Sputtering target for high resistance transparent conductive membrane and mfg. method of high resistance transparent conductive membrane

A technology of transparent conductive film and manufacturing method, which is applied in the direction of cleaning method using liquid, sputtering coating, cleaning method and utensils, etc., which can solve the problem of large equipment investment, inability to use DC magnetron sputtering device, and inability to ensure keys Control panel strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare In with a purity >99.99% 2 o 3 Powder and SnO 2 Powder, and SiO with purity>99.9% 2 pink. According to SnO 2 10wt%, SiO 2 5wt%, In 2 o 3 This powder was prepared at a ratio of 85% by weight and a total amount of 1.5 Kg (Si corresponds to about 0.13 mol to 1 mol of In), and a molded body was obtained by filtration molding. Then, the sintered body was fired and sintered in an oxygen atmosphere at 1550° C. for 8 hours. This sintered body was processed to obtain a target having a relative density of 100% to the theoretical density. The volume resistivity of the target is 2.4×10 -4 Ωcm.

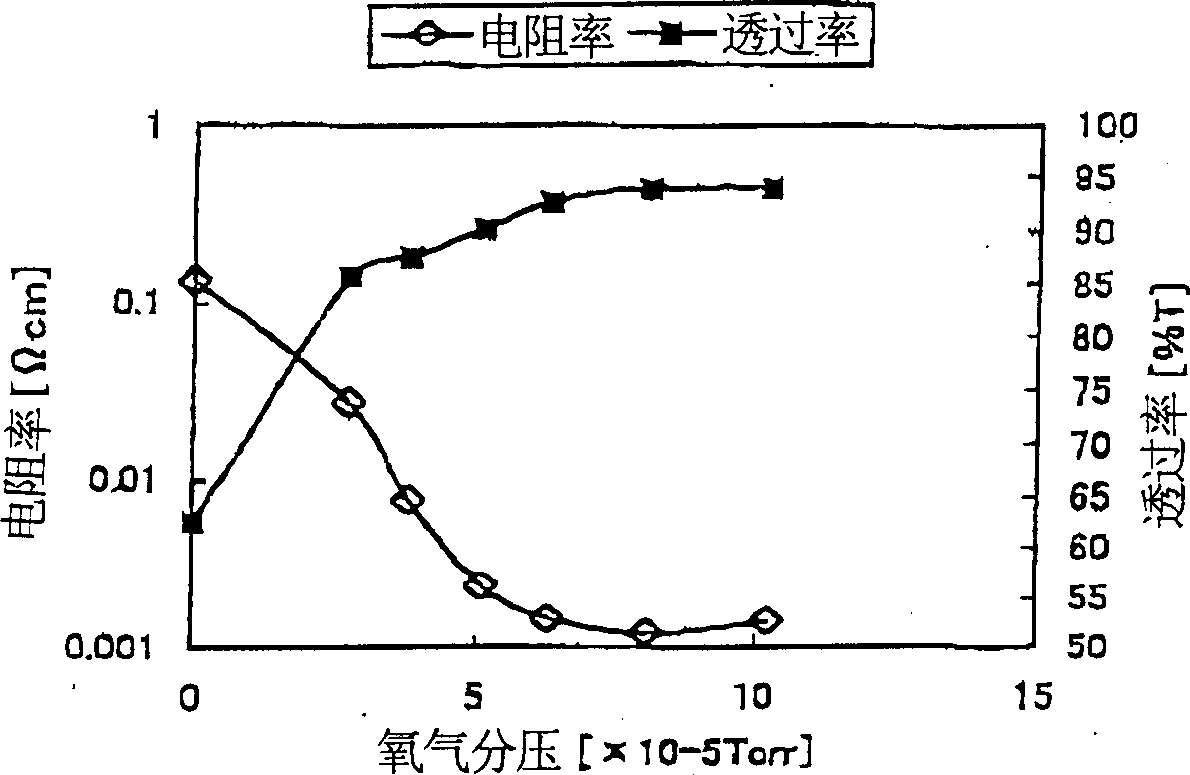

[0048] Using this target, a film was formed by DC magnetron sputtering under the following conditions to obtain a film with a thickness of 1200 Å.

[0049] Target size: φ=6in.τ=6mm

[0050] Sputtering method: DC magnetron sputtering

[0051] Exhaust device: rotary pump + cryopump

[0052] Reached vacuum degree: 4.0×10 -5 [Torr]

[0053] Ar pressure: 3.0×10 -3 [Torr]...

