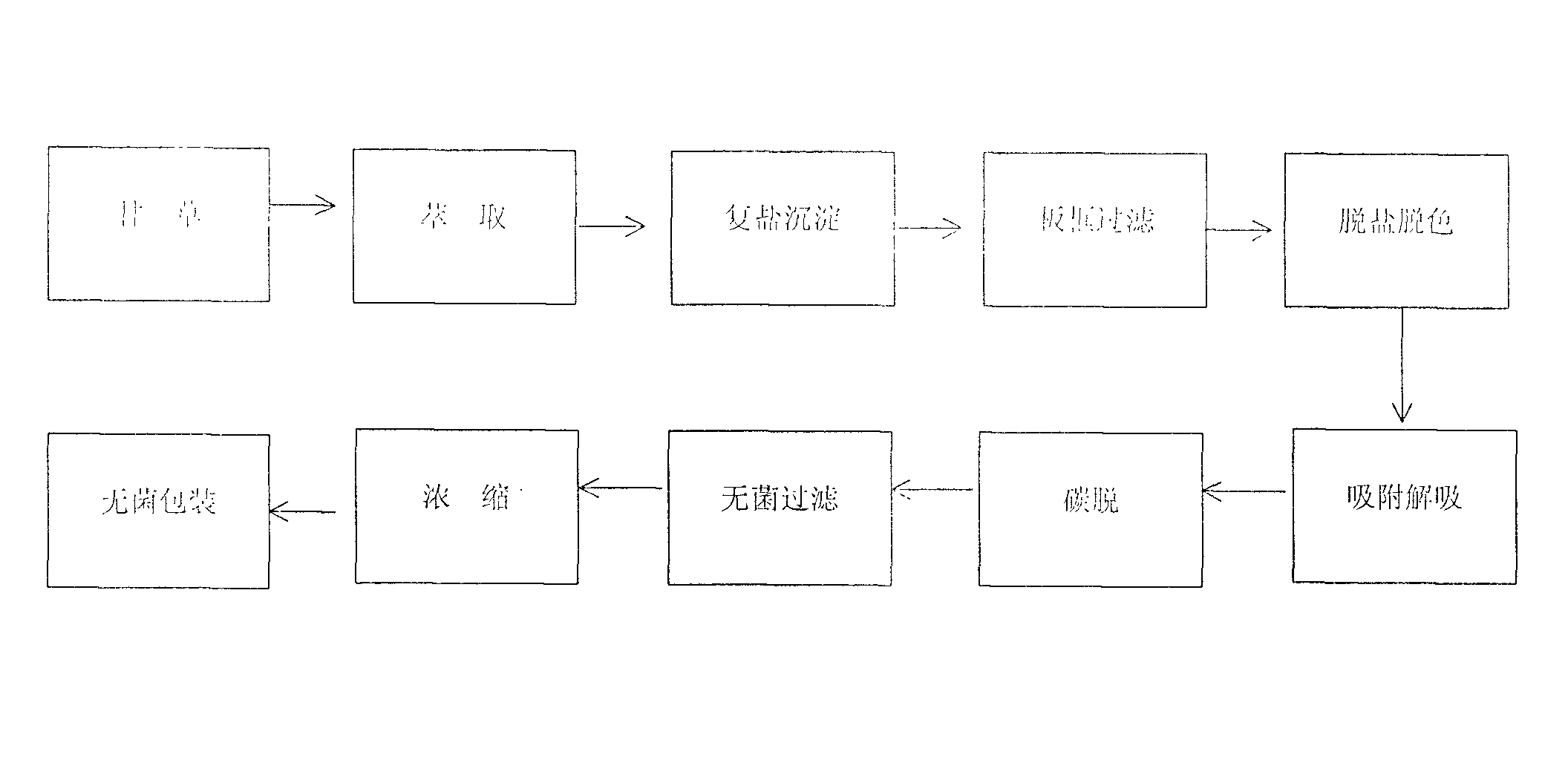

[0002] At present, the existing licorice candy is formed by soaking and extracting the extract, sedimentation, filtration, concentration and drying. The saponin content is low, only about 35%, and there are many impurities and peculiar smell. insufficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] The raw materials of the present invention include: 100kg of licorice, 300kg of deionized water, 2kg of ferric chloride, 2kg of calcium hydroxide, 1000kg of resin, 2000kg of edible ethanol and 1000kg of activated carbon. Production method of the present invention is the same as above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The production method of licorice saccharide is characterized by that its raw material includes licorice, deionized water, ion trichloride, calcium hydroxide, double salt, resin and active carbon, itcan be directly used as food additive, and its wseetness can be up to 100 tiems that of cane sugar, and its total saponin content is up to above 95%.

Description

1. Technical field [0001] The invention relates to a food additive and a medical additive, in particular to a licorice candy and a production method thereof. 2. Background technology [0002] At present, the existing licorice candy is formed by soaking and extracting the extract, precipitation, filtration, concentration and drying. The saponin content is low, only about 35%, and there are many impurities and peculiar smell. insufficient. 3. Contents of the invention [0003] The object of the present invention is to invent a kind of licorice candy and its production method. The licorice candy produced by this production method has high purity, no peculiar smell, wide application range, and can increase the total saponin content to reach the hygienic index of western medicine auxiliary materials. [0004] The object of the present invention can be achieved through the following embodiments: the raw material of the present invention comprises: Radix Glycyrrhizae 80~100kg, d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C13B20/12

Inventor 王维新苗文忠

Owner 王维新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com