Electromagnetic rope clutch

A clutch and electromagnetic technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of low force chain strength, increased use, easy aging of magnetic powder, etc., to achieve large transmission torque, small size and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

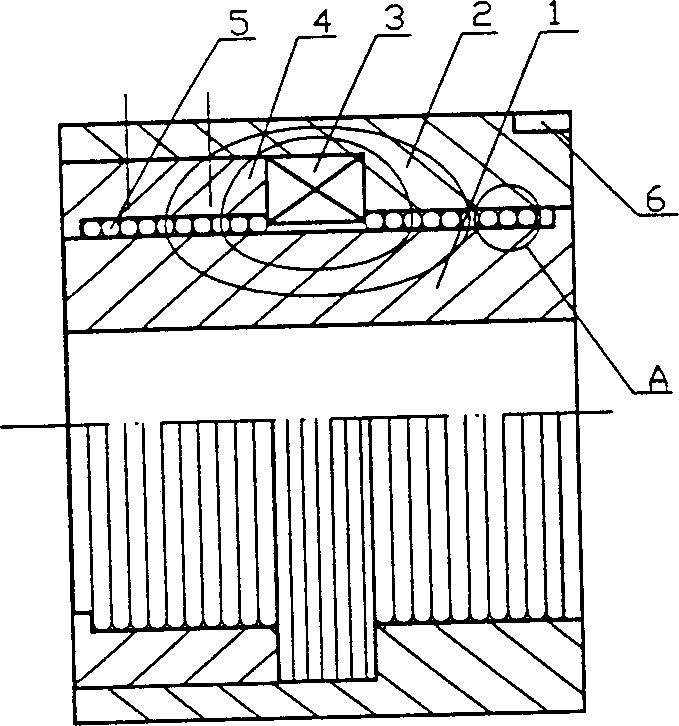

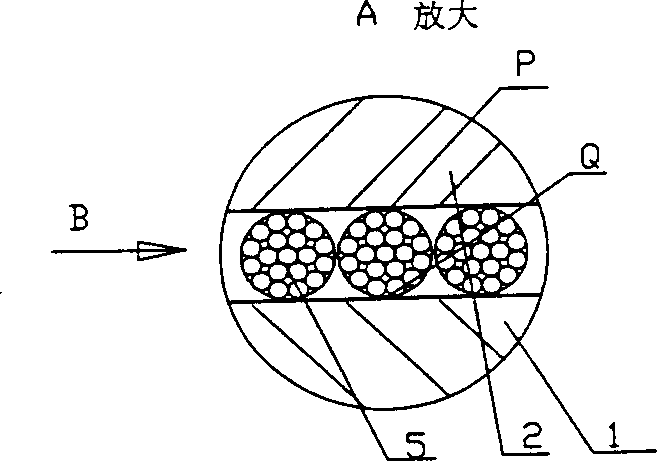

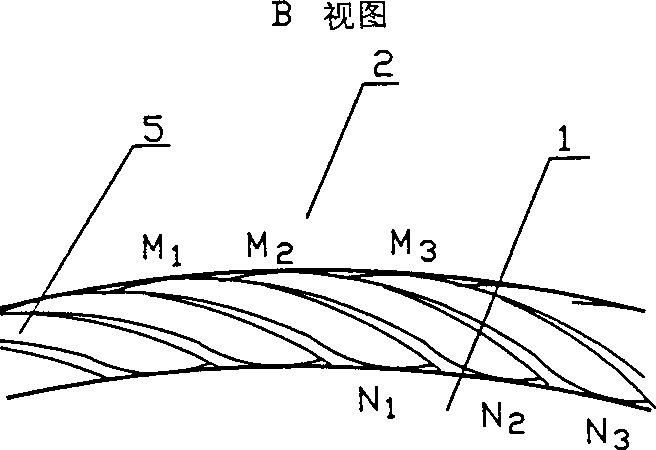

[0014] figure 1 In the given embodiment, the driving shaft and the driven sleeve are used. In this embodiment, since there is a certain gap between the steel wire rope 5 and the outer cylindrical surface of the driving shaft 1, the two do not contact; But the positive pressure is only the weight of the steel wire rope, so the friction is very small. When the driving shaft 1 rotates, the driven sleeve 2 does not rotate; when the coil is energized, an elliptical magnetic force line is formed around the coil, and the magnetic force deforms the end surface of the steel wire rope 5. , which is close to the outer edge of the driven sleeve 2 and is adsorbed on the inner wall of the sleeve, such as figure 2 As shown by the P point of , the inner edge part near the drive shaft is adsorbed on the outer cylindrical surface of the drive shaft, such as figure 2 As shown by the point Q in the figure; the magnetic line of force goes from the yoke (that is, sleeve 2) through point P of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com