A kind of automatic production process of battery box

A production process and battery box technology, which is applied in the field of automatic production process of battery boxes, can solve the problems of low production efficiency, unsound process, and poor reliability of battery boxes, and achieve the effects of improving efficiency, reliable quality, and reducing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

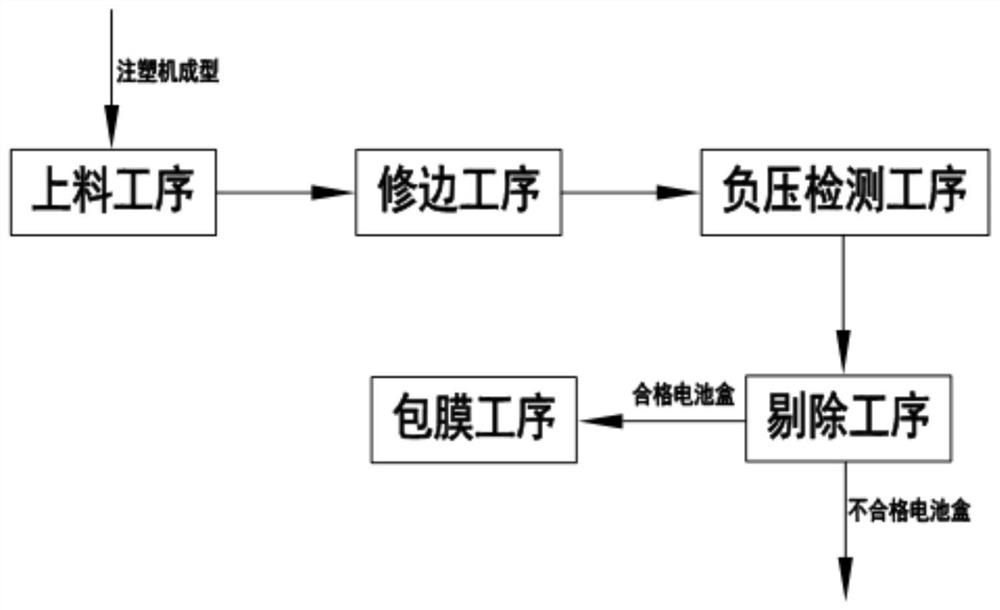

[0044] like figure 1 As shown, an automated production process for a battery box includes the following production process steps:

[0045] a. trimming process, the battery case 10 to be trimmed is placed on the positioning mechanism 41 positioned at the trimming station, and the cutter mechanism 42 positioned under the positioning mechanism 41 trims the upper end surface of the battery case 10. The support mechanism a43 located above the positioning mechanism 41 presses down the battery case 10 during the process of the side;

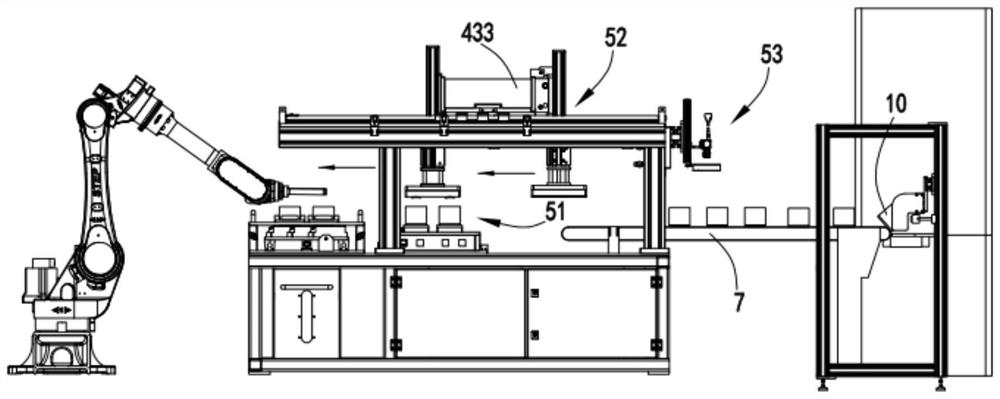

[0046] b. Negative pressure detection process, the battery case 10 that has been trimmed in step a is transferred to the negative pressure detection station under the drive of the support mechanism a43, and the first detection mechanism 51 located at the negative pressure detection station detects the battery Whether the box 10 has a gap;

[0047] c. Appearance inspection process, the battery box 10 that has completed the gap detection in the step b i...

