LED epitaxial wafer electroluminescent nondestructive detection method

A technology of light-emitting diodes and detection methods, which is applied in the field of detection instruments and can solve problems such as destructiveness and non-continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

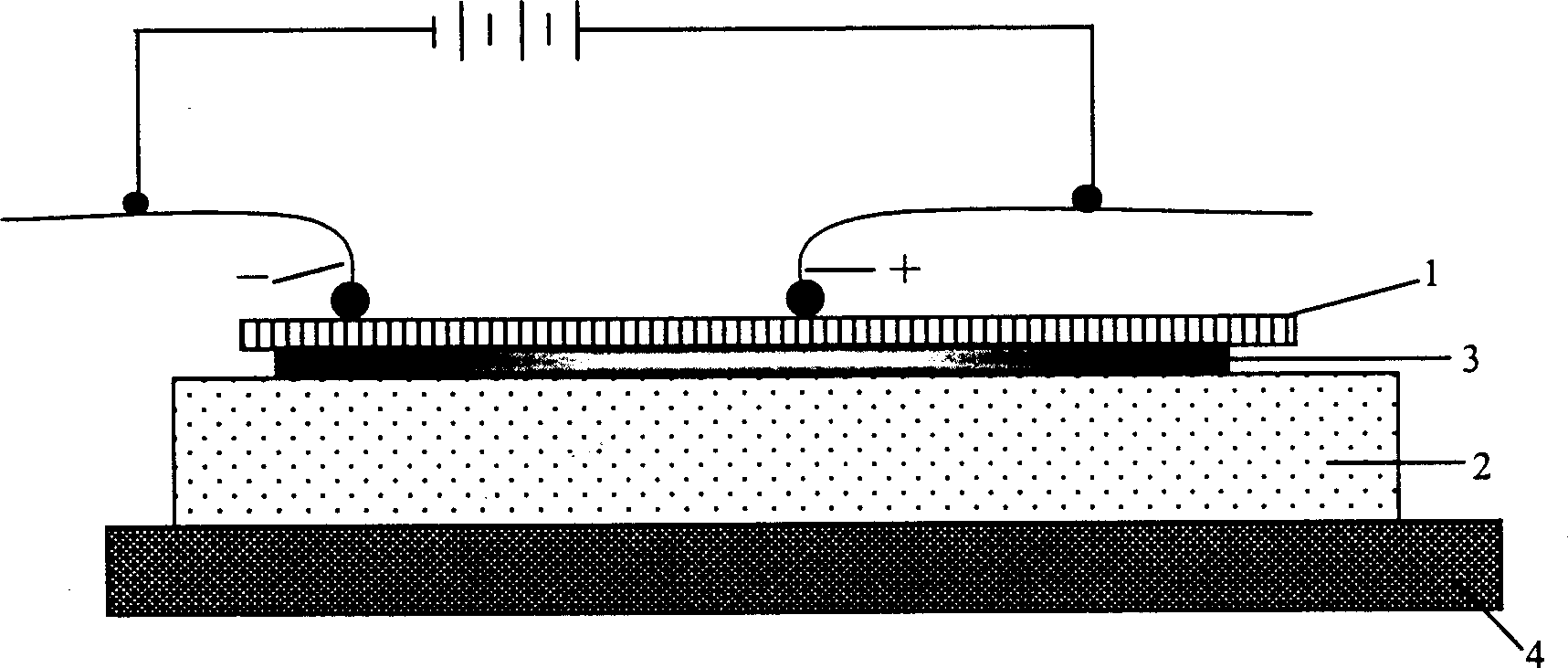

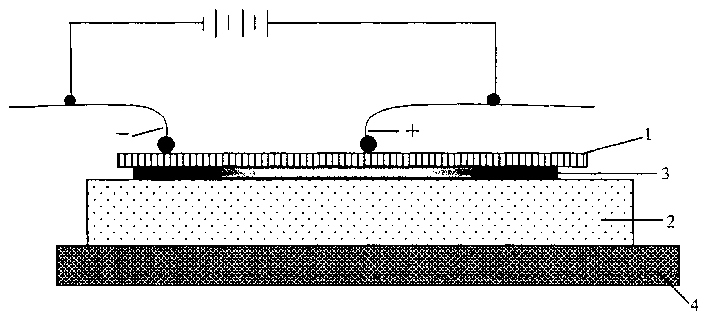

[0009] figure 1 Among them, 1 is the p-type layer, 2 is the n-type layer, 3 is the light-emitting layer, and 4 is the base. When testing, place positive and negative electrodes on the surface of the LED epitaxial wafer and add a high-voltage constant current source. Due to the breakdown of the reverse diode, the luminous condition of the measured point can be measured. After measuring a point, move the positive electrode, and the same method as above can continue to detect, and continuously move the positive electrode to measure the luminescence status of the entire LED epitaxial wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com