Delay coking process able to flexibly regulate recirculating ratio

A technology of delayed coking and cycle ratio, which is applied in the field of delayed coking technology, can solve the problems of coking and poor quality of coking wax oil, etc., and achieve the effects of increasing the total liquid recovery, reducing the severity, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

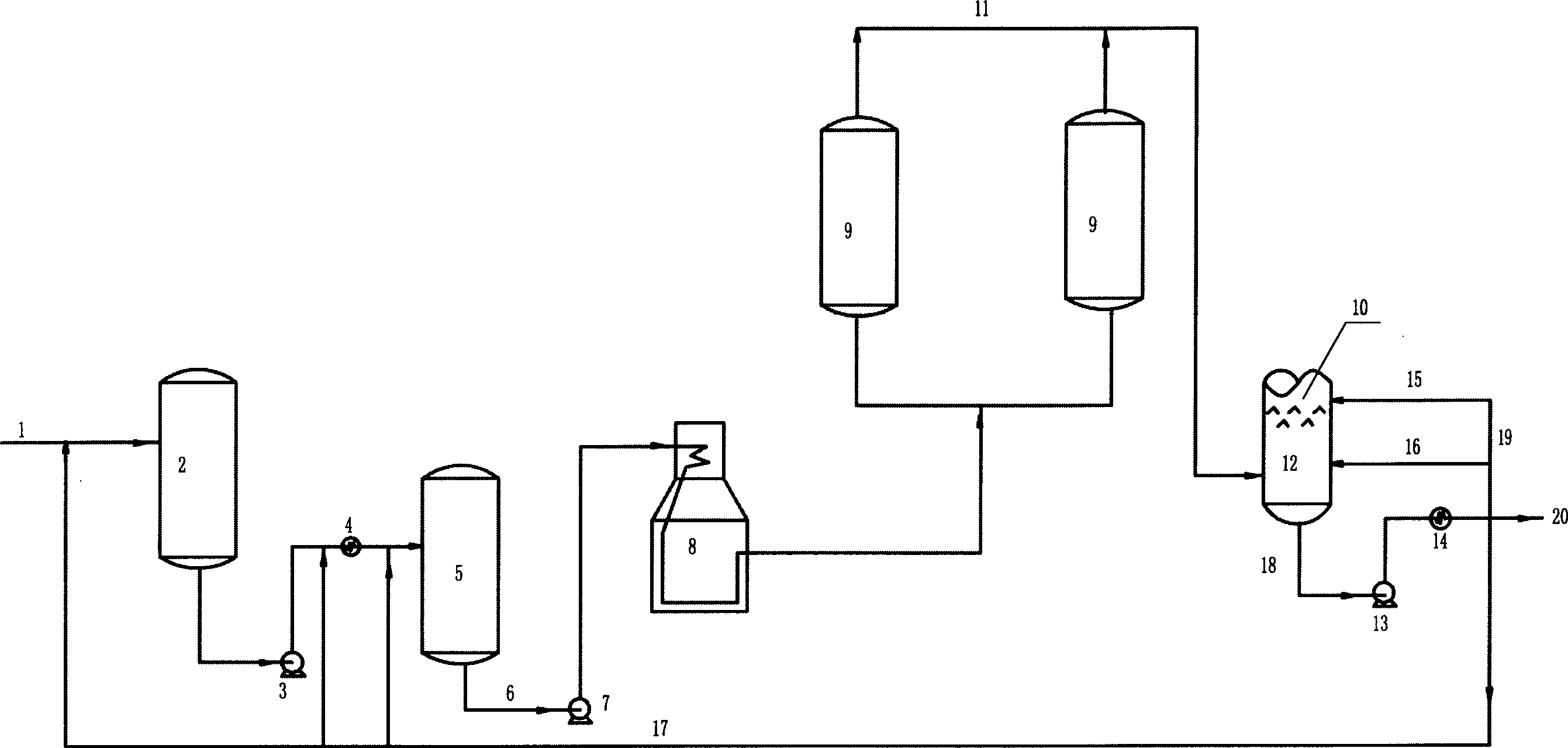

[0026] As shown in the figure: the coking raw material from the pipeline 1 enters the raw material buffer tank 2, after being boosted by the raw material pump 3, it enters the heat exchange system 4, and after exchanging heat to 200-350°C, it enters the coking heating furnace feed buffer tank 5. Coking heating furnace feed 6 is pumped out by radiation feed pump 7 to coking heating furnace 8 and heated to 495-505°C and enters coke tower 9, reaction oil gas 11 enters coking fractionation tower 12, and circulating oil 18 is transferred from coking fractionation tower 12 by circulating oil pump 13 The bottom is extracted, and the withdrawn circulating oil 18 is cooled by the cooler 14 and then divided into three routes: one is the reflux 19 back to the lower part of the coking fractionation tower 12, the other is the coking circulating oil 17 mixed with the coking raw material 1, and the other is the product 20 out of the device. In the figure, the reflux 19 is divided into two rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com