Embodiment 2

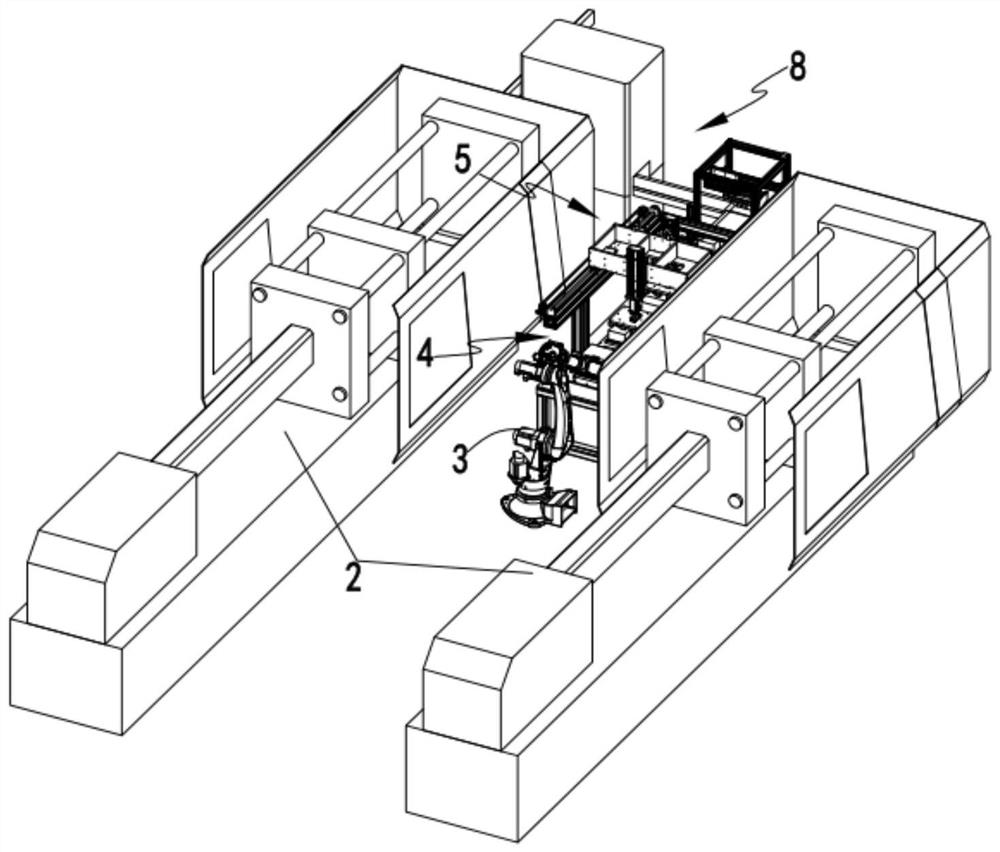

[0060] like Figure 2 to Figure 11 As shown, the present invention also provides an automatic battery box production system, which includes a support platform 1 and an injection molding machine 2 arranged on the side of the support platform 1. The front end of the support platform 1 is provided with a The manipulator 3 taken out of the battery case 10 is provided with a trimming device 4 , a detection device 5 and a rejecting device 6 sequentially on the support table 1 from front to back, and the trimming device 4 is used for removing the battery case 10 taken out by the manipulator 3 The upper end surface is trimmed, the detection device 5 is used to detect whether the battery case 10 is defective, and the rejecting device 6 is used to remove the defective battery case 10 detected by the detection device 5;

[0061] The trimming device 4 includes a positioning mechanism 41 for positioning the battery box 10, a cutter mechanism 42 arranged below the positioning mechanism 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com