Lithium niobate modulator and its making process

A manufacturing method and technology of lithium niobate, applied in instruments, electromagnetic wave transmission systems, optics, etc., can solve problems such as large insertion loss, high half-wave voltage, and low extinction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

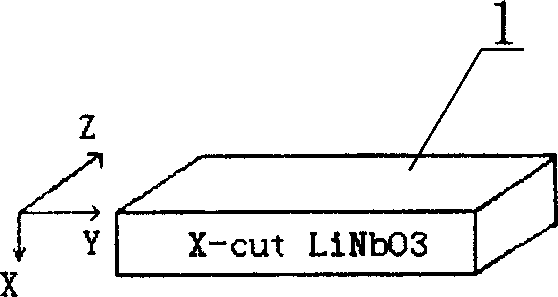

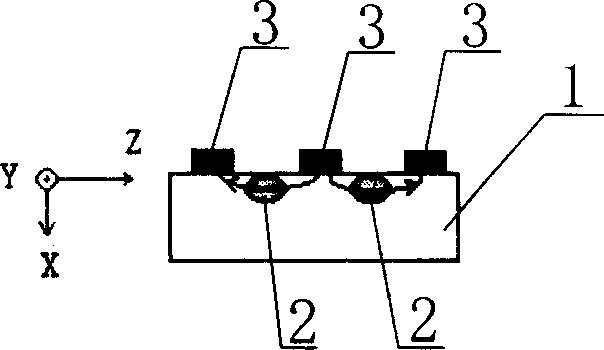

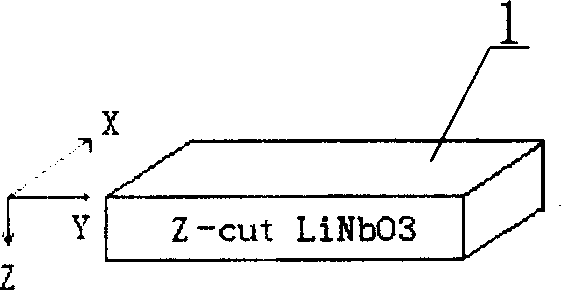

[0034] Such as Figure 1 to Figure 14 As shown, the lithium niobate modulator of the present invention includes:

[0035] The substrate 1 is prepared from a lithium niobate crystal with a suitable crystal tangential direction and electric field utilization direction; the electro-optical coefficients of the lithium niobate crystal in each direction are not the same. In order to obtain the maximum modulation efficiency in this embodiment, the modulation electrode is designed When using the maximum electro-optic coefficient γ of lithium niobate crystal 33 , that is, the electric field direction is parallel to the Z-axis direction of the crystal. When making lithium niobate optical waveguides, you can choose X-cut crystals or Z-cut crystals. The difference between the two is that the insertion loss of optical waveguides based on X-cut crystals is relatively small, while that based on Z-cut crystals The waveguide light effect is better than the former. gamma 33 The utilization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com