On-line gas survey system for drilling mud

A drilling mud and mud technology, applied in the field of drilling mud online gas measurement system, can solve the problems of time lag, low minimum detection value, single content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

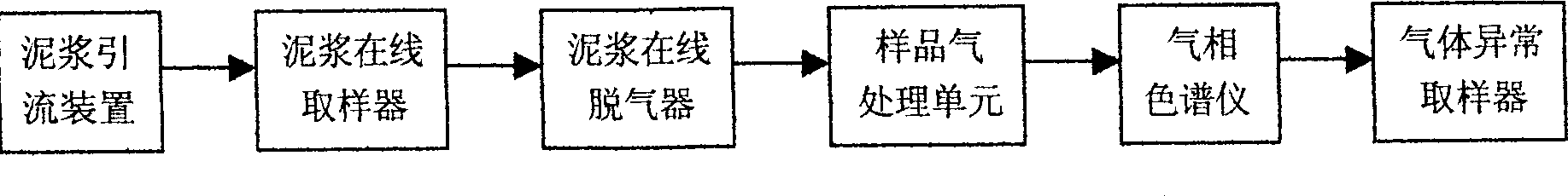

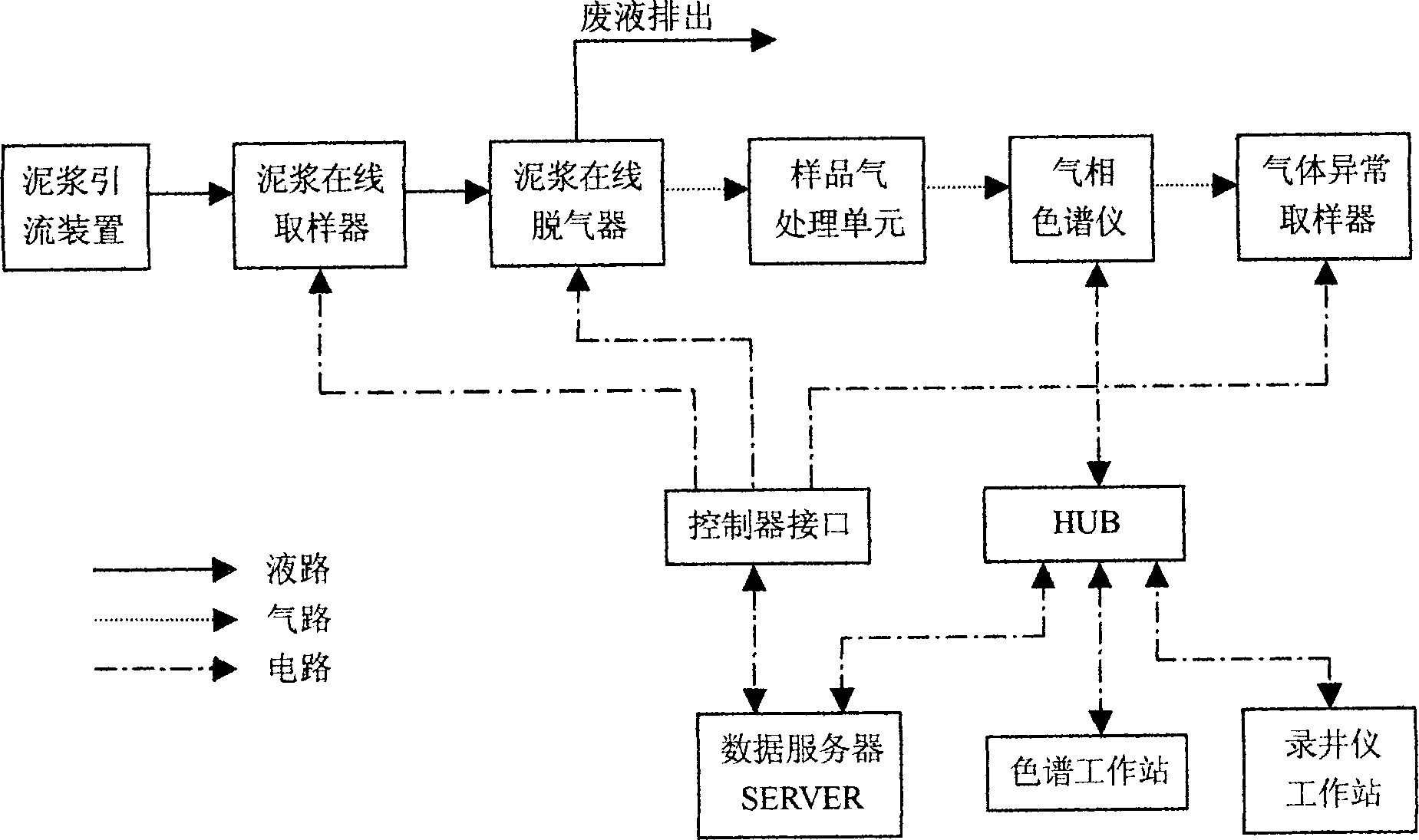

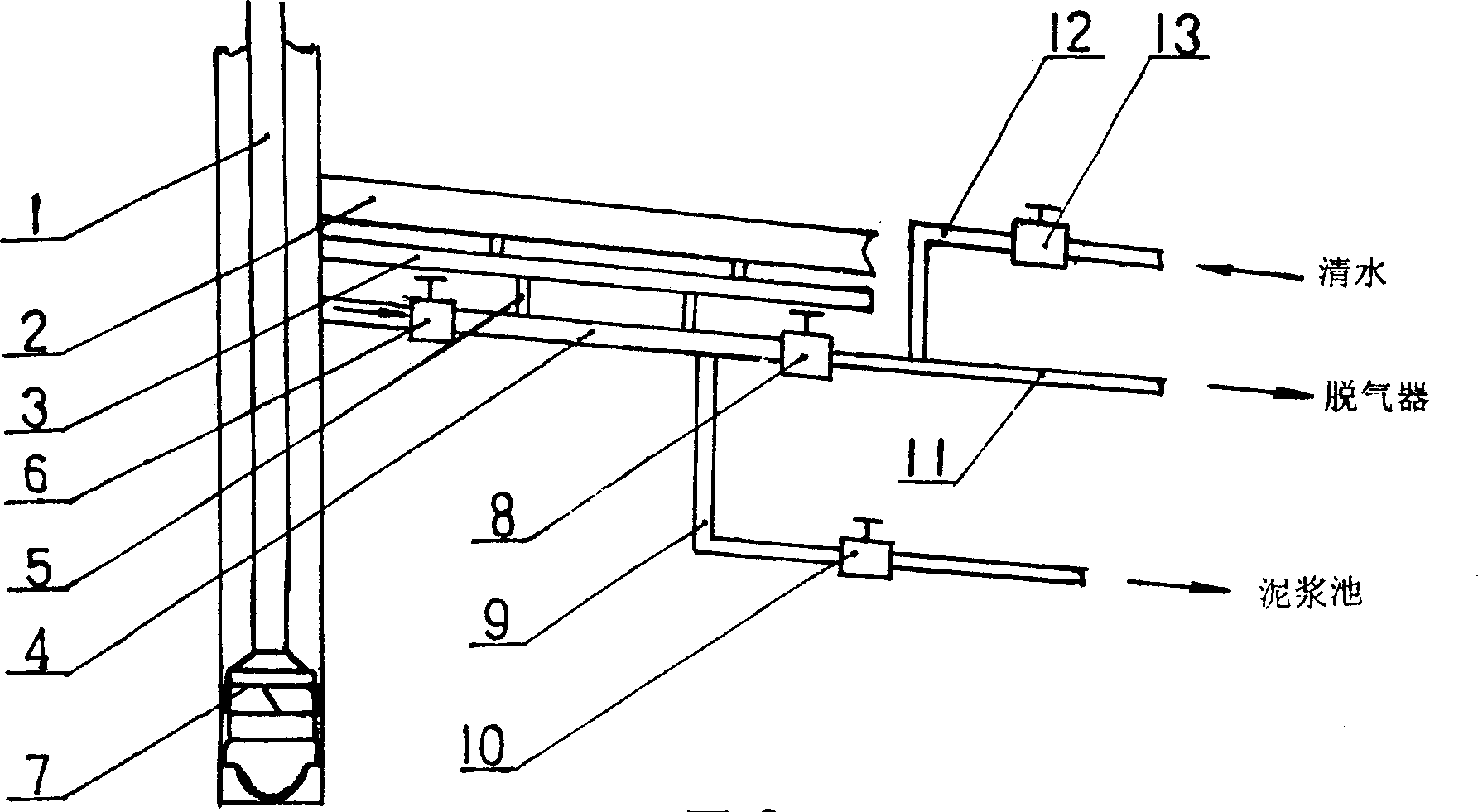

[0025] Such as figure 1 , 2 As shown, the system consists of a mud drainage device, a mud online sampler, a mud online degasser, a sample gas processing unit, a chromatograph and an abnormal gas sampler. Its automatic control part is composed of data server (SERVER), controller interface, chromatography workstation, logging instrument workstation and HUB. The technical characteristics of each of the above components are shown in Figure 3-9 shown.

[0026] The process flow and automatic control process of the system are:

[0027] Such as figure 1 , 2 As shown, the mud to be tested passes through the drainage device and is sent to the online mud sampler under the condition of completely isolating the air; the online mud sampler realizes the automatic sampling of abnormal conditions and the mud at the set well depth; then the mud sample is sent to the degasser The degassed mud returns to the vibrating screen and returns to the mud pool; the degassed sample gas passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com