Enzyme-removing degumming process of preparing rutin

A new process, the technology of rutin, is applied in the field of rutin prepared by the new process of enzyme elimination and glue removal, which can solve the problems of enzyme elimination and glue removal methods that have not been introduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

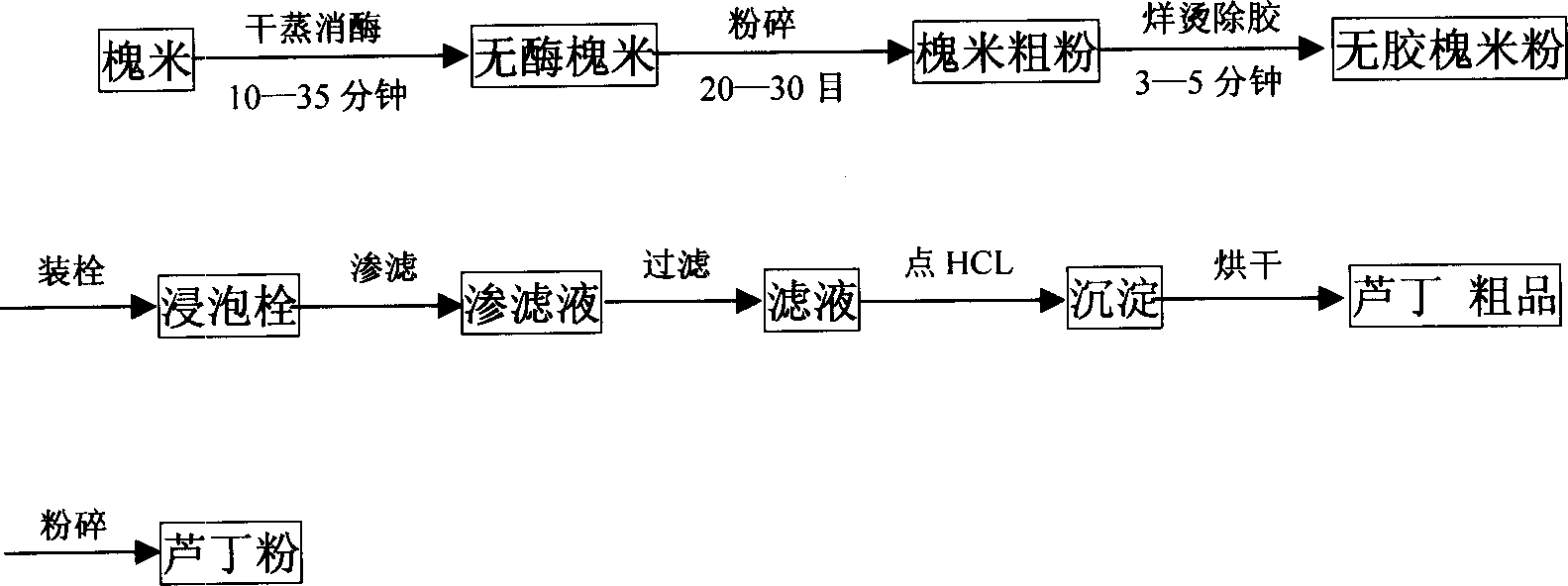

[0008] Embodiment 1: use dry steaming method in airtight container and under the temperature of 65 ℃, carry out 10 minutes dry steaming enzyme-removing treatment to the finished Sophora japonica of airing, be pulverized into 20-30 purpose coarse powder, then in After 3 minutes of blanching and filtering in 80°C water to remove impurities such as pectin and pigments, then according to the current process, perform plugging, percolation, filtration, HCL pointing, drying and crushing to obtain the purity rate and extraction The rate is better than the rutin powder product of the current technology.

Embodiment 2

[0009] Embodiment 2: use dry steaming method in airtight container and under the temperature of 85 ℃, after carrying out 35 minutes dry steaming enzyme-eliminating treatment to the finished Sophora japonica of airing, it is pulverized into 20-30 purpose coarse powder, then in After 5 minutes of blanching and filtering in 90°C water to remove impurities such as pectin and pigments, then according to the current process, perform plugging, percolation, filtration, HCL pointing, drying and crushing to obtain the purity rate and extraction The rate is higher and is better than the rutin powder products of the current technology.

Embodiment 3

[0010] Embodiment 3: use dry steaming method in airtight container and under the temperature of 100 ℃, after carrying out 25 minutes dry steaming enzyme-eliminating treatment to the finished Sophora japonica of airing, it is pulverized into 20-30 purpose coarse powder, then in After 4 minutes of blanching and filtering in 100°C water to remove impurities such as pectin and pigments, then according to the current process, perform embolization, percolation, filtration, pointing of HCL, drying and crushing to obtain high purity and extraction. High rate rutin powder products.

[0011] In conjunction with the foregoing embodiments, it can be seen that the present invention has the following advantages compared to the prior art:

[0012] 1. Adopting the new process to prepare rutin, the extraction rate is high, the cost is low, the cycle is short, and the purity is good;

[0013] 2. Reduce the consumption of Huai Mi and make full use of this scarce natural resource;

[0014] 3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com