Chip heat sink package structure and making method thereof

A packaging structure and chip heat dissipation technology, which is applied in the direction of cooling/ventilation/heating transformation, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reduced heat dissipation effect, increasing the gap between the supporter and the die, and difficulty in implementation. To achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

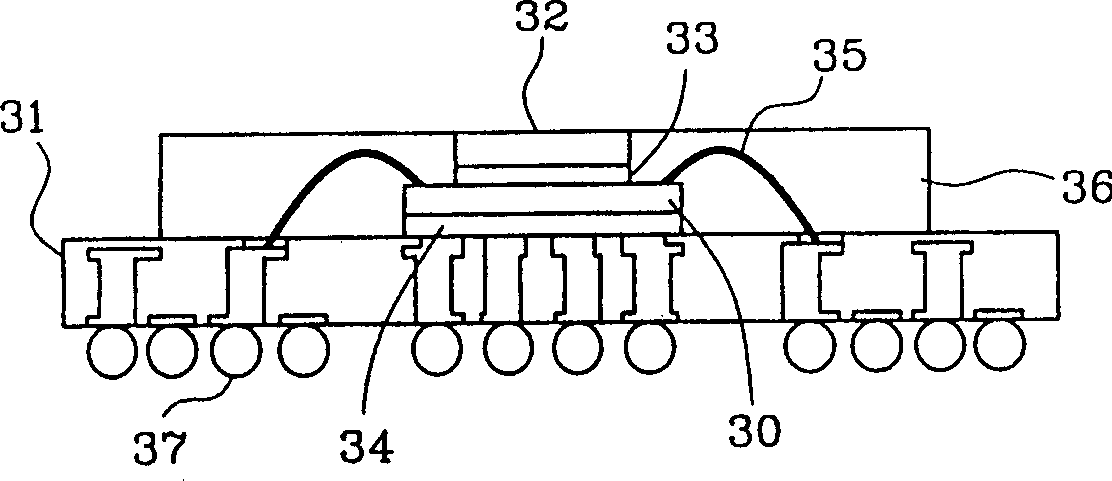

[0038] image 3 Shown is a schematic cross-sectional view of the structure of the first embodiment of the present invention. The chip heat dissipation packaging structure of the present invention is to improve the ability of the chip to dissipate heat through the setting of a heat sink 32 in a chip package. It includes: a substrate 31, by The substrate 31 carries a die 30 cut from a wafer, and the die 30 is pasted on the proper position of the substrate 31 through a second thermally conductive adhesive 34 of a suitable material between the die 30 and the substrate 31, and then after a period of time The second heat-conducting adhesive 34 is cured so that the die 30 can be fixed at an appropriate position on the substrate 31; afterward, the signal input and output terminals on the die 30 are connected to the appropriate contacts on the substrate 31 by wires 35 of appropriate materials ; This tube core 30 is the core of semiconductor work. When performing calculation processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com