Method for producing natural stone brick plate

A natural and stone technology, applied in the field of manufacturing natural stone bricks, to achieve the effects of improved durability, greater durability and reduced danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

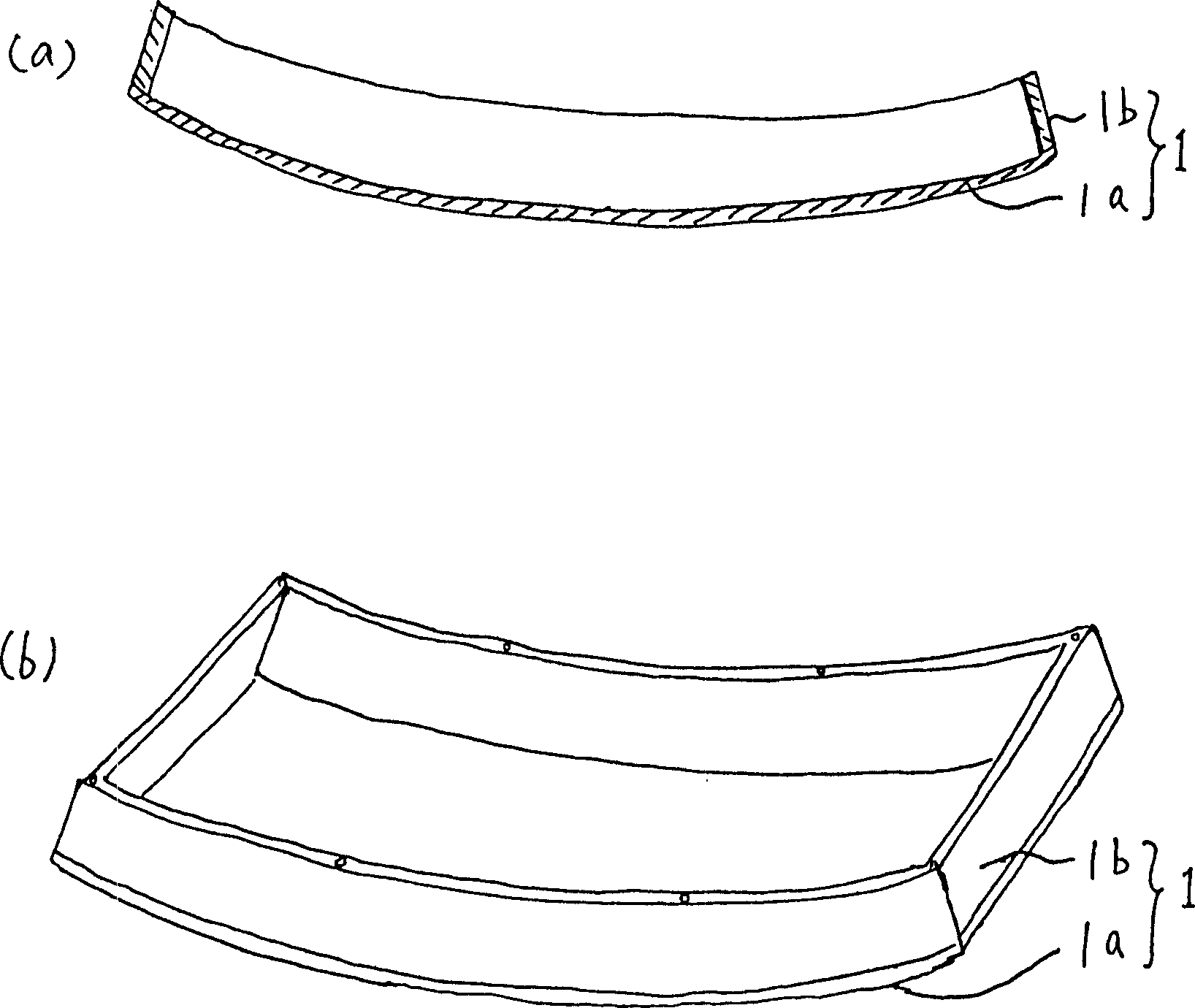

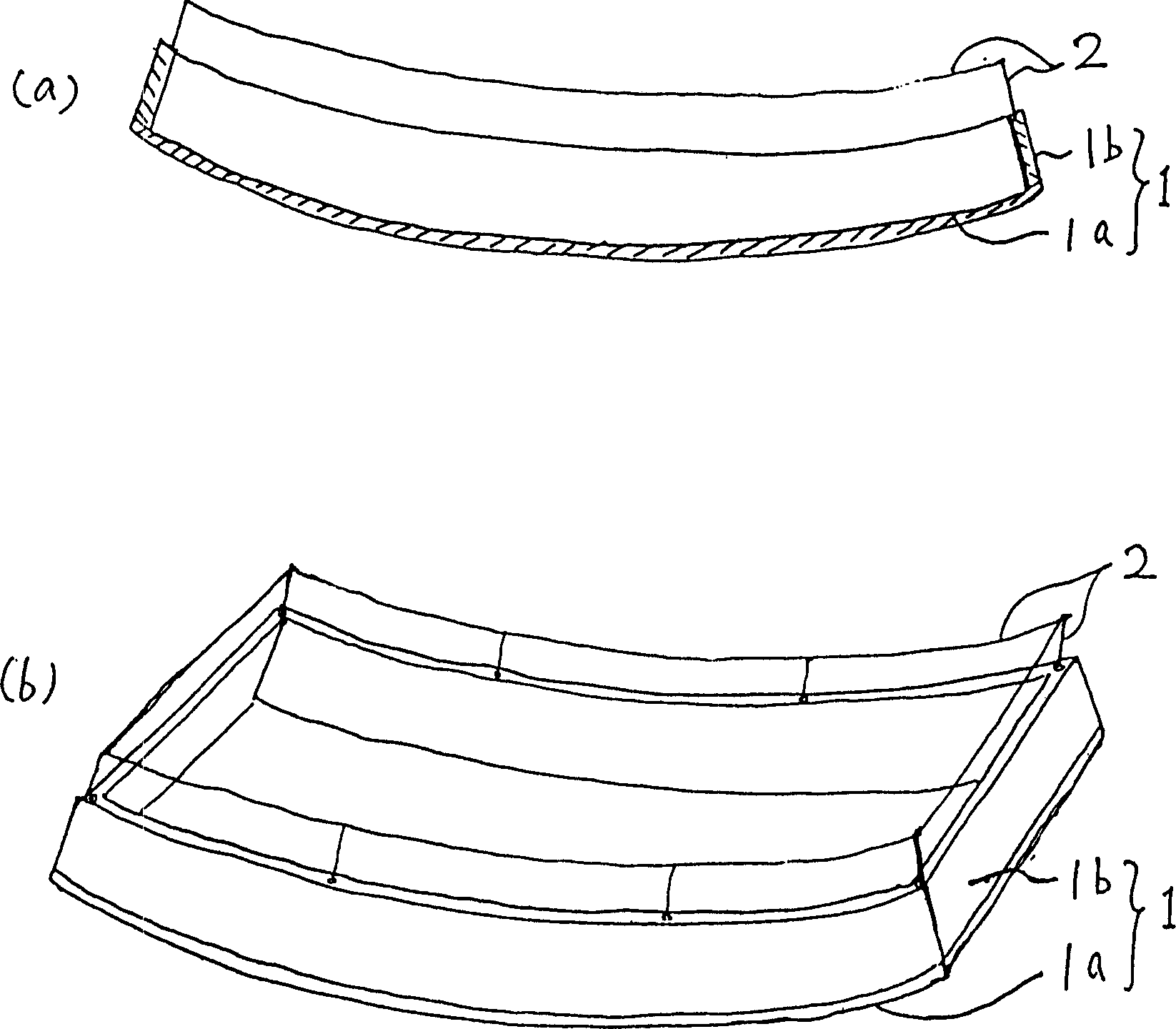

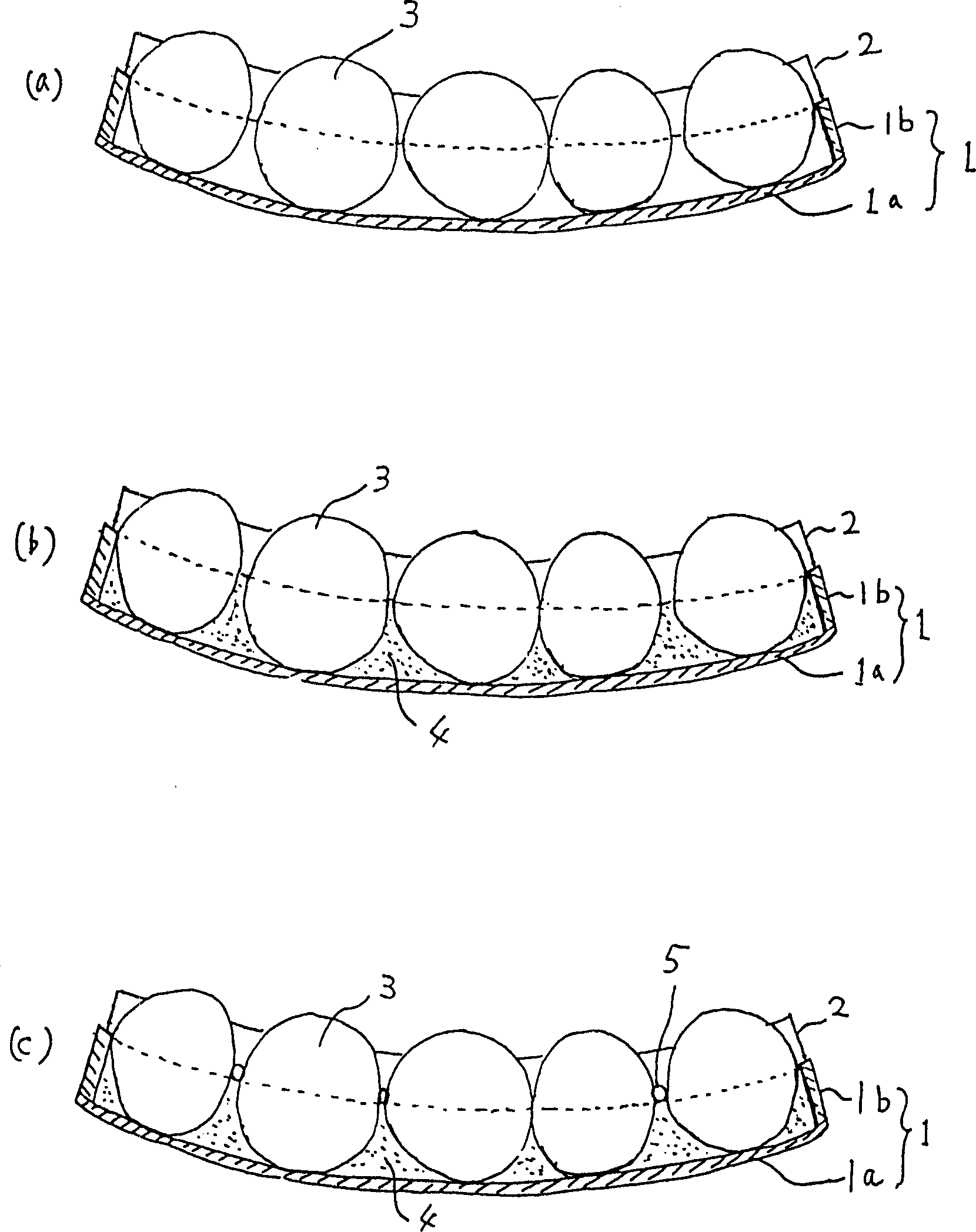

[0036] Embodiment 1: the following reference Figure 1-4 Each working procedure of the manufacturing method of the natural stone brick board is described with respect to Embodiment 1 of the present invention. In this embodiment 1, first, prepare as figure 1 Sectional drawing of (a) and figure 1 (b) is an oblique view of the lower frame 1 shown. The bottom surface of the bottom plate 1a of the lower frame 1 is concavely curved to form a curved surface. In addition, the side 1b formed by the four sides of the aforementioned lower frame 1 is that the top and bottom of the front and rear sides in the figure extend in parallel with the curved surface of the bottom plate (and the side 1b of the lower frame 1 is left and right in the figure). 