Tee joint shape optimization design method

An optimized design and three-way technology, applied to mechanical equipment, branch pipelines, pipes, etc., can solve problems such as limited reinforcement effect and insufficient reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

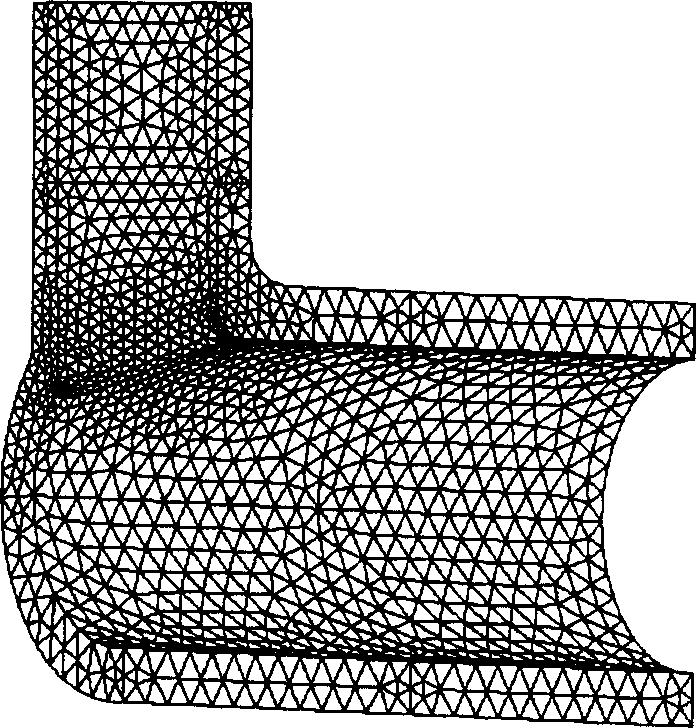

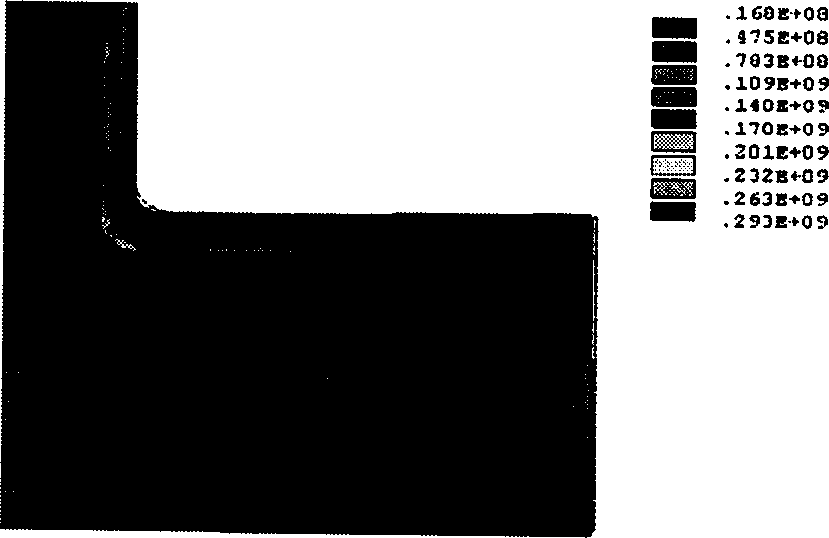

[0046] The following is the inventor's description of the technical solution adopted by the present invention by taking the optimization process of the hot extrusion tee used on the main steam pipeline of the 300MW steam turbine unit as an example. The maximum stress of the original design is 293MPa. After geometric correction, when the maximum correction amount is 10% of the outer diameter of the main pipe, the maximum stress is reduced by 52.2%, and the stress concentration factor is reduced from 3.74 to 1.79. Since the stress drop and the maximum correction amount are roughly linear in this range, the specific correction amount can be selected according to the expected maximum stress for the corresponding structure.

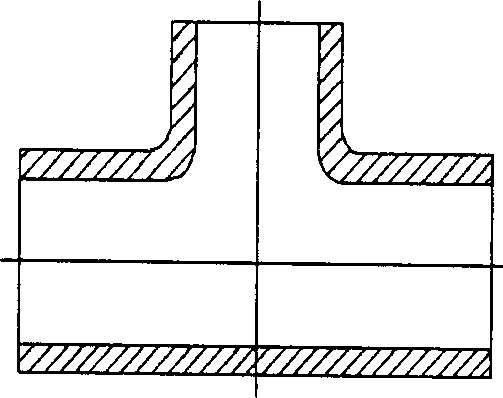

[0047] figure 1 It is a three-way structure diagram. Tee working pressure is 18.44MPa. Due to the relatively high pressure, the working deformation is relatively large, and the connecting pipe connected to it also has a large deformation near the end face. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com