Metal in-situ statistical-distribution analysis method

A technology of statistical distribution and analysis method, which is applied in the field of material analysis, can solve the problems of unable to analyze the distribution of elements and inclusions, unable to record the position of a single discharge, unable to observe abnormal sparks, etc., to avoid errors, strong practicability, Quantitatively Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

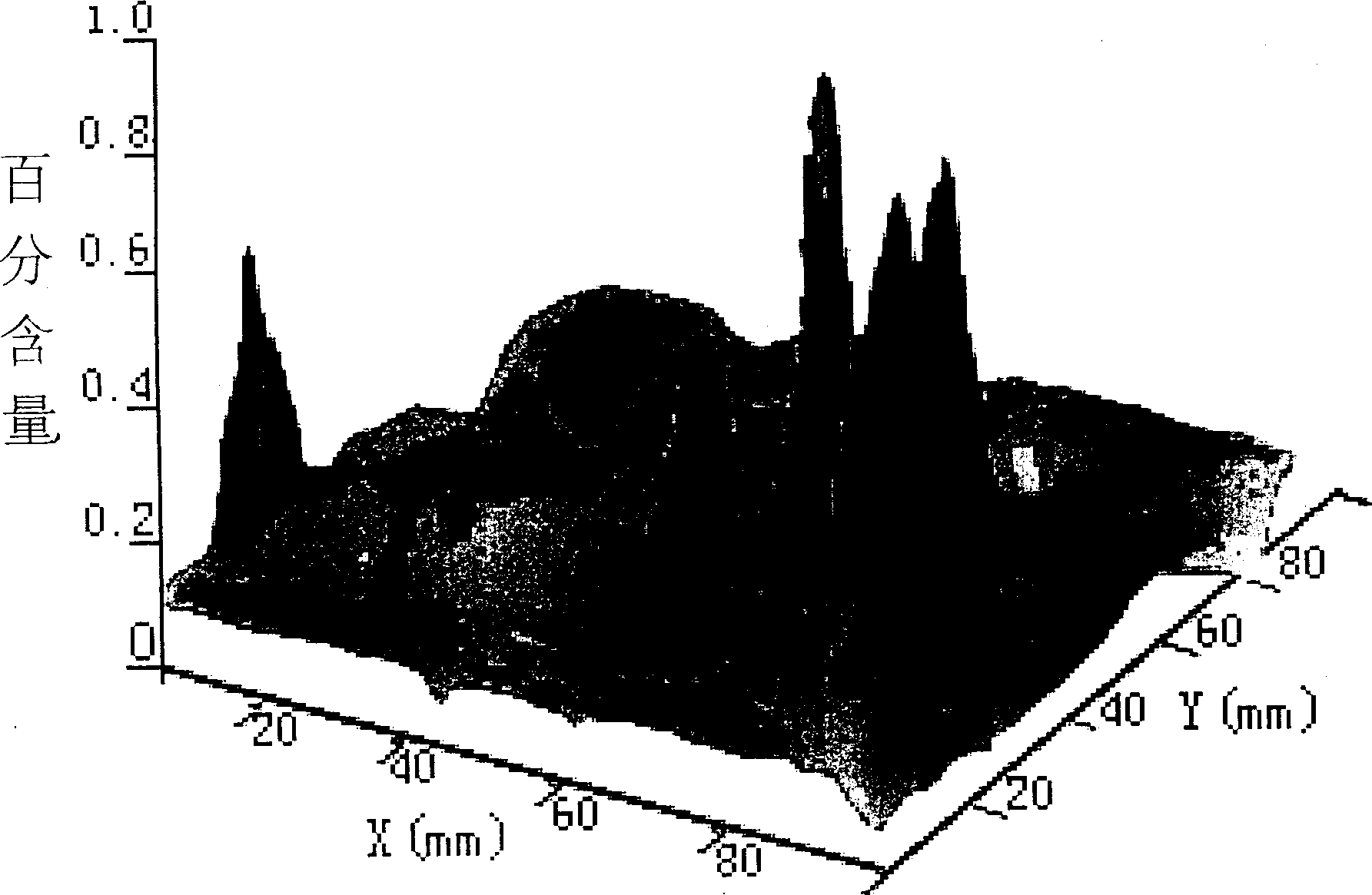

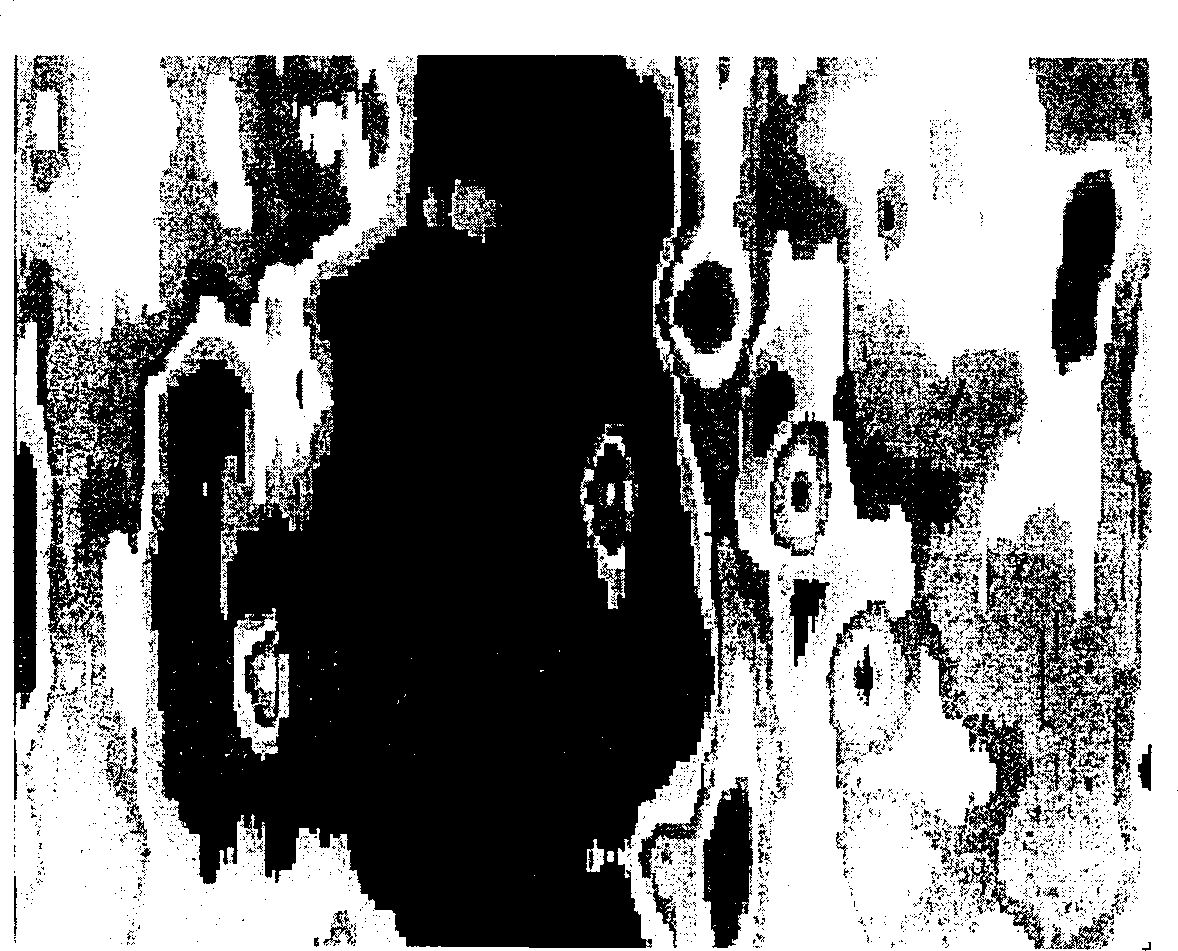

[0041] The chemical composition, segregation degree, porosity and inclusion distribution of the three samples are analyzed by using the metal in-situ statistical distribution analysis method of the present invention.

[0042] The three samples are as follows: sample A is ordinary carbon continuous casting slab, in which A1 is the continuous casting slab that has been lightly pressed by rolls after it leaves the continuous casting machine, and A2 is the casting slab that has not been lightly pressed; sample B is a billet of 20MnSi; sample C is a low carbon steel weld metal for ships. Table 1 lists the designed chemical composition of samples A and B steel types during smelting, and sample C is the designed chemical composition of the base metal during smelting.

[0043] The sample is cut from the sample, and the sample is processed into a plane, and a fresh surface is ground with sandpaper or a grinder. The sample is clamped in a continuous excitation synchronous scanning posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com