Sealing structure, sealing method and sealing unit of organic LED

A light-emitting diode and sealing structure technology, which is applied in the direction of lighting devices, light sources, electric light sources, etc., can solve the problems of rising and complicated manufacturing costs of sealing operations, and achieve the effects of simple process, simple sealing structure, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

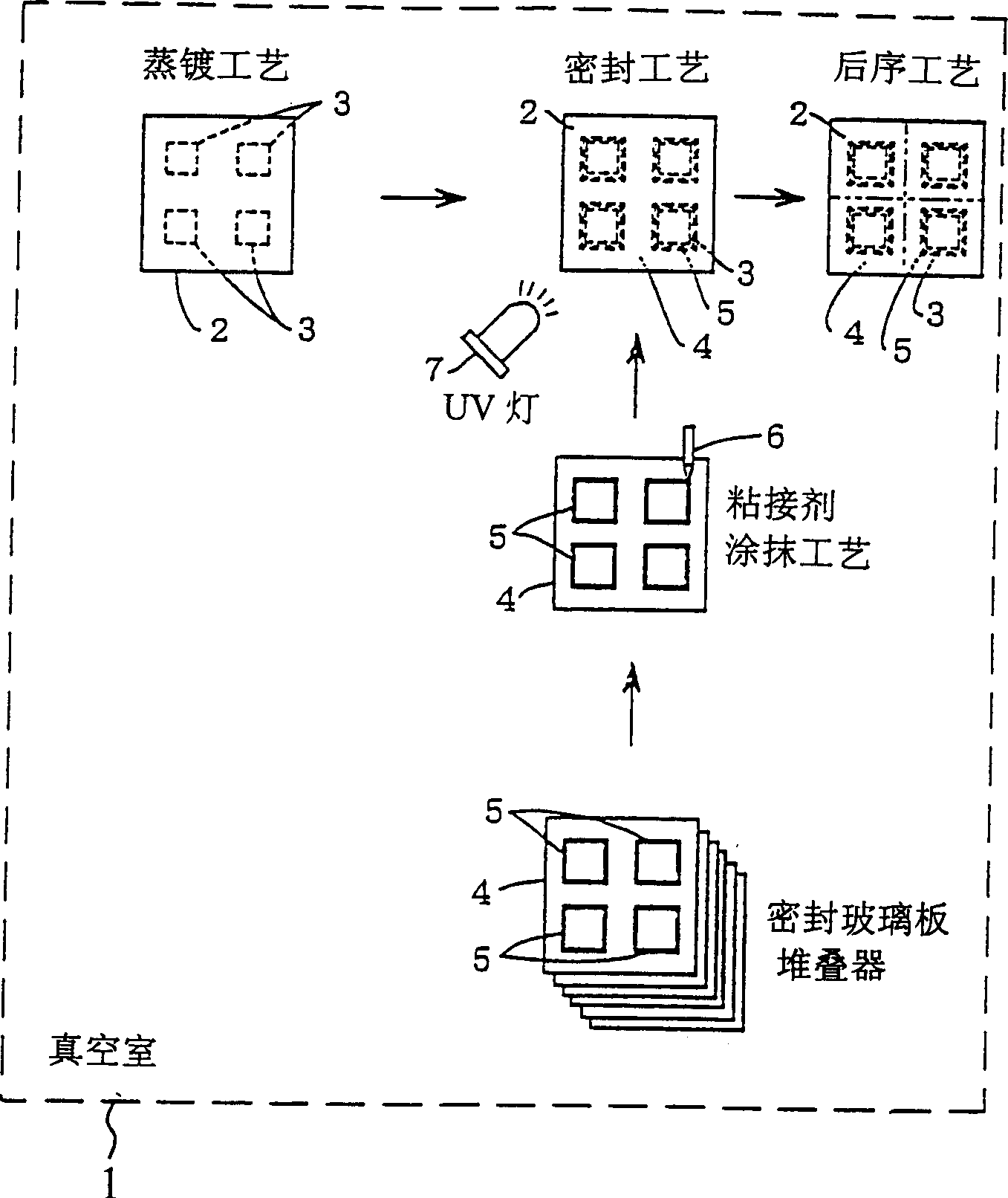

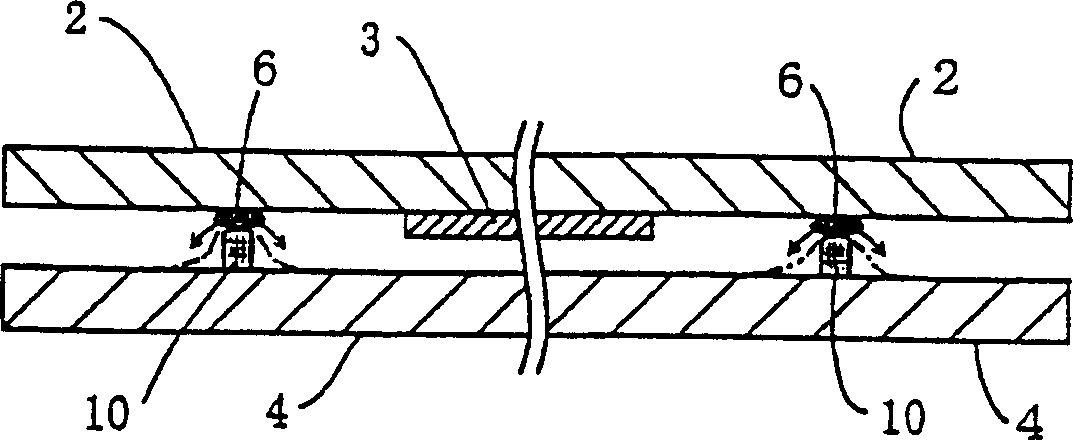

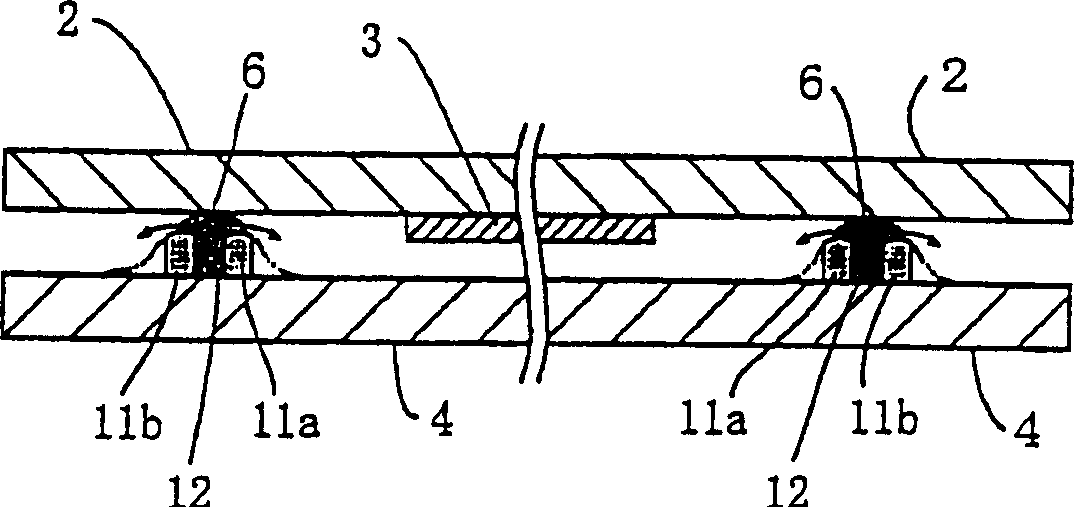

[0081] Various embodiments of the sealing structure, sealing method and sealing device of the organic light-emitting diode of the present invention will be described below with reference to the accompanying drawings. figure 1 is a flow chart illustrating the organic light-emitting diode sealing method of the present invention, showing an upside-down state in relation to the sealing device. exist figure 1 The process of the organic light emitting diode 3 is to form an organic light emitting layer and a metal electrode layer on the bottom of the glass substrate 2 in a vacuum chamber (not shown) for manufacturing the organic light emitting diode device. The sealing process is performed by moving the substrate 2 into the sealing vacuum chamber 1 which is a part of the vacuum chamber with the organic light emitting diode 3 facing downward. The sealing plate 4 for sealing the organic light emitting diode 3 is made of transparent glass, but as will be described later, other material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com