Axially sliding connection brush appliance, its mfg. method and dynamo set with same brush

A technology of axial sliding and brush device, which is applied in the direction of electromechanical device, connection, and control of mechanical energy, etc. It can solve the problems of large size of brush damper components, failure of vibration damper installation, deterioration of contact pressure of brush elastic body, etc. , to achieve the effect of good sliding connection position, good contact stability and excellent vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

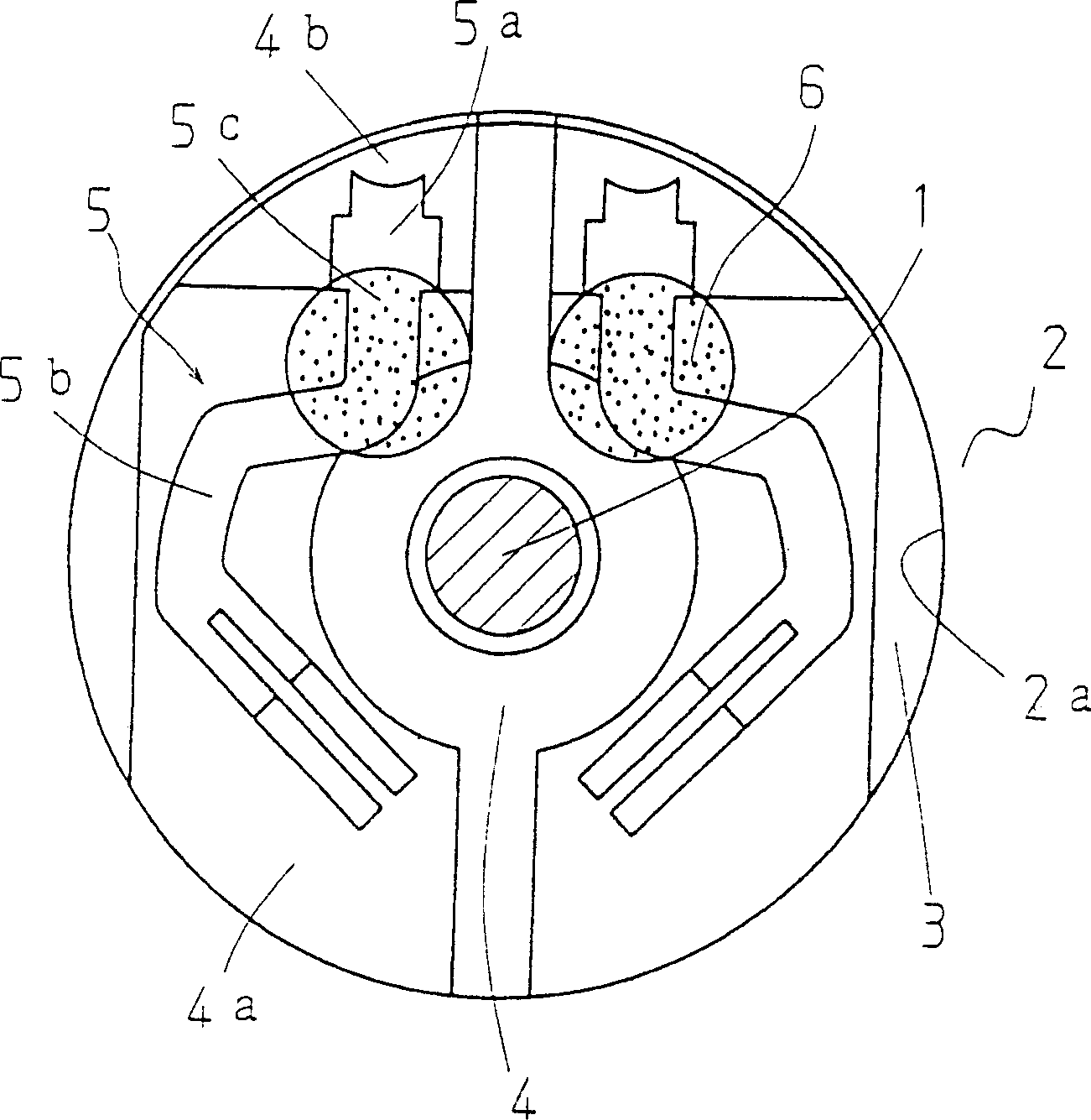

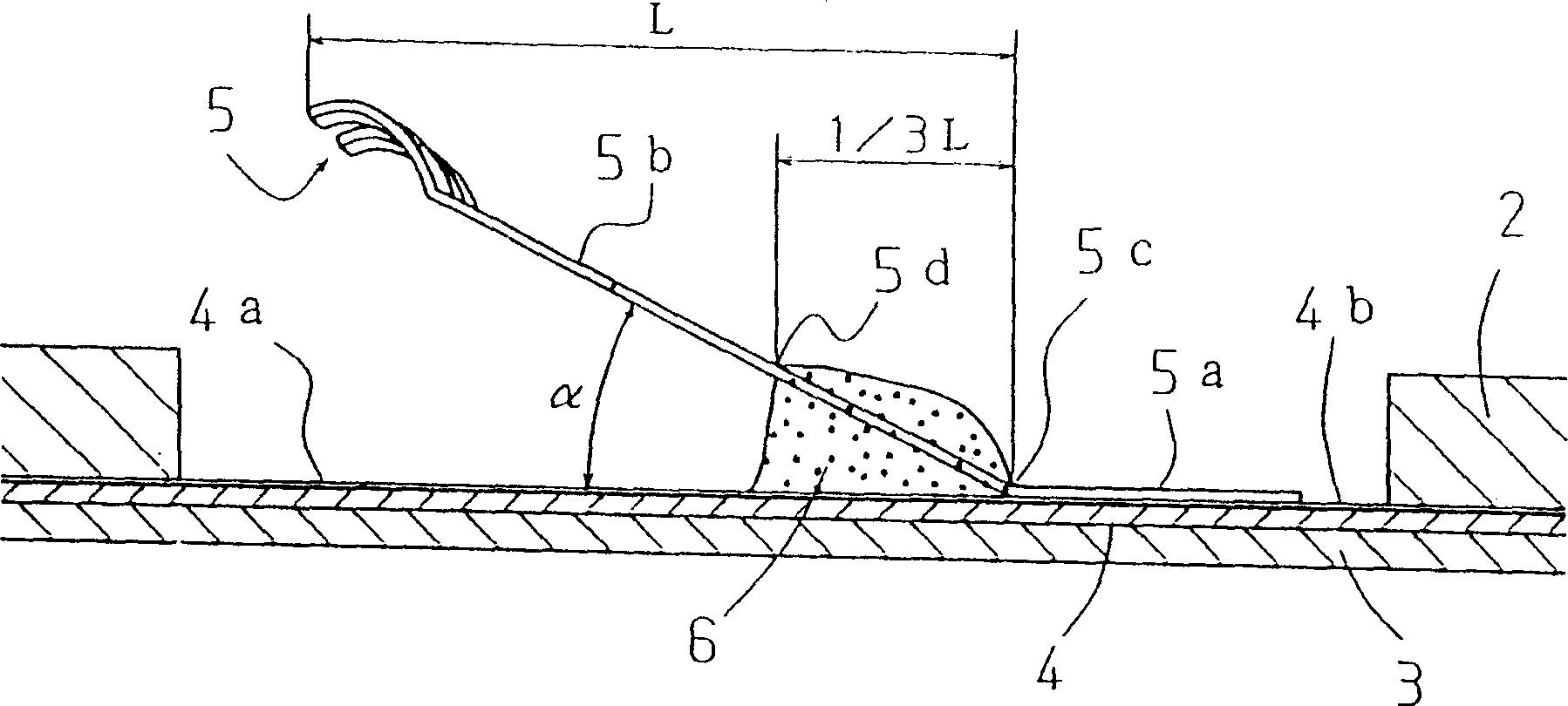

[0029] figure 1 It is a top view of main parts showing a brush device according to an embodiment of the present invention. figure 1 Among them, the above-mentioned rotating shaft 1 is inserted through the central hole 2a of the annular stator magnet 2 fastened coaxially with the rotating shaft 1 of the motor, and the stator magnet 2 and the bracket holding the stator magnet 2 In the gap between 3, brush base 4 is insertedly installed, and it is fastened on the side of bracket 3. On the exposed portion 4b of the stencil portion 4a of the brush base 4, the fastening portion 5a of the brush 5 is fastened by a method (soldering, welding, etc.) that does not affect conduction.

[0030] On the other hand, a pair of brush arms 5b are arranged symmetrically to the center of the rotating shaft 1, and the brush arms 5b have a planar curved shape in order to further increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com