Silver halide emulsion and silver halide photography photosensitive material

A silver halide and emulsion technology, applied in the field of silver halide photographic photosensitive materials, can solve the problems of inappropriate high sensitivity and blurred images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below.

[0043] The silver halide emulsion of the present invention contains specific silver halide particles. The particle shape of the particles is not particularly limited, but it is preferably made of cubic or 14-hedral crystal particles with {100} planes (the apexes of these particles are spherical or higher-order planes) or octahedral crystal particles, or It is formed of flat particles with an aspect ratio of 2 or more formed by {100} planes or {111} planes with a total projected area of 50% or more. The so-called aspect ratio is a value obtained by dividing the diameter of a circle corresponding to the projected area by the particle thickness. In the present invention, it is more preferably a cubic or 14-sided particle.

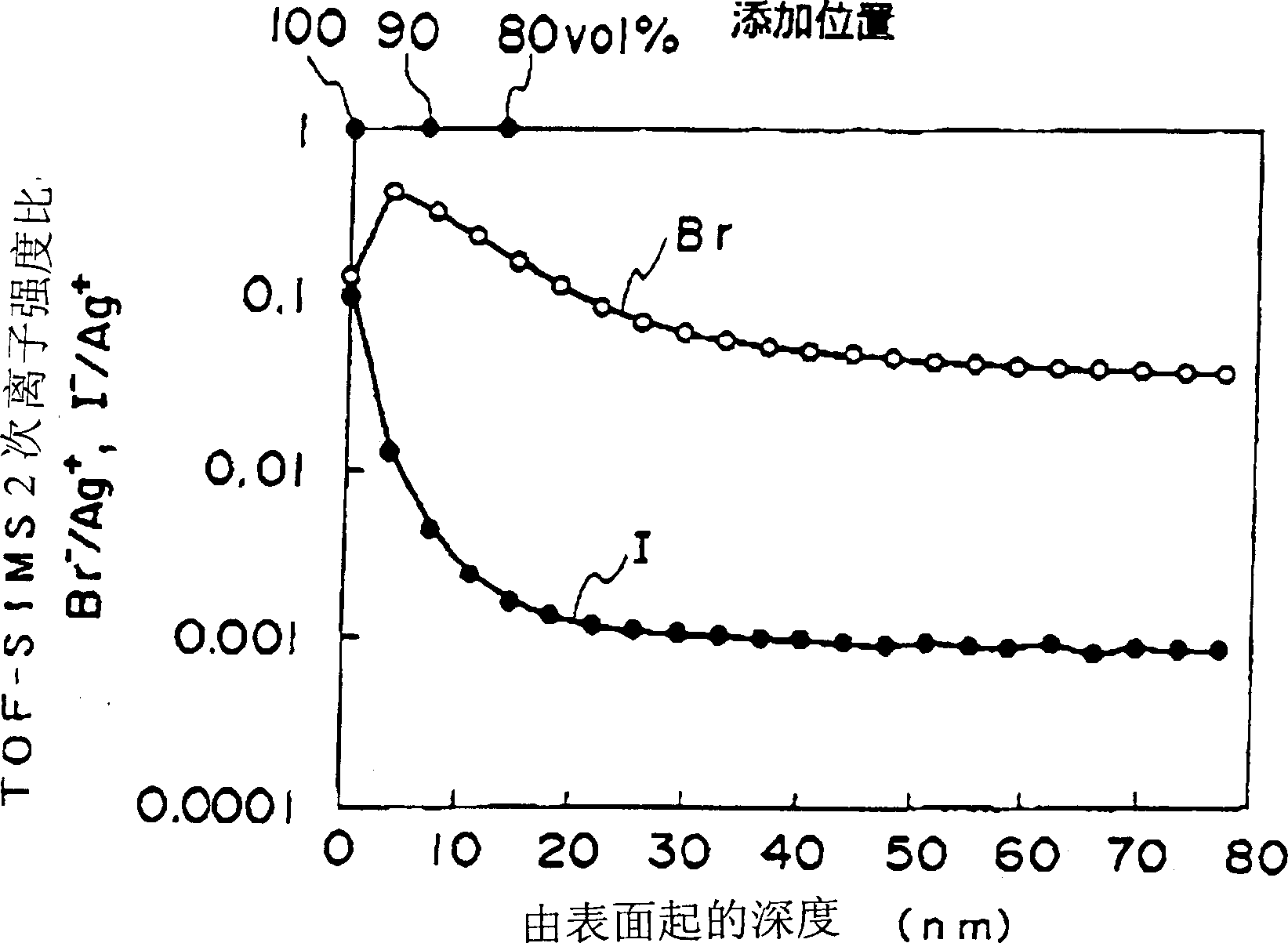

[0044] As the silver halide emulsion of the present invention, an emulsion containing specific silver halide particles is used. The silver chloride content must be 90 mol% or more. From the viewpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com