Embodiment 2

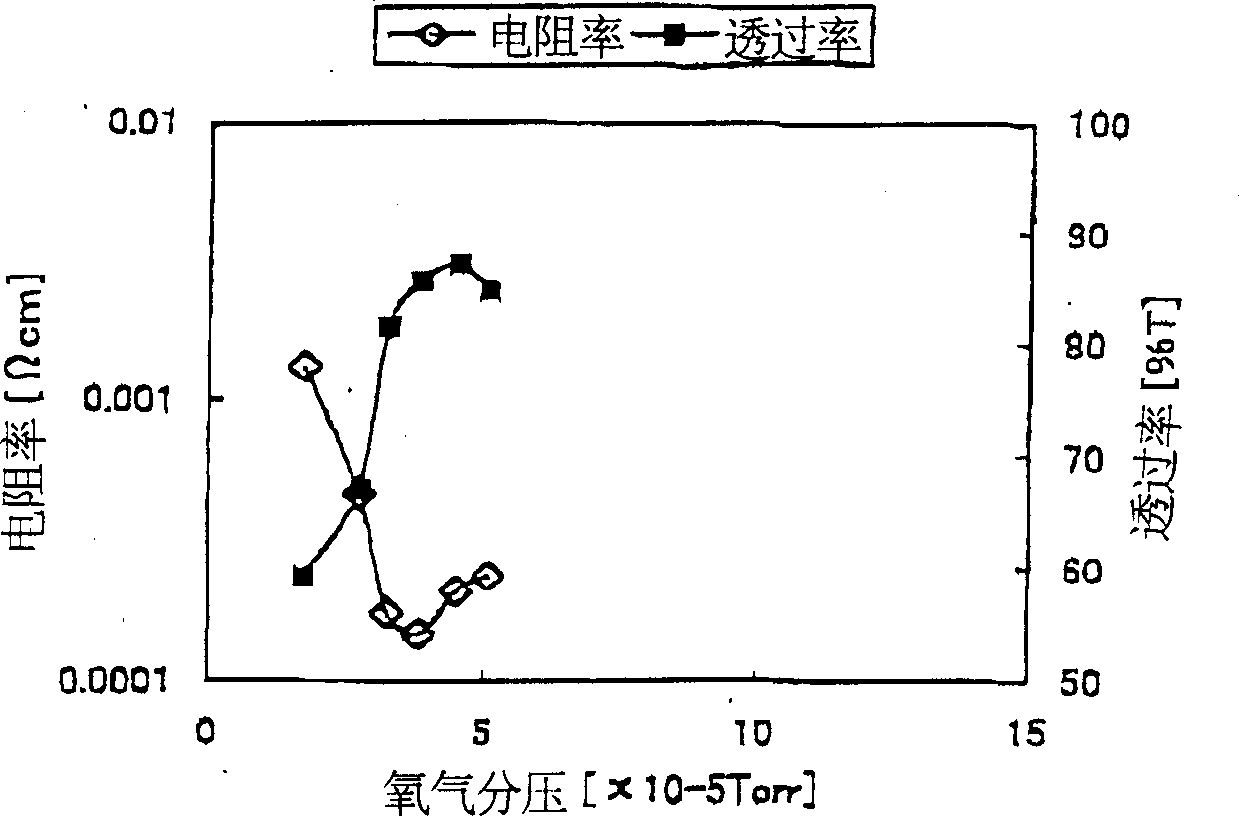

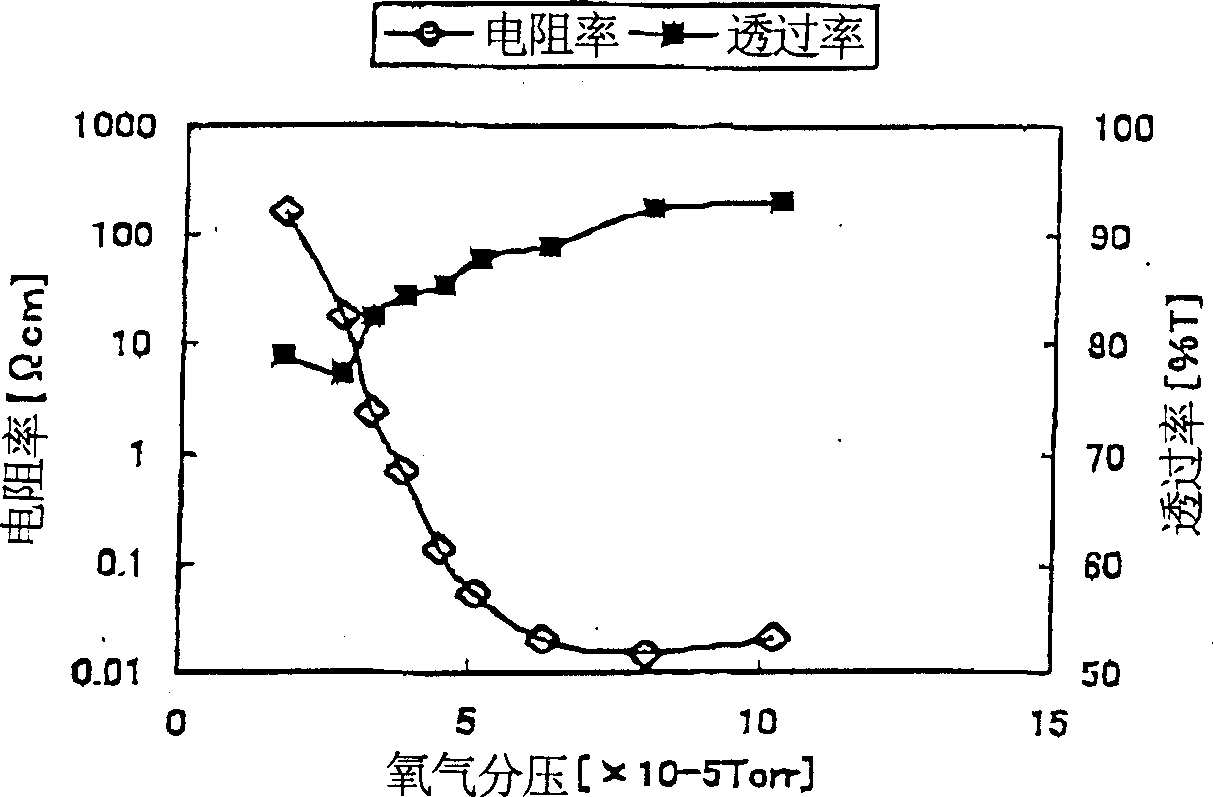

[0063] Prepare In with a purity >99.99% 2 o 3 Powder and SnO 2 Powder, and SiO with purity>99.9% 2 pink. According to SnO 2 10wt%, SiO 2 10wt%, In 2 o 3 This powder was prepared at a ratio of 80 wt % and a total amount of 1.5 Kg (Si corresponds to about 0.26 mol to 1 mol of In), and a molded body was obtained by filtration molding. Then, the sintered body was fired and sintered in an oxygen atmosphere at 1550° C. for 8 hours. This sintered body was processed to obtain a target having a relative density of 100% to the theoretical density. The volume resistivity of the target is 4.0×10 -4 Ωcm.

[0064] Using this target, a film was formed by DC magnetron sputtering under the same conditions as in Example 1 to obtain a film with a thickness of 1200 Å. By analyzing the resistivity and transmittance of the film, we get image 3 Such a relationship between the resistivity against the partial pressure of oxygen and the transmittance at a wavelength of 550 nm.

Embodiment 3

[0066] Prepare In with a purity >99.99% 2 o 3 Powder and SnO 2 Powder, and SiO with purity>99.9% 2 pink. According to SnO 2 10wt%, SiO 2 5wt%, In 2 o 3 This powder was prepared at a ratio of 85% by weight and a total amount of 1.5 Kg (Si corresponds to about 0.13 mol to 1 mol of In), and a molded body was obtained by filtration molding. Then, the fired body was fired and sintered in an oxygen atmosphere at 1450° C. for 8 hours. This sintered body was processed to obtain a target having a relative density of 100% to the theoretical density. The volume resistivity of the target is 3.0×10 -4 Ωcm.

[0067] Using this target, a film was formed by DC magnetron sputtering under the same conditions as in Example 1 to obtain a film with a thickness of 1200 Å. Analyzing the resistivity and transmittance of the film, it was shown that the same figure 1 Nearly equivalent oxygen partial pressure characteristics.

[0068] As can be seen from the above results, the volume resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com