Power enlargement type apparatus for removing dust of ejecting drilling

A jet-suction drilling and power technology, applied in boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the problems of insufficient chip extraction force, DF system cannot replace gun drilling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

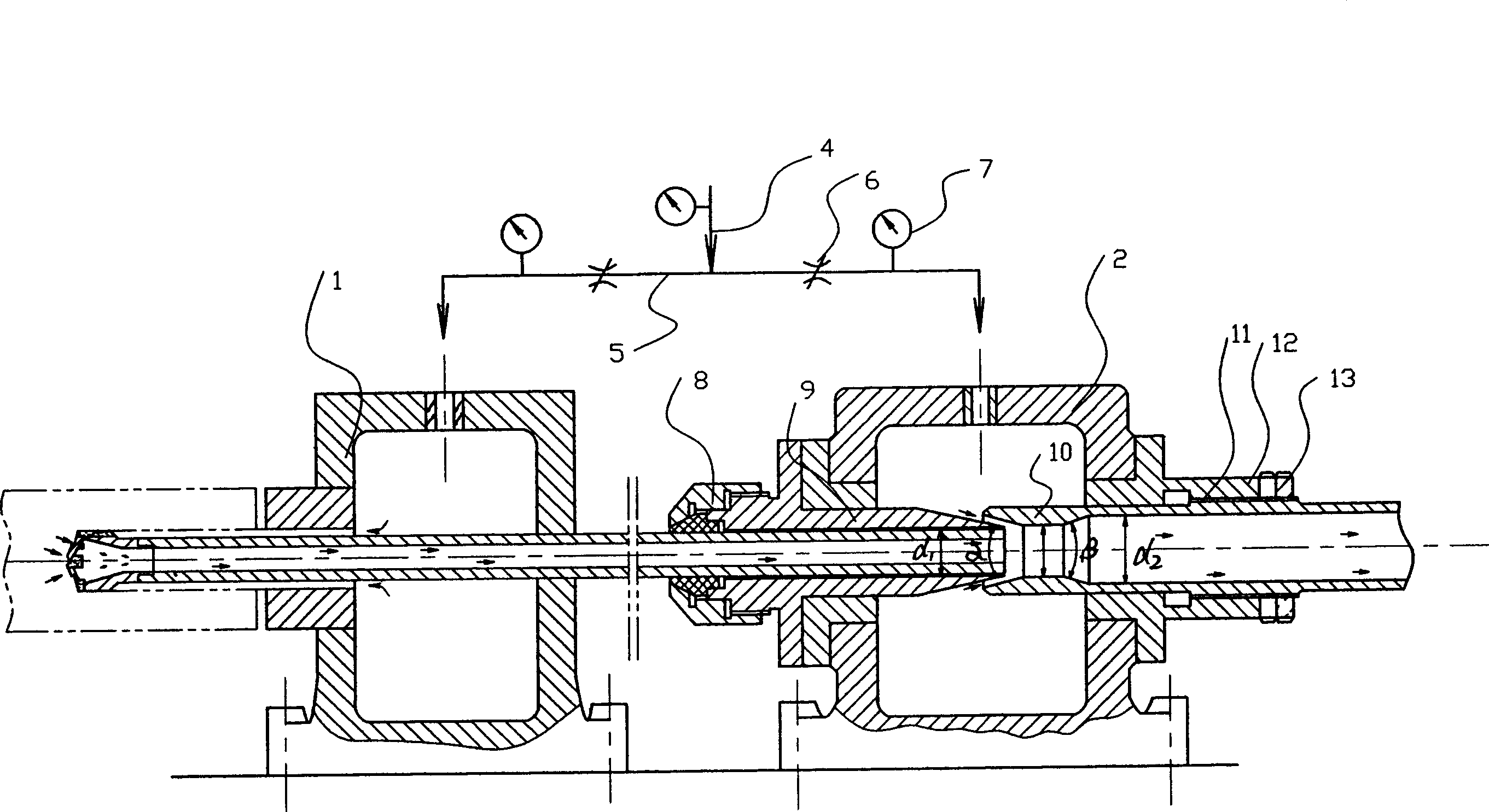

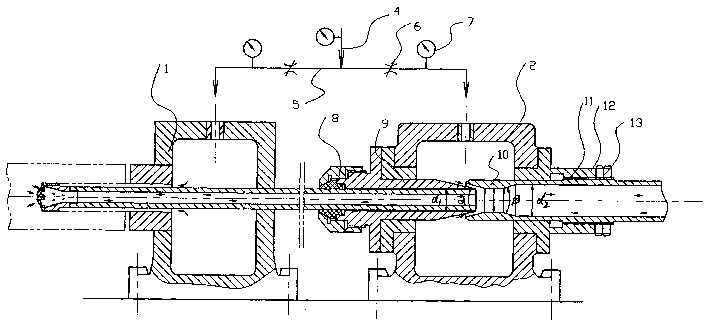

[0012] figure 1 Among them, the chip extraction device is mainly composed of an oil feeder 1 and a chip extractor 2. The structural feature is that the chip extractor 2 and the oil feeder 1 are connected to the main oil pipeline 4 on each branch oil pipeline 5. A fuel-saving valve 6 is installed in series, and a pressure gauge 7 is installed behind each fuel-saving valve 6, and a pressure gauge 7 is also equipped on the main oil pipeline, and the entire oil circuit is supplied with oil by an oil pump. The chip extractor 2 is composed of a sealed oil tank 8 and a front nozzle 9 and a rear nozzle 10 which are respectively sealed and assembled on the front wall and the rear wall of the sealed oil tank 8. The rear nozzle 10 is sealed by a sealing sleeve fixedly assembled on the rear wall of the sealed oil tank 8. Assembled in the sealing sleeve 12, the cylindrical surface of the front part of the rear nozzle 10 seals with the inner tube surface of the sealing sleeve 12 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com