Establishing method of dynamic model of liquid phase catalytic paraxylene oxidizing reaction

A technology of reaction kinetics and catalytic oxidation, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problem that the kinetic model is difficult to accurately describe the operation of industrial reactors, cannot be described, and the function deviation is large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

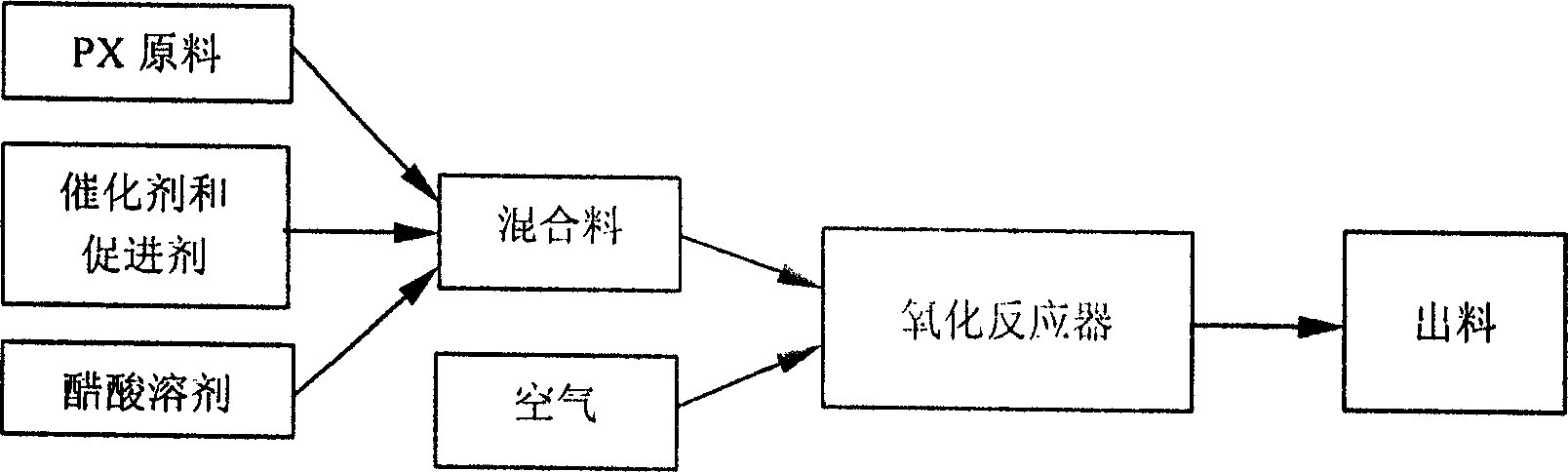

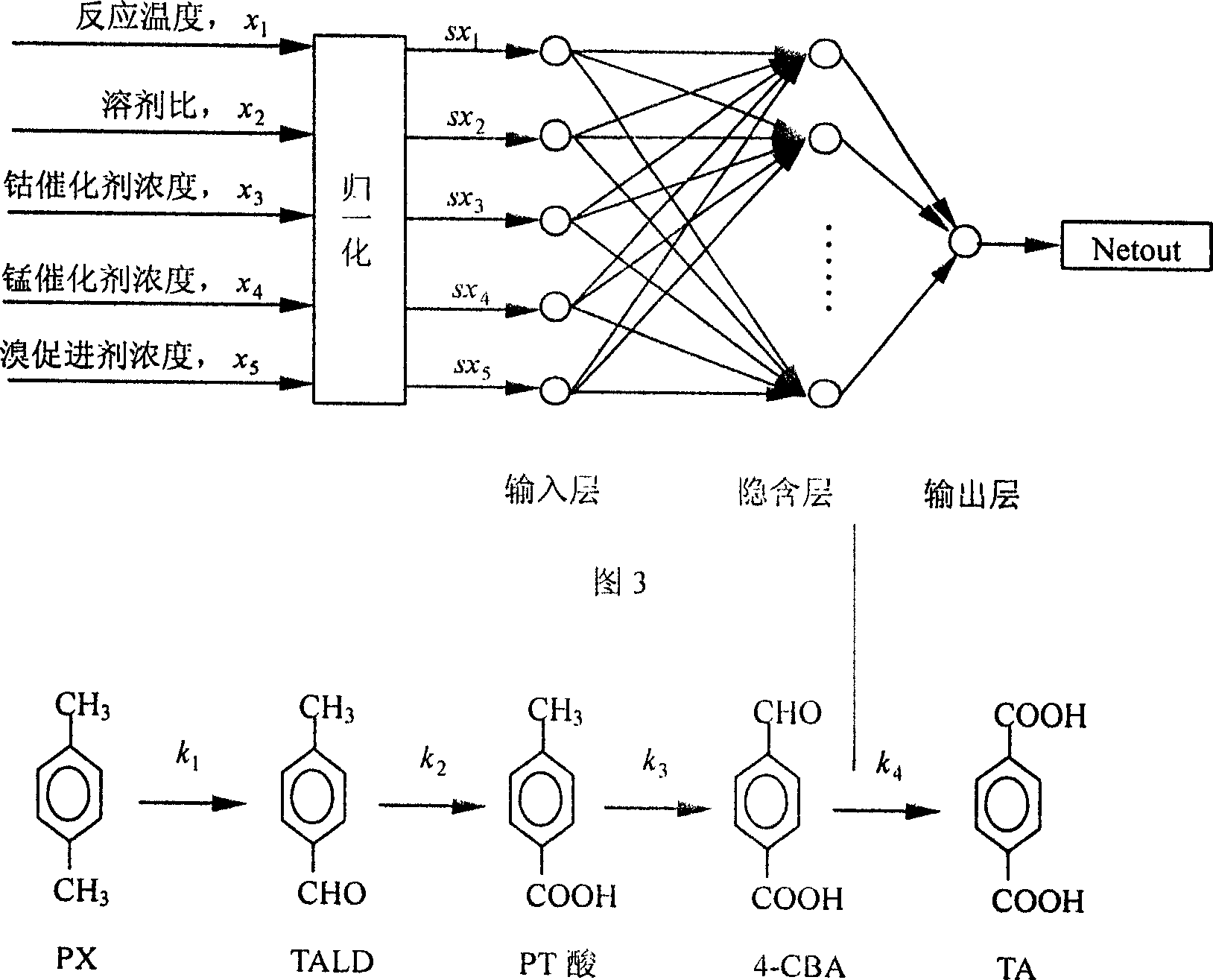

[0032] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

[0033] Collection of semi-continuous gas-liquid reactors in the laboratory at different reaction temperatures (x 1 , ℃), solvent ratio (x 2 , mol / Kg), cobalt catalyst concentration (x 3 , ppmw), manganese catalyst concentration (x 4 , ppmw), and bromine accelerator concentration (x 5 , ppmw), corresponding to the rate constant k of each step of the series of reactions 1 , i=1,2,3,4. Using formula (3), the above variables are normalized: x 1 The range of variation [181, 210], x 2 The range of variation [0.4, 4], x 3 The range of variation [0.01, 0.07], x 4 The range of variation [0.01, 0.07], x 5 The variation range of [0.01, 0.100], a total of 28 sets of data were collected, and each set of data contained [x 1 , x 2 , x 3 , x 4 , x 5 , k 1 , k 2 , k 3 , k 4 ].

[0034] pair rate constant k 1 The neural network model, each set of data co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com