Socket joint type pipe head

A pipe joint and socket-type technology, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc. High assembly precision requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

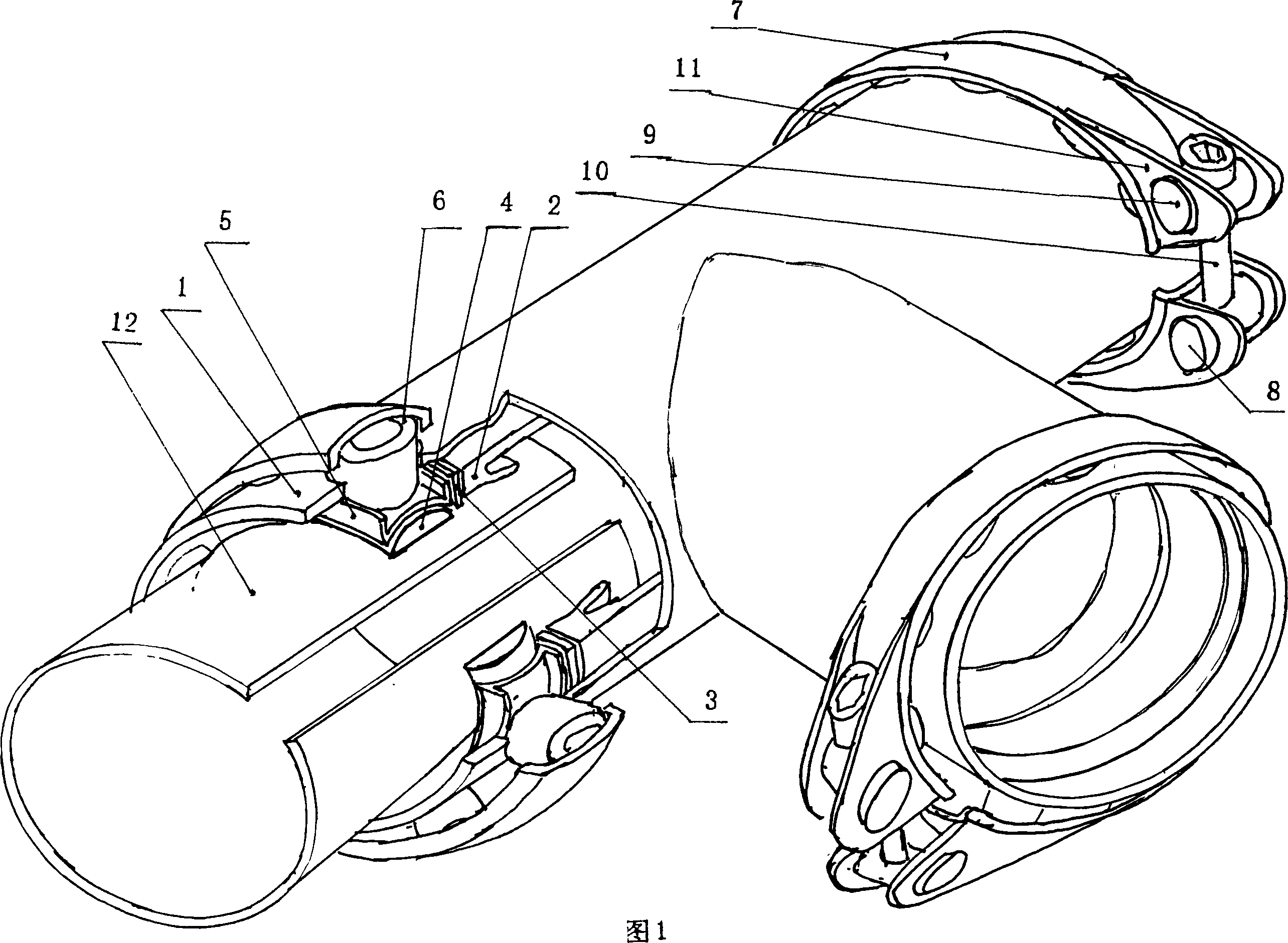

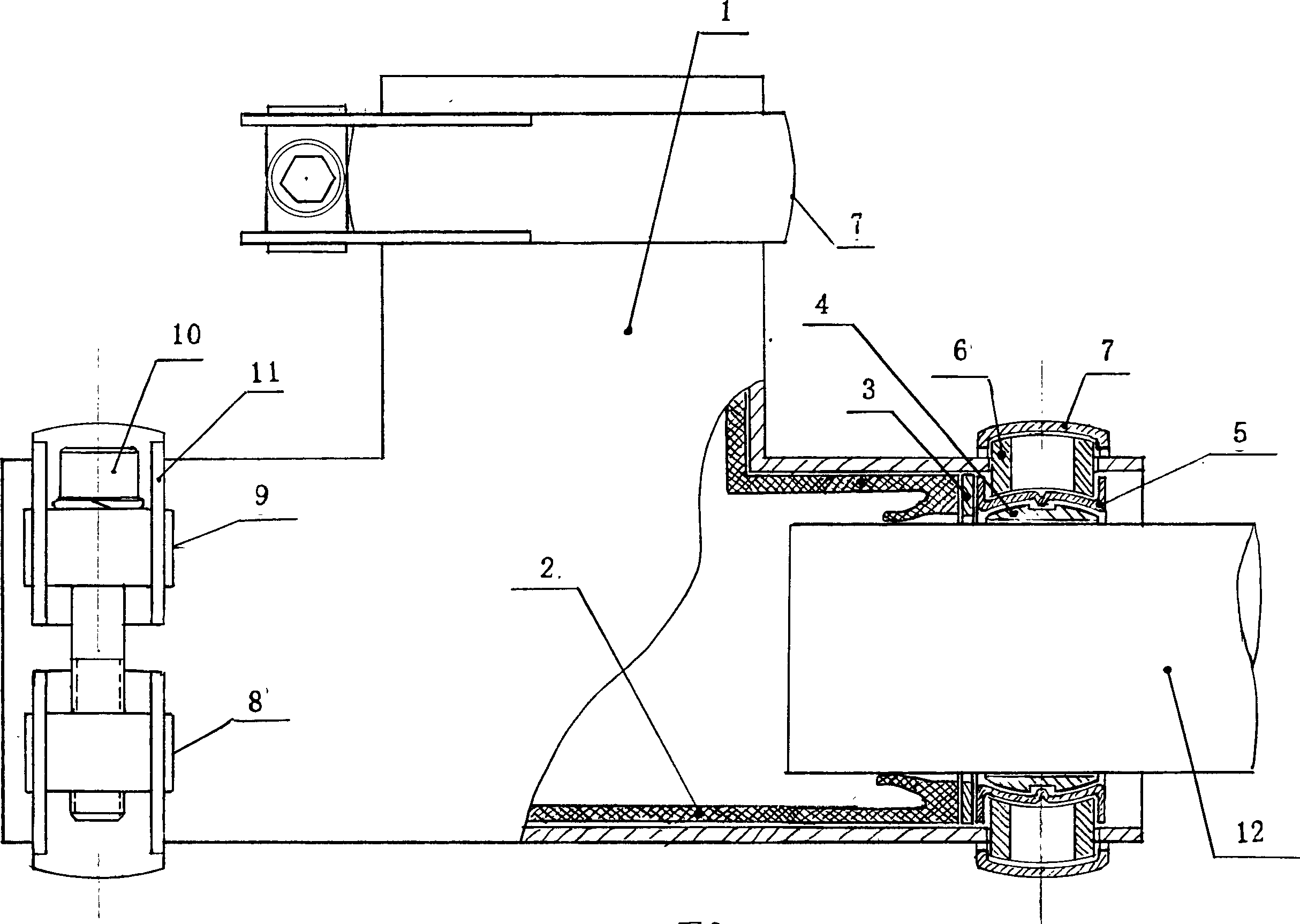

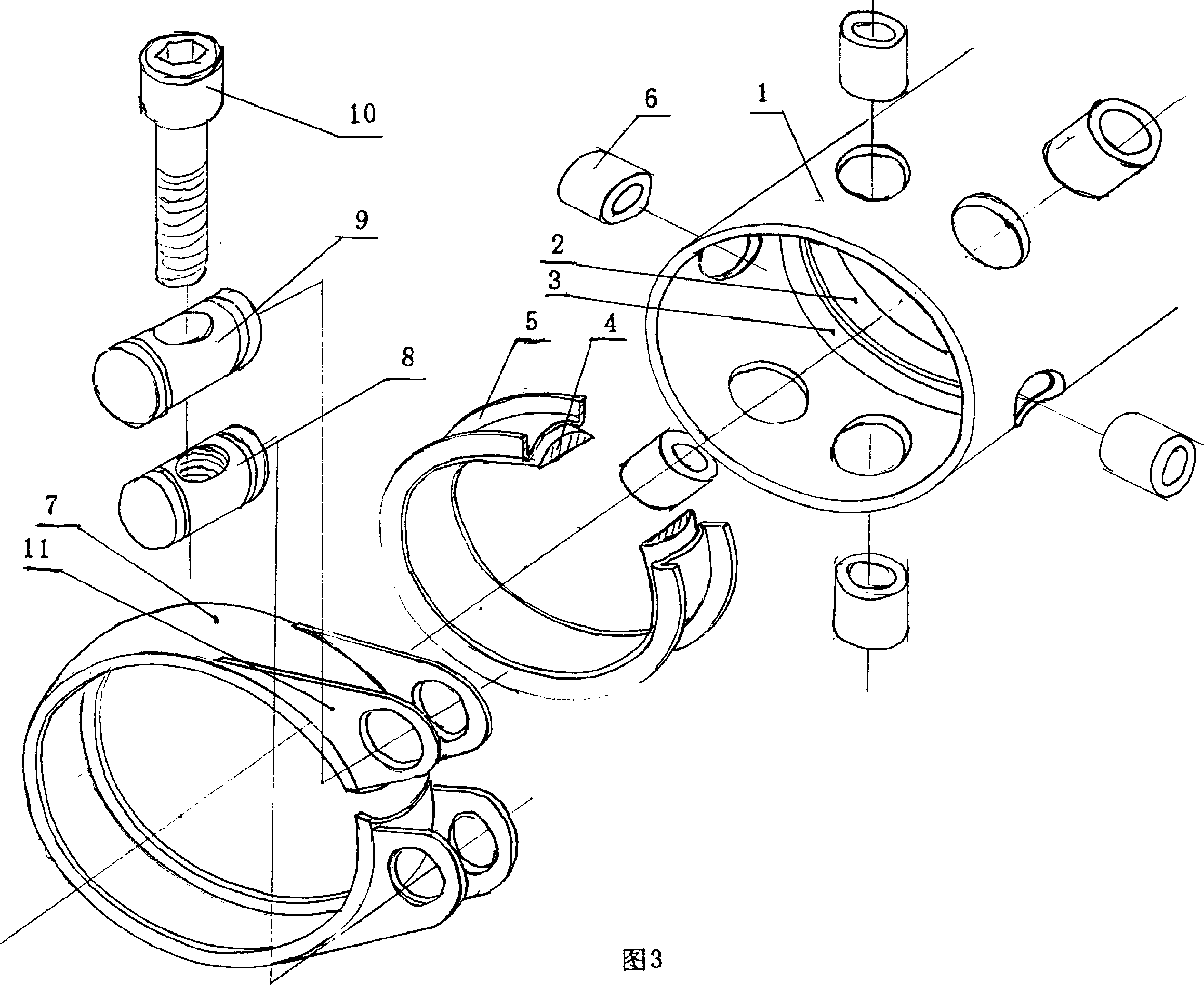

[0008] As shown in attached drawings 1 to 3, this joint is composed of body 1, rubber sealing sleeve 2, sealing sleeve retaining ring 3, inner locking ring 4, limit ring 5, hollow locking column 6, outer locking ring 7. The locking pin with screw hole 8, the locking pin with through hole 9, the locking bolt 10, the outer locking ring lug 11, etc., wherein at each port of the body 1, there are more than three through holes, and the body It can be made into one-way, two-way, two-way, four-way, multi-way or pipe plug, and can be made into variable diameter interface; the rubber sealing sleeve 2 is put into the body 1, and then put into the sealing sleeve retaining ring 3; inner locking The ring 4 and the limit ring 5 are put into the body 1 together, so that the limit ring 5 is close to the sealing sleeve retaining ring 3, and an opening and a positioning groove are provided on the inner locking ring 4, and the center of the limit ring 5 is set There is a positioning flange; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com