2 sides are rectangular), the aforementioned lower frame 1 can be fixed by the base plate 1a and the side 1b during manufacture, and can also be installed with rivets at the parapet construction site.

[0037] Next, the figure 2 Sectional ...

Embodiment 2

[0047] Embodiment 2: Embodiment 2 of the present invention is with reference to Figure 6 to Figure 10 to explain. In addition, with regard to the following articles, if there are any related to the aforementioned Example 1 Figure 1 to Figure 5 Duplicate parts of the description are omitted.

[0048] In this embodiment 2, first, according to the section Image 6 (a) and slope Image 6 As shown in (b), prepare a lower frame consisting of a base plate 11a with a convex curved surface and a side surface 11b whose upper and lower end curvatures of the front and rear sides are parallel to the curved surface of the aforementioned base plate 11a as shown in the figure. 11.

[0049] Next, follow the section Figure 7 (a) and slope Figure 7 As shown in (b), on the upper surface of the side surface 11 (b) of the lower frame 11, the baffle plate 12 made of steel bar is attached. This baffle plate 12 is to prevent large natural stones from rolling to the outside from the side 11 ...

Embodiment 3

[0058] Embodiment 3: Embodiment 3 of the present invention is based on reference Figure 11 to explain. First, if Figure 11 As shown in (a), the lower frame 21 is prepared to be formed from a flat bottom plate 21a and four rectangular side plates 21b. Then, the upper surface of the bottom plate 21a of the lower frame 21 is covered with sand 24 . The sand 24 at this time is spread to form the concave curved surface 24a shown in the figure.

[0059] Next, follow the Figure 11As shown in (b), a plurality of large natural stones 23 are arranged on the aforementioned sand 24 forming the curved surface 24a. At this time, the aforementioned plurality of large natural stones 23 are closely arranged in order to have as little or no space as possible between each other.

[0060] Next, follow the Figure 11 As shown in (c), the sand 24b is spread from above the large natural stones, and flows down from the gaps between the large natural stones 23, and accumulates on the aforement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com