Double axial weft-knitted fabric, its knitting method and warp and weft feeding device of special flat-bed machine

A knitted fabric and biaxial technology is applied in the field of novel biaxial weft knitted fabric and its weaving method and special flat knitting warp and weft yarn feeding device, which can solve the problem of poor mechanical properties and the function of interweaving warp and weft yarns. , warp and weft layering, etc., to achieve the effect of improving impact resistance and flexible weaving methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

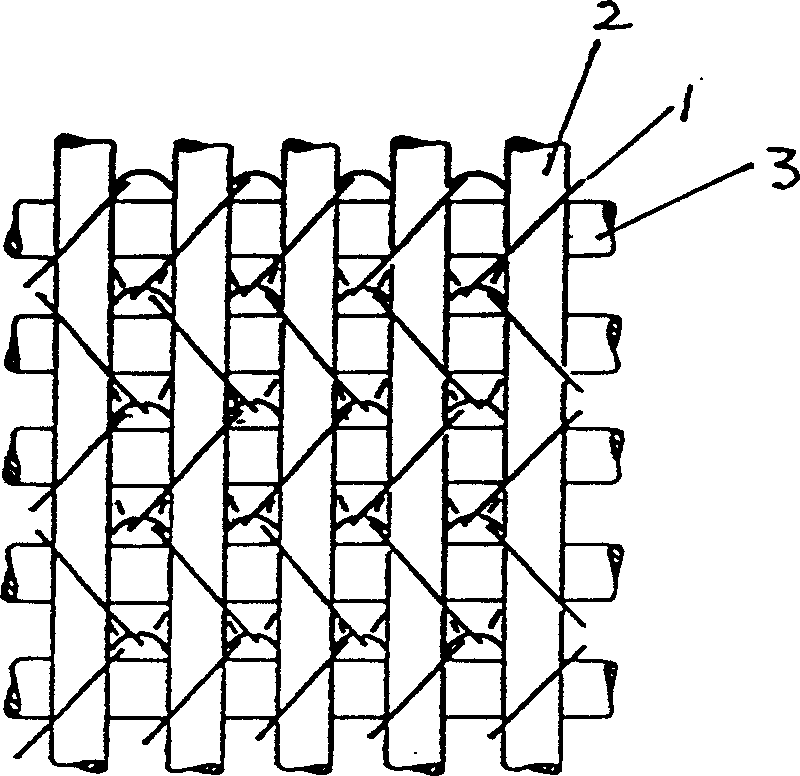

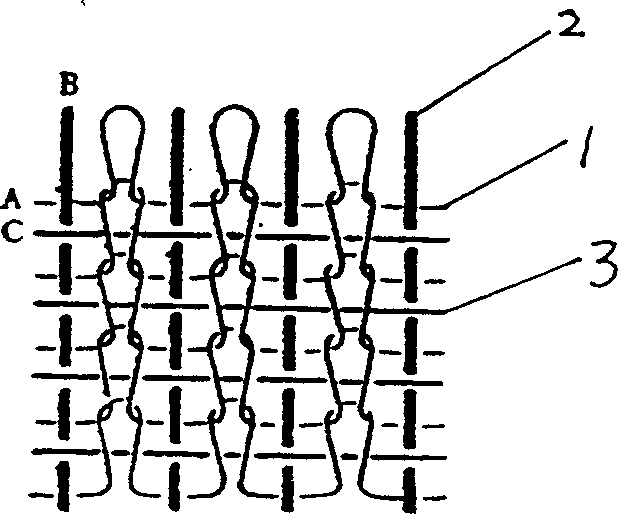

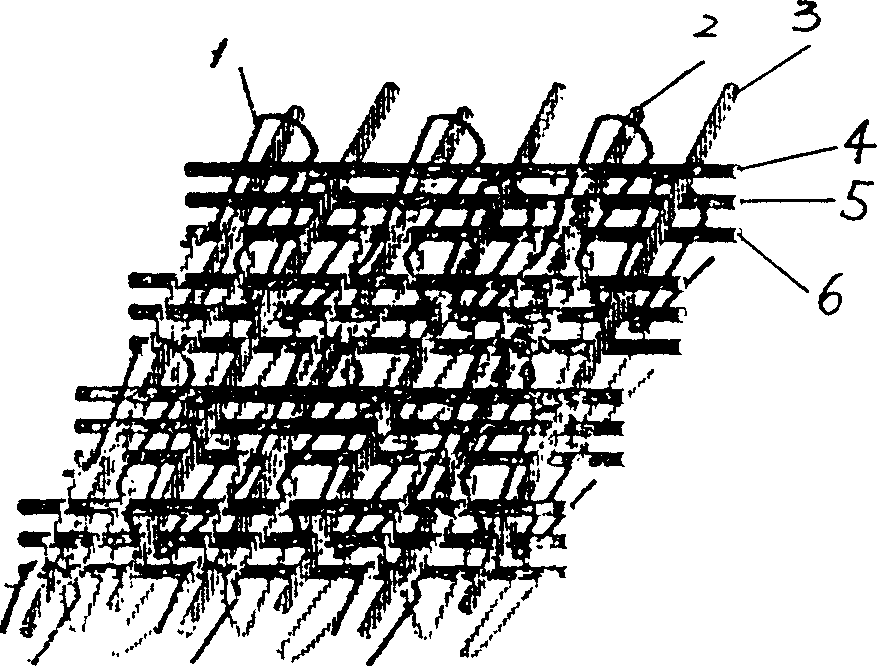

[0035] refer to Figure 4 , Figure 5 with Image 6 , a novel biaxial weft knitted fabric structure of the present invention ( Figure 4 ), which consists of weft flat stitch 1, warp 2 and weft 3. The weft yarn 3 is located on the reverse side of the weft flat stitch ground weave 1 and interweaves with the warp yarn 2. The warp yarn 2 alternately appears on the front side 4 and the back side 5 of the sinker arc of the weft flat stitch every two courses, and is connected with the ground weave 1. This is a fabric structure composed of knitted fabrics and woven fabrics.

[0036] The present invention adopts special biaxial flat knitting warp and weft yarn feeding device ( Figure 5 ) to weave the above-mentioned novel biaxial knitted fabric, the weaving process is as follows Image 6 Shown:

[0037] 1. Initial position: eg Image 6 Shown in (1), the knitting needle 2 has just completed the knitting of the previous knitting process and is at the lowest position. This momen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com