Electric actuating device

An actuating device, electric technology, applied in the direction of electromechanical devices, transmission devices, electric components, etc., can solve the problem of high cost, achieve the effect of simplifying the structure, reducing the driving force requirements, and reducing the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings. Here, parts that are the same as or equivalent to those in the prior art are denoted by the same symbols, and detailed description thereof will be omitted.

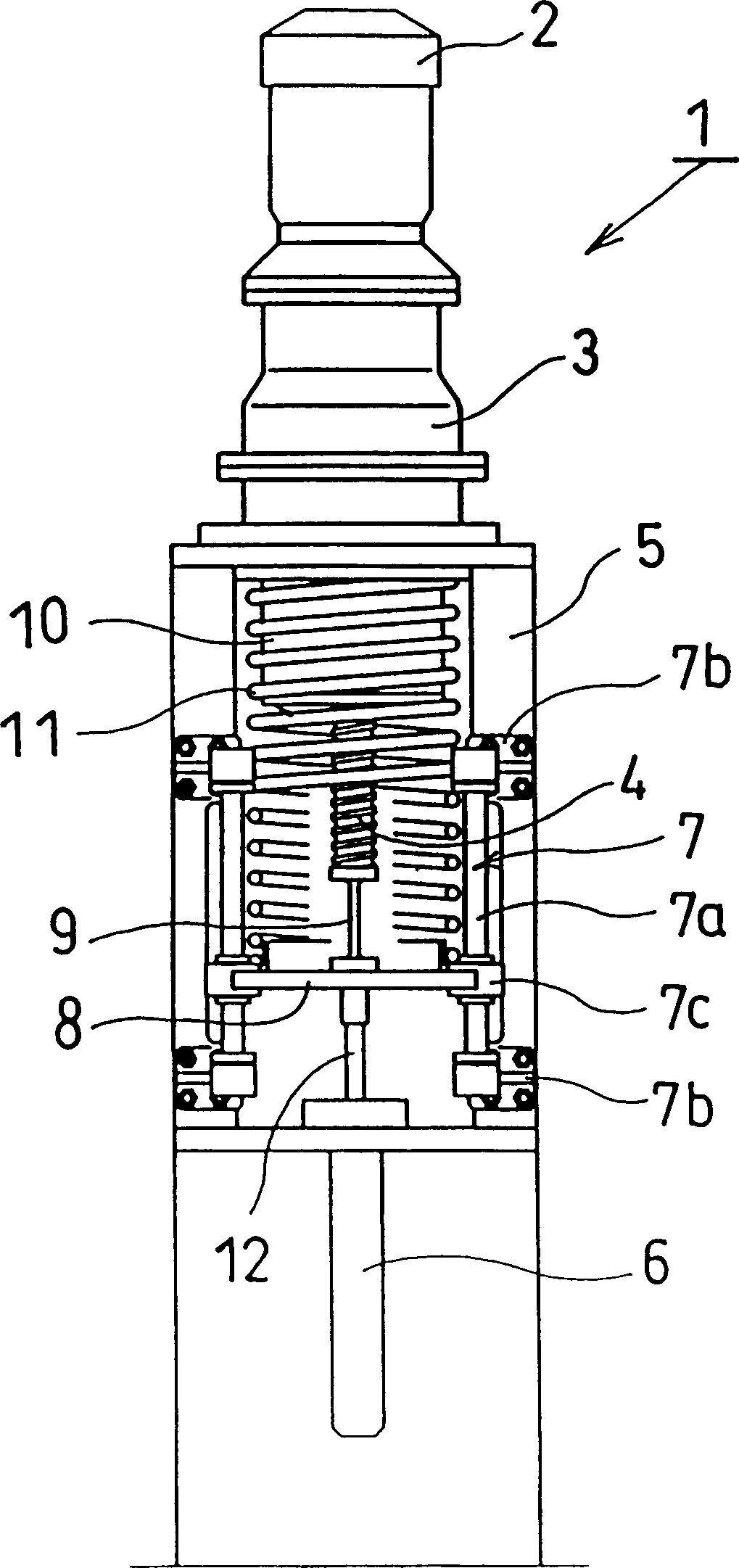

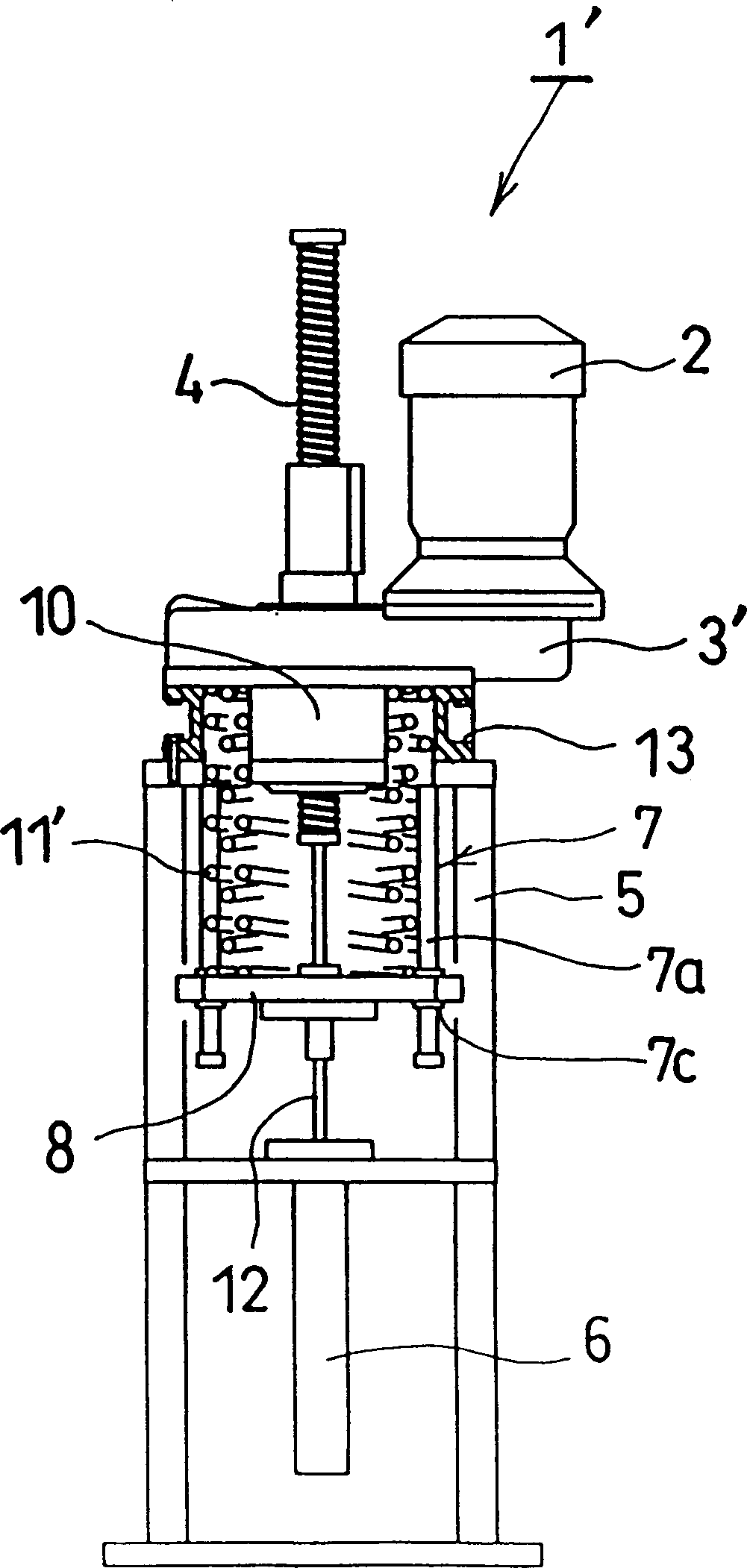

[0038] figure 1 A linear actuator 1 relating to an embodiment of the present invention is shown, which is used as a cylinder (injection cylinder) of an injection molding machine, and a driving device for a plunger pump (hereinafter referred to as a pressurization cylinder). In this linear actuator 1, as the reducer 3, a reducer such as a planetary gear reducer whose input shaft and output shaft are on the same axis is used, and the axes of the motor 2, the reducer 3, and the screw 4 are all arranged in a straight line superior. Moreover, the rotating shaft of the motor 2 and the rotating shaft of the reducer 3 are set as hollow shafts, and the screw 4 passing through the hollow shafts is moved in the axial direction (the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap