Fast detector for milk component

A component detection and detection instrument technology, which is applied in the direction of instruments, food testing, and analysis materials, etc., can solve the problems that cannot meet the needs of rapid detection of milk components, lack of on-site use and manual adjustment, and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

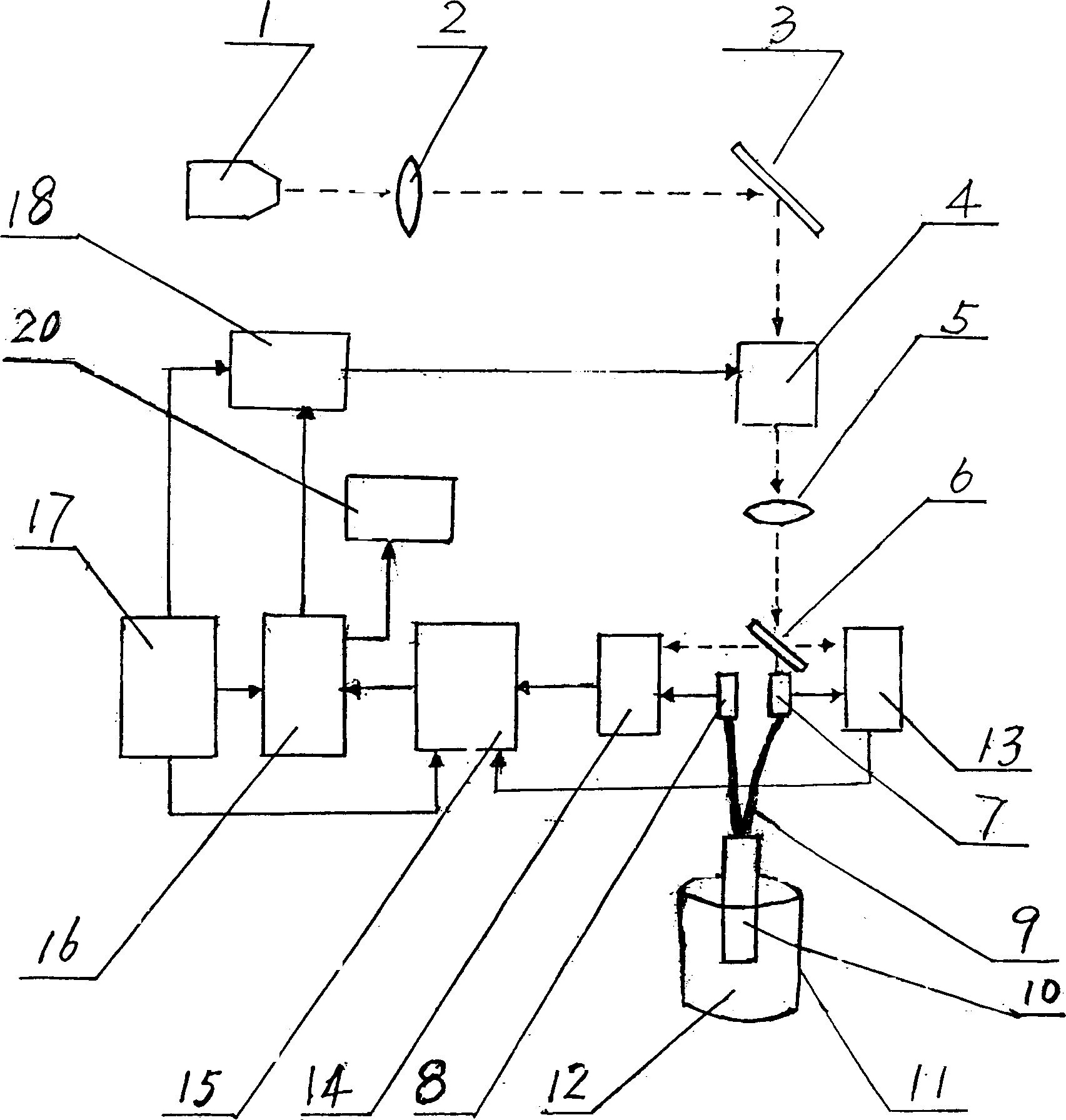

[0033] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

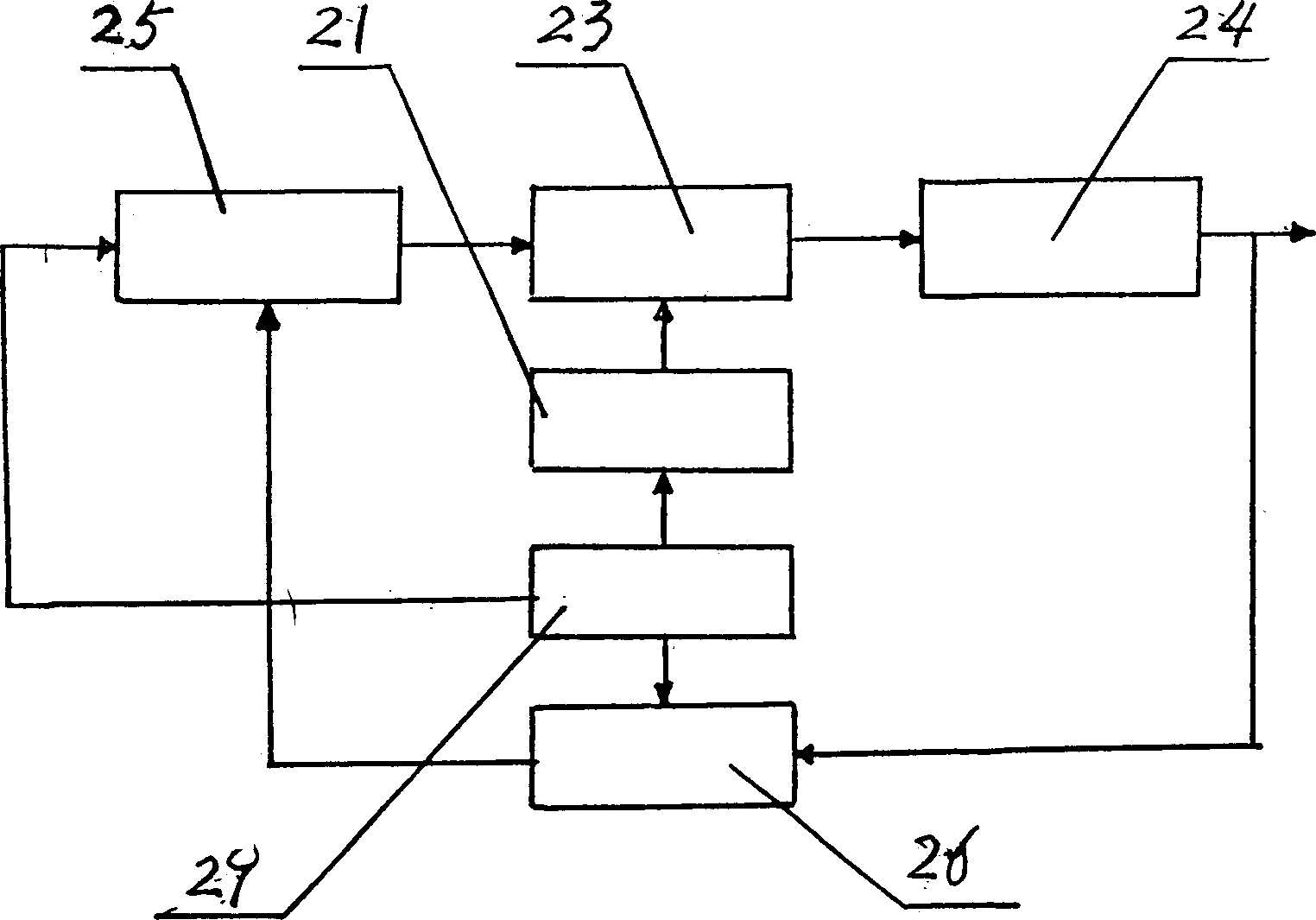

[0034] exist figure 1 Among them, the intelligent phase-locked loop loop that is provided with in the driver 18 is made up of adder 23, D / A converter 21, microprocessor 29, phase-detection low-pass filter 25, dividing N frequency division controller 26, is used for milk composition Quickly generate and output adjustable high-frequency electrical signals during detection. Its adder 23, D / A converter 21, microprocessor 29 are sequentially connected by conductor; The microprocessor 29 is also connected with the phase-detection low-pass filter 25 and the division-by-N controller 26 by conductors.

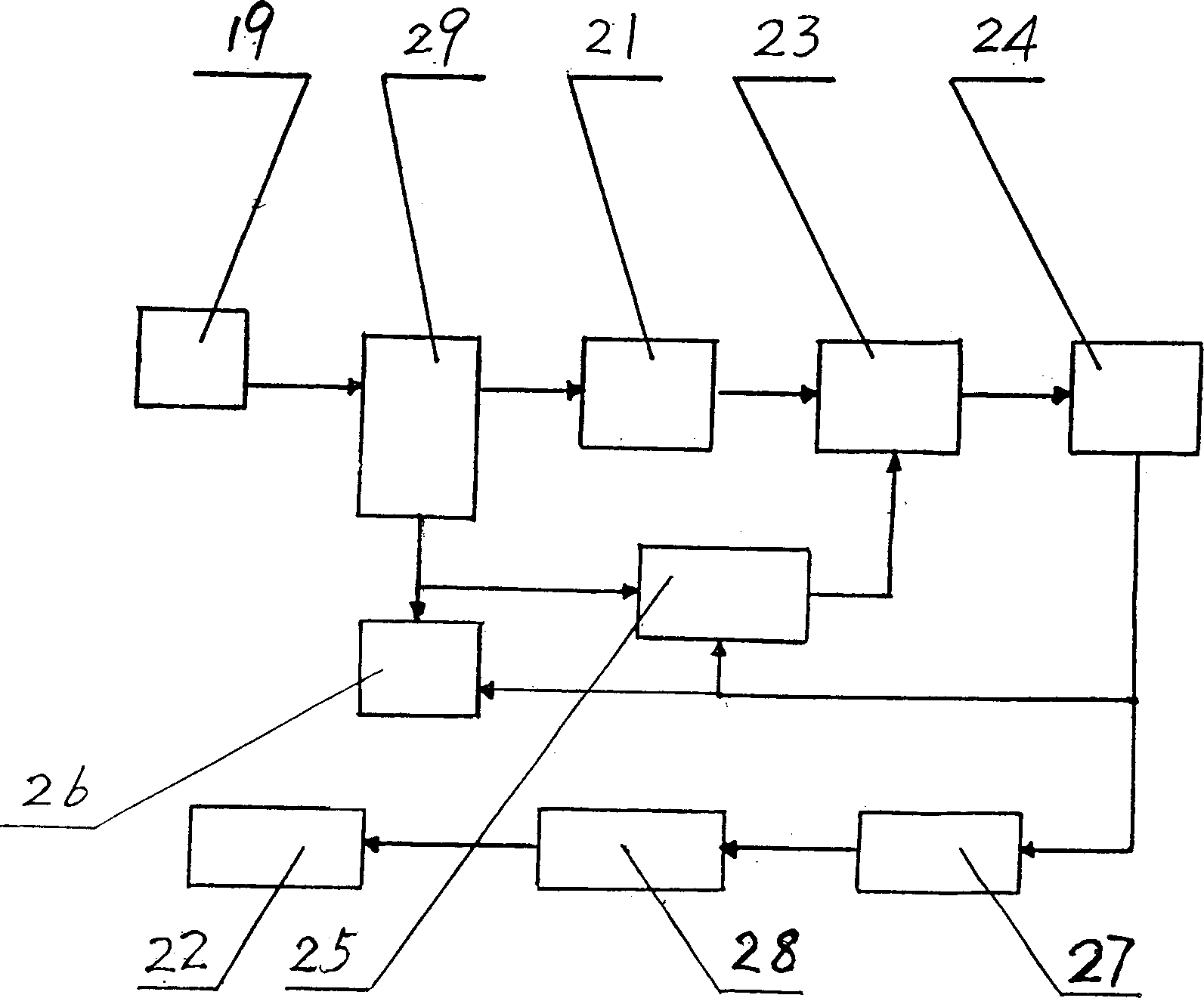

[0035] exist figure 2 Among them, the control circuit provided in the driver 18 is composed of an intelligent phase-locked loop loop circuit and a current power amplification output circuit connected by conductors.

[0036] Among them, the intelligent phase-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com