Automatic scanning head optics regulating mechanism

An adjustment mechanism, optical automatic technology, applied in optics, optical components, instruments, etc., can solve the problems of high requirements for work proficiency, increased production costs, unsatisfactory and other problems, and achieves short adjustment time for optical mechanisms, improved position control accuracy, The effect of highlighting creative features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

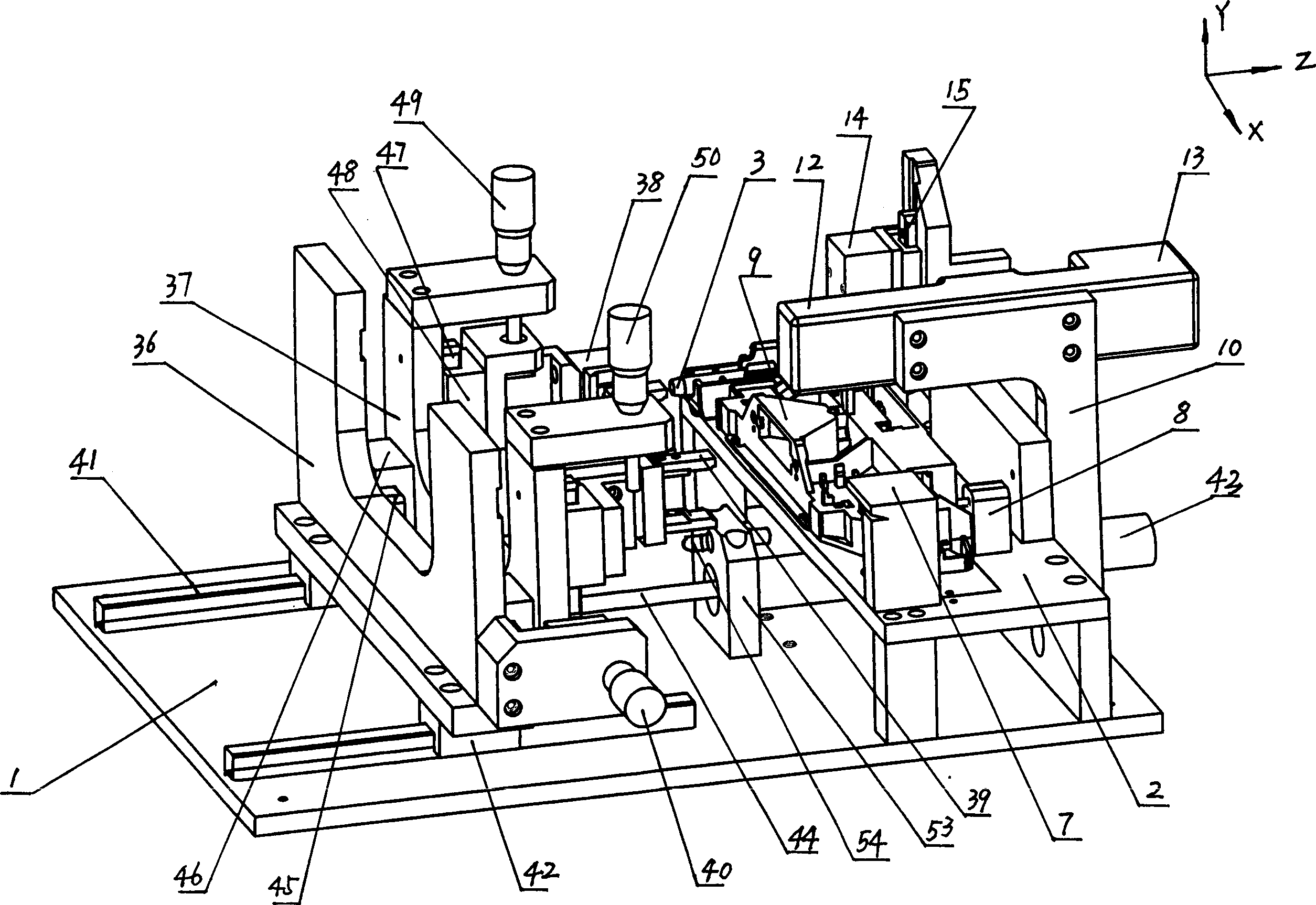

