Refrigerating method and refrigerator

A refrigeration method and refrigerator technology, applied in refrigerators, refrigeration and liquefaction, adsorption machines, etc., can solve the problems of large cooling water circulation, high vacuum degree requirements, high heat generation, etc., and achieve a reasonable and good heat exchange process Environmentally friendly, economical effect of cooling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

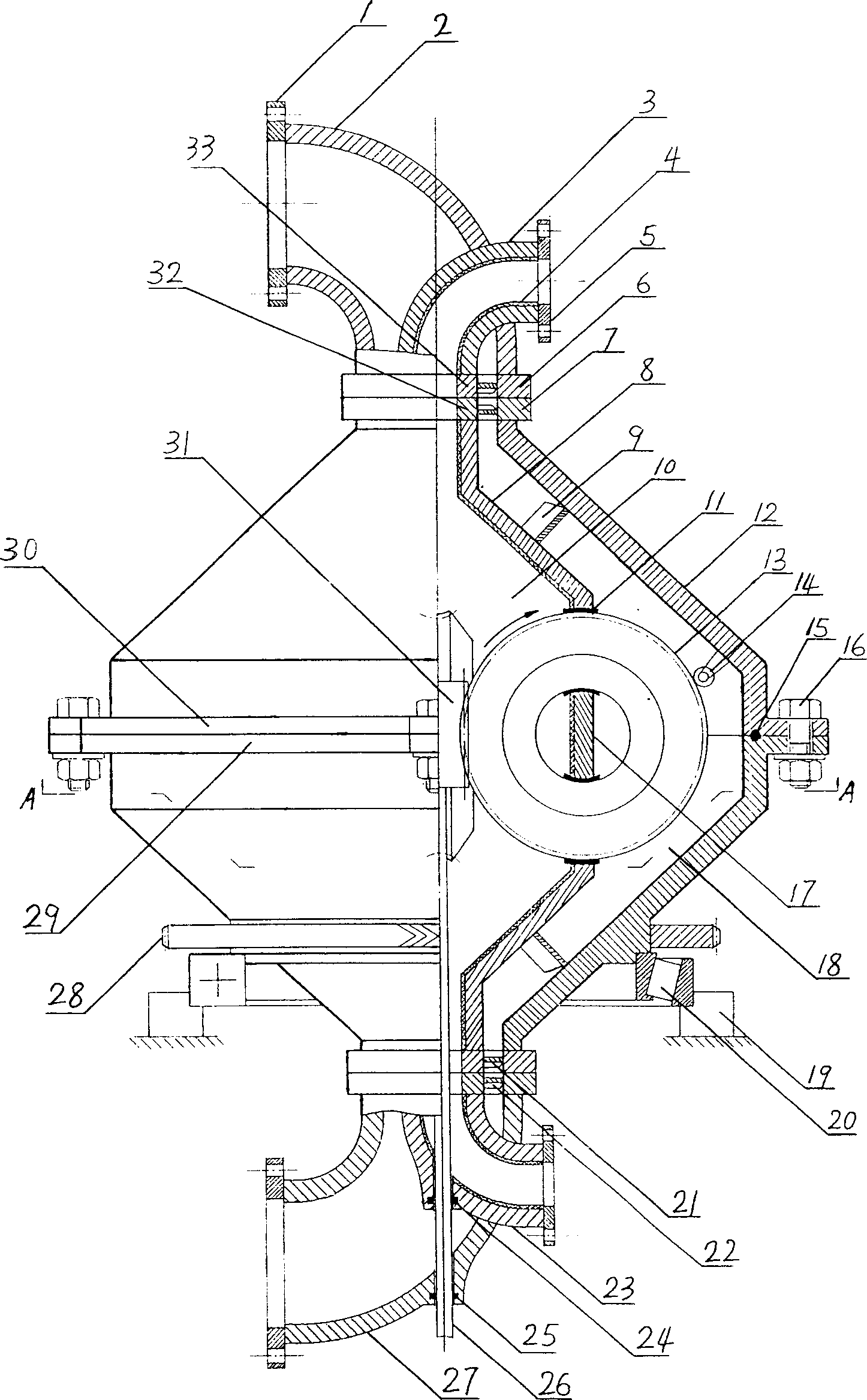

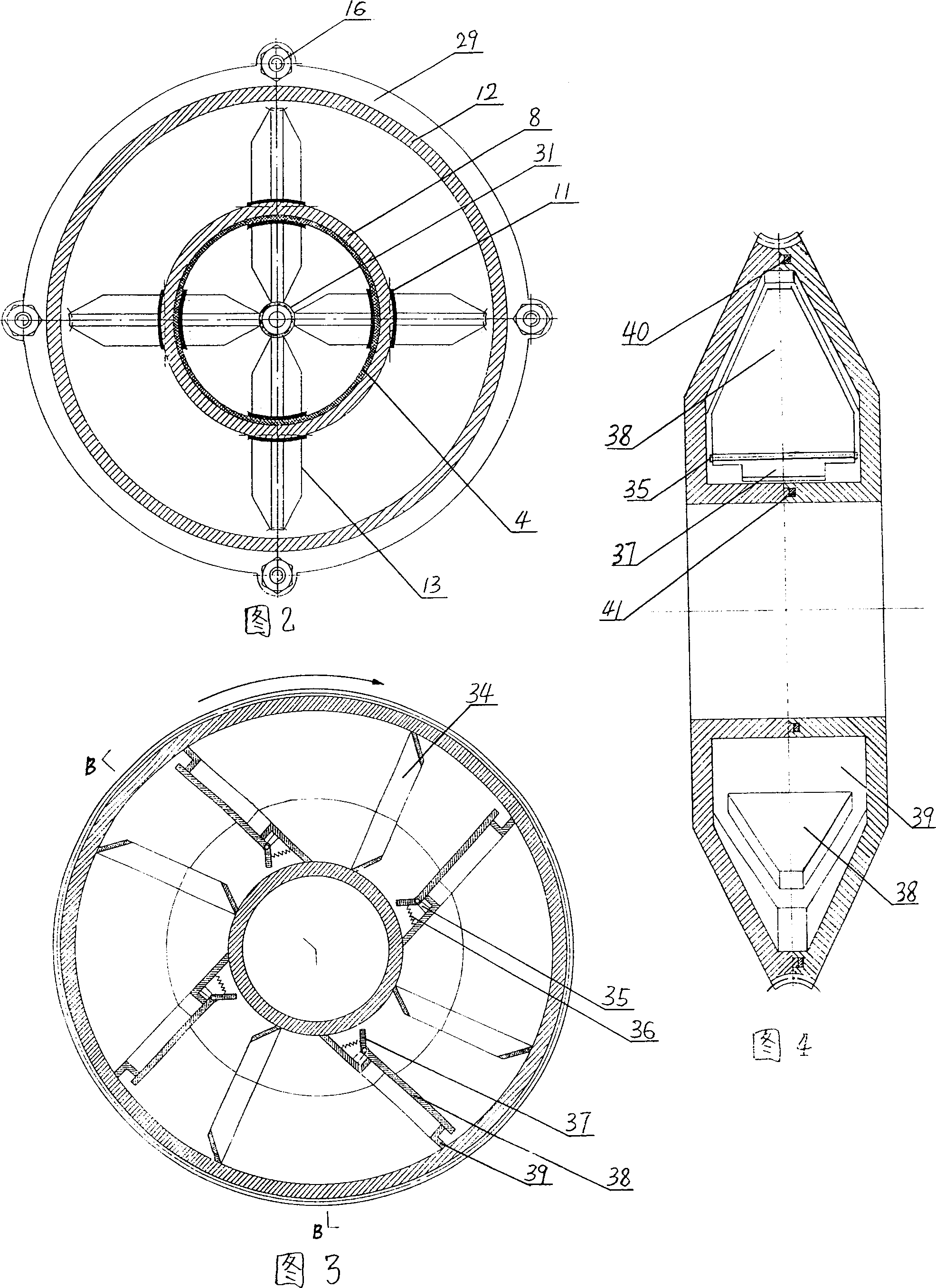

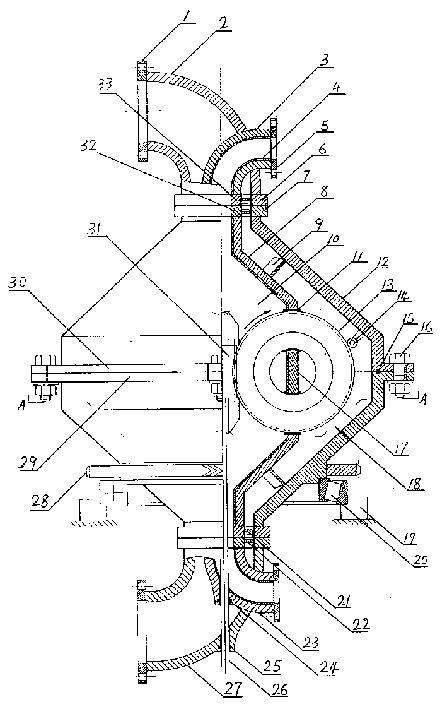

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The invention is a rotary refrigeration method, which includes the evaporation and condensation process of the refrigerant, the evaporation process is a periodic evacuation and vaporization process, and the condensation process is a direct cooling process of the refrigerant vapor to the liquid refrigerant The process of compression and liquefaction; these two processes are formed when the refrigeration container 13 is doing revolution and rotation. In order to implement the above-mentioned refrigeration method, the present invention provides two kinds of rotary refrigerators with a three-dimensional rotary system and a one-dimensional rotary system, and this embodiment provides a rotary refrigerator with a three-dimensional rotary system.

[0024] The structure of the present invention is as figure 1 Shown: including power, evaporating and conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com