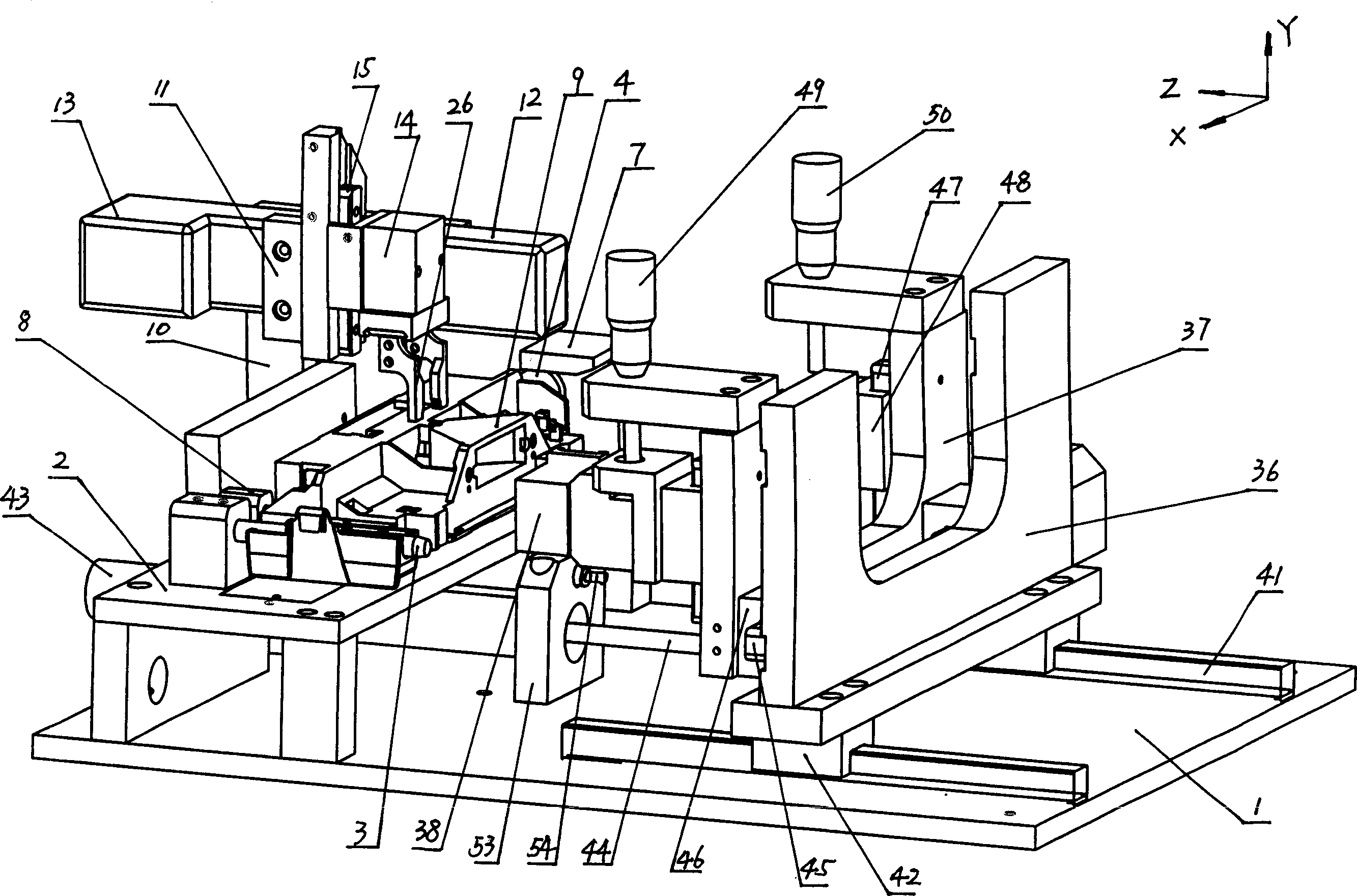

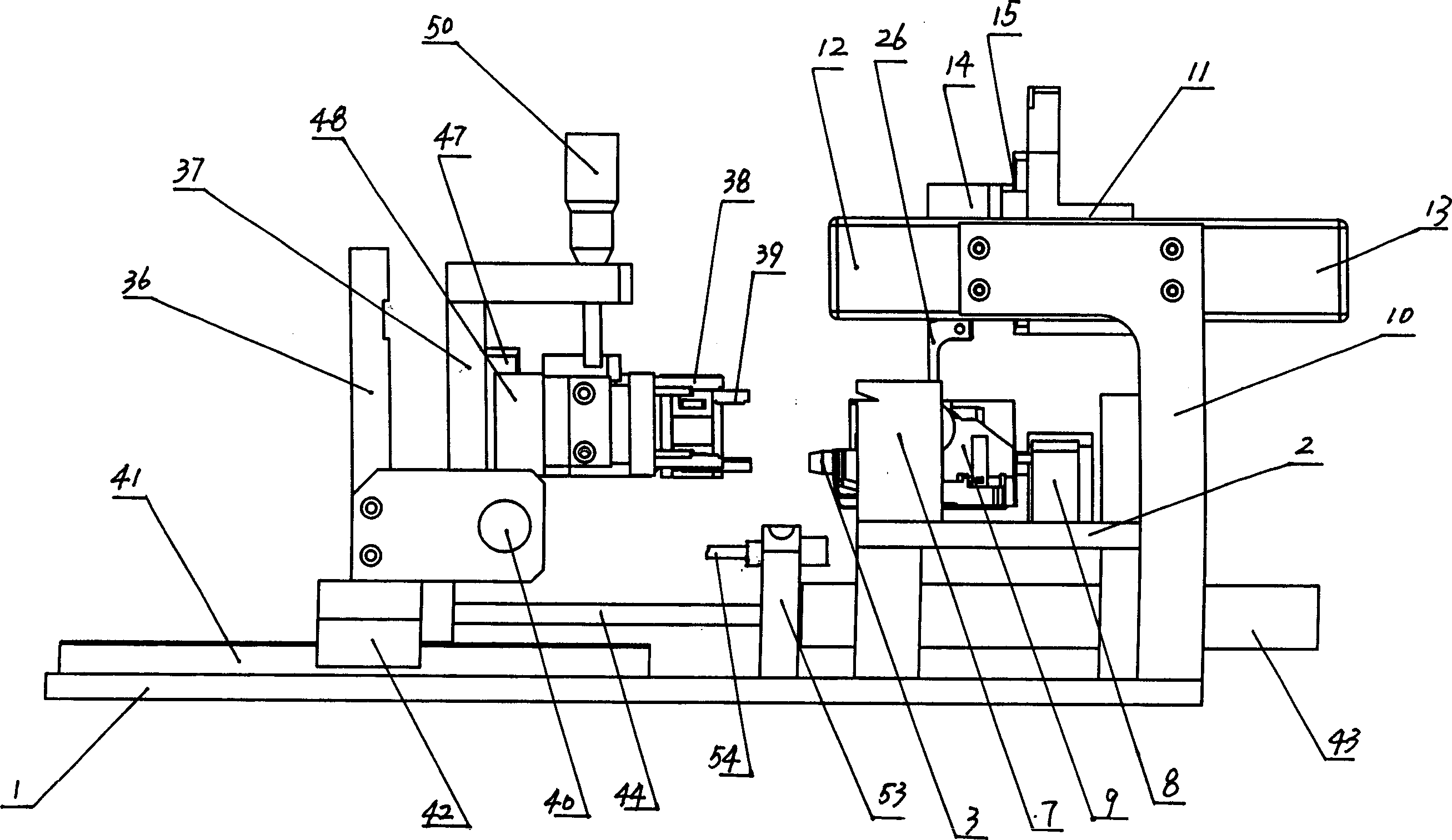

[0062] Example: see attached Figure 1 to Figure 5 As shown, a scanning head optical automatic adjustment mechanism is provided on a base 1 simultaneously with a scanning head positioning mechanism, a lens adjustment mechanism and a charge coupler adjustment mechanism. The following describes each of these three institutions:

[0063] 1. Scanning head positioning machine

[0064] See attached Figure 6 ~ Figure 8As shown, the mechanism is provided with a positioning frame 2, and the positioning frame 2 is provided with a three-dimensional space positioning reference and a pressing device. The three-dimensional space positioning reference is composed of a Z-direction positioning axis 3, a rotation positioning structure around the Z direction, and a moving positioning structure along the Z direction. One end of the Z-direction positioning shaft 3 is fixed on the positioning frame 2 through a fixed block, and the other end is suspended in the air so as to pass